Ingcaciso yeMveliso

Ncamathelisa: ngaphantsi kwe-300℃

Ukuwelda: ngaphantsi kwe-600 ℃

Umsesane: ngaphantsi kwe-1000℃

I-Silicon Carbide: ngaphantsi kwe-1300 ℃

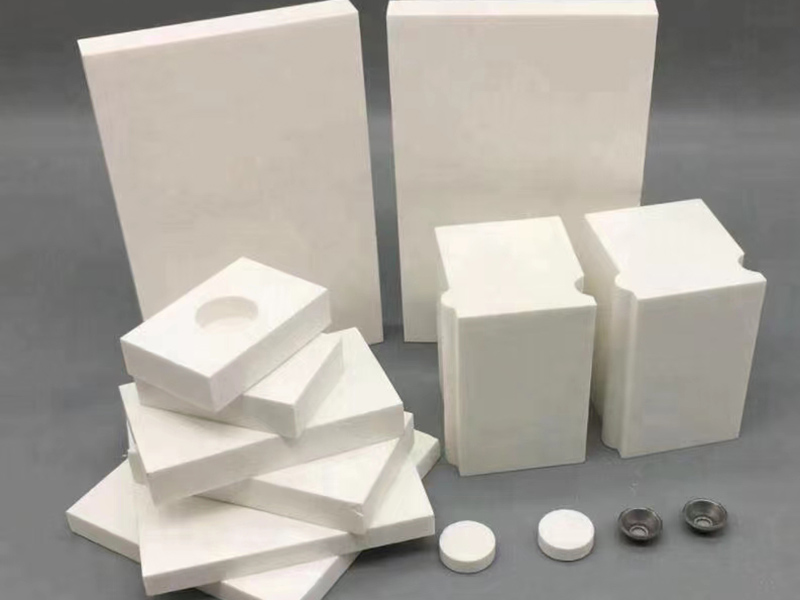

Inxalenye ephambili ye-SHC enganyangekiyo kwi-ceramic yi-92% ye-Alumina kunye ne-95% ye-Alumina Ceramic kunye nokusebenza okugqwesileyo kunye nexabiso elihle kunye neyona nto isetyenziswa kakhulu. Uxinaniso oluphezulu, ubulukhuni bedayimani obufana nobulukhuni, ukutya okuziinkozo okucokisekileyo okucwangcisiweyo kunye namandla aphezulu omatshini ziipropathi ezikhethekileyo ezenza kube yimathiriyeli yokuzikhethela kuluhlu olubanzi lwezicelo ezifunayo. Ngenxa yeepropathi ze-insulating, ihlala isetyenziswa kwiimveliso zombane.

Iimpawu zobugcisa bethayile yeCeramic

Umxholo we-AL2O3: >92%

Ubuninzi: 3.6g/cm3

Ukuqina kweRockwell: HRA 85

Ukuqhaqha ubunzima: 4 MPa.ml/2

Amandla okumelana noxinzelelo:>850 MPa

Ukugoba ukumelana: 300 MPa

I-Thermal conductivity: 24 W / mK

I-coefficient yokwandisa i-Thermal: 50-83 10-6 m / mK

Imveliso eluncedo

1. Ukuxhathisa okugqwesileyo kokunxiba:ukwamkela ubulukhuni obuphezulu be-alumina ceramics njengomgca, ubomi bombhobho bungaphezu kwamaxesha ali-10 kunentsimbi eqhelekileyo eqinile.

2. Ukumelana nokuMhlwa:I-alumina ceramic ineenzuzo zokukhukuliseka kwamanzi olwandle, i-asidi kunye nokumelana ne-alkali, kunye nokukhuselwa komgangatho.

3. Unyuselo lwefriction:Umphezulu wangaphakathi ogudileyo kwaye ngaphandle kokukhukuliseka, ukugudisa kwangaphakathi kwemibhobho kuphezulu kunanoma yiyiphi enye imibhobho yesinyithi.

4. Ubunzima obulula:Ubunzima bombhobho we-ceramic onemigca ehlanganisiweyo sele ufikile kwisiqingatha sombhobho welitye kwaye malunga ne-50% yombhobho wealloyi. Ngokuxhathisa kunye nokumelana nomhlwa, ixesha lokuphila kombhobho we-ceramic linelinen lide ngokugqithisileyo kunezinye iipayipi ezixhathisayo, ngoko ke iindleko zokuhlanganisa kunye nokusebenza 5.