Ukukhetha ekuneneoomatshini bokutyumza imihlathiidlala indima ebalulekileyo ekusebenzeni kakuhle. Aba matshini babalulekile kumashishini afana nemigodi kunye nokwakha, apho bakhonaukwandisa imveliso ngokophula izixhobo ezinkulu. Iimpawu eziphambili, ezifana nobuchwepheshe obuphambili kunye neeparamitha zoyilo, zichaphazela kakhulu ukusebenza kunye nokuthembeka. Umzekelo, oomatshini abane-hydraulic drives kunye neepaneli zokulawula ezisebenzisekayo zinokunyusa ukuphuma kunye nokunciphisa ixesha lokuphumla. Ukongeza, ukuqonda ezahlukeneyoiindawo zokutyumza umhlathi, kuqukaiindawo zokugutyula imihlathi, ibalulekile ekugcinweni nasekuphileni ixesha elide. Iiyantlukwano phakathi kweempawu kunye neemodeli, ezifana nobungakanani bokutya kunye nokuhamba, zichaphazela ngakumbi ukusebenza koomatshini bokutyumza imihlathi, ngelixa kuqwalaselwa ukubalulekaiindawo zokutyumza ilityekwayeiinxalenye ezisecaleni zeconyikwimpumelelo yokusebenza ngokubanzi.

Izinto eziphambili zokuThatha

- Ukukhetha isityuli somhlathi wasekunenekuphucula ukusebenza kakuhle. Gxininisa kwiimpawu ezinjengokutyumza umthamo kunye nokuphatheka ukuhlangabezana neemfuno zakho ezithile.

- Izinto ezikumgangatho ophezulu, ezifanaintsimbi ephezulu yemanganese, ukuphucula ukuqina kunye nobomi. Khetha oomatshini abakhiwe ngezinto ezinamandla zokunciphisa ukuguga nokukrazula.

- Ukugcinwa rhoqo kubalulekile kwintsebenzo. Cwangcisa uhlolo kwaye ugcine iinxalenye ezisecaleni zifumaneka ngokulula ukunciphisa ixesha lokuphumla kunye neendleko zokulungisa.

- Ukuqonda umthamo wokutyumza kunye nomlinganiselo wokunciphisa kunceda ekukhetheni umatshini ochanekileyo. Qinisekisa ukuba imodeli ihambelana neenjongo zakho zemveliso ukuze ufumane iziphumo ezizezona zilungileyo.

- Inkxaso emva kokuthengisa, kubandakanywa iziqinisekiso kunye noqeqesho, kubalulekile. Iinkqubo zenkxaso ezomeleleyo zonyusa ixabiso lomatshini kwaye ziqinisekisa ukusebenza okusebenzayo.

Yila kunye noKwakha uMgangatho woomatshini bokutyumza imihlathi

Iuyila kwaye wakhe umgangathokoomatshini bokutyumza imihlathi banempembelelo enkulu ekusebenzeni kwabo kunye nobomi obude. Abavelisi babeka phambili ukusebenzisa imathiriyeli ekumgangatho ophezulu ukuqinisa ukuqina. Ngokomzekelo, intsimbi ephezulu ye-manganese inokubonelela ubomi obuyiyo30-50% ubudexa kuthelekiswa nezinto eziqhelekileyo. Olu khetho lwezinto eziphathekayo alugcini nje ukunyusa ukuqina kodwa luqinisekisa ukuba oomatshini banokumelana nobunzima bokusetyenziswa kakhulu.

Izinto Ezisetyenziswayo

Abavelisi abaphezulu bagxininisainguqulelo kuyilo lwemveliso. Batyala imali kuphando kunye nophuhliso ukwenza itekhnoloji ephezulu kunye nezixhobo. Oku kuzibophelela kukhokelela koomatshini bokutyumza imihlathi abasebenzayo nabathembekileyo. Ukuqina kunye nokuqina kwemathiriyeli yesondlo nako kudlala indima ebalulekileyo kumazinga okunxiba, okuphembelela ubomi besixhobo. Ukuhlolwa rhoqo kunokwandisa ubomi benxalenye ukuya kuthi ga kwi-30%, kwandisa ubomi bubonke ngolondolozo olusebenzayo.

IMfezeko yoLwakhiwo

Ukuthembeka kolwakhiwo kubalulekile kwimpumelelo yokusebenza koomatshini bokutyumza imihlathi. Izakhelo ezinamandla kunye nobunjineli obufanelekileyo zithintela ukuguqulwa phantsi kwemithwalo enzima. Lo mgangatho uqinisekisa ukuba oomatshini bagcina ukusebenza kwabo ngexesha. Ukusebenzisa iindawo ezikwaziyo ukumelana nokunxitywa kunokunciphisa ukutshintshwa nge-35%, ukunciphisa ixesha lokuphumla kunye nokwandisa ubomi bokusebenza. Ukusebenzisana phakathi kweepleyiti zemihlathi kunye nezinto eziphathekayo kukhokelela ekunxibeni okubalulekileyo, okunokunciphisa ukusebenza kakuhle kunye nokunyusa ukusetyenziswa kwamandla.

Iimpawu zokuphatheka

Iimpawu zokuphatheka zibalulekile kumashishini amaninzi. Umatshini wokutyumza umhlathi ophathwayo uvumela ukuthuthwa lula phakathi kweendawo zomsebenzi. Oku bhetyebhetye kunokwandisa imveliso kunye nokunciphisa iindleko zokusebenza. Abavelisi be-Elite banikezela ngoluhlu olubanzi lwee-crushers ezilungiselelwe imisebenzi eyahlukeneyo, ebonisa ukuqonda kwabo iimfuno zemarike ezahlukeneyo. Ukongeza, iinkqubo zenkxaso ezomeleleyo, kubandakanywa ukufikelela ngokukhawuleza kwiindawo ezisecaleni kunye nokugcinwa, kubalulekile ekunciphiseni ixesha lokuphumla.

Iimetriki zokuSebenza koomatshini bokutyumza imihlathi

Imilinganiselo yokusebenzadlala indima ebalulekileyo ekuvavanyeni oomatshini bokutyumza imihlathi. Ezi metrics zinceda abasebenzisi ukuba baqonde ukuba umatshini unokusebenza kakuhle kangakanani kwizicelo ezahlukeneyo. Iimethrikhi ezintathu eziphambili zokusebenza ziquka ukutyumza umthamo, umlinganiselo wokunciphisa, kunye nokusebenza kakuhle kwamandla.

Ukutyumza amandla

Umthamo wokutyumza ubhekisa kubungakanani bezinto ezinokwenziwa sisityutyuzi somhlathi ngexesha elithile. Le metric ibalulekile ekumiseleni ukufaneleka komatshini kwimisebenzi ethile. Iimodeli ezahlukeneyo zibonisa amandla ahlukeneyo ngokusekelwe kuyilo kunye neeparamitha zokusebenza.

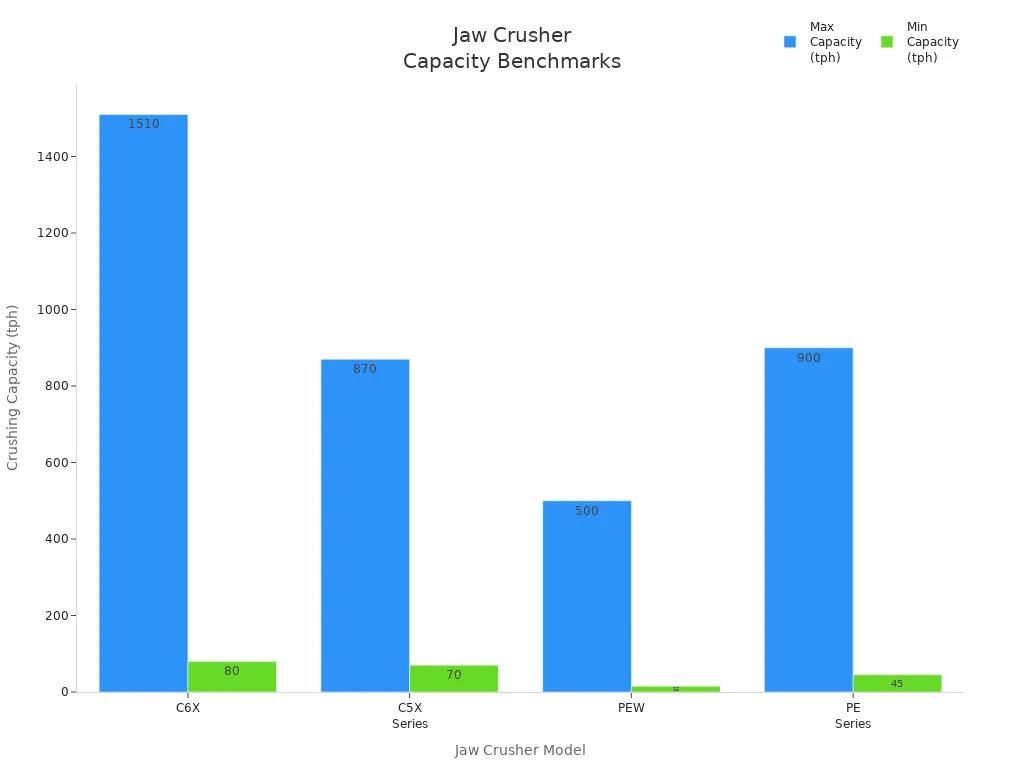

Nantsi itheyibhile ebonisa amandla okutyumza kweemodeli ezidumileyo zesityuli somhlathi:

| Umzekelo | Ubungakanani begalelo | Umthamo (tph) | Usetyenziso |

|---|---|---|---|

| C6X | 0-1280mm | 80-1510TPH | Imigodi emikhulu, iiprojekthi zeziseko ezingundoqo |

| Uluhlu lweC5X | 0-920mm | 70-870TPH | Imisebenzi ephakathi ukuya kwezikakhulu |

| I-PEW | 80-1510TPH | 15-500TPH | Ukwembiwa kwemigodi okuphakathi, imveliso edibeneyo |

| PE Series | 0-1020mm | 45-900TPH | Imisebenzi emincinci ukuya kwephakathi |

Abaliqelaizinto ziphembelela amandla okutyumza, kuquka:

- Uyilo lwesiqhekeza: Iimodeli ezahlukeneyo, njengeentlobo zeDodge kunye neBlake, zinoyilo olulodwa oluchaphazela umthamo.

- Iengile phakathi kwemihlathi: Ukuncipha kwe-angle kunokunciphisa ukuxinana kwelitye, ukuchaphazela umthamo.

- Isantya sokusebenza: Ukwahluka kwisantya kunokuchaphazela umthamo, kunye neziphumo ezahlukeneyo kwisantya esicothayo kunye nesantya esiphezulu.

- Imeko yobuso bomhlathi: Ukunxiba kunye nemeko yobuso bomhlathi kunokuchaphazela ukusebenza kakuhle kokutyumza.

- Ubungakanani bentshukumo yomhlathi: I-amplitudes enkulu ingakhokelela ekunyuseni ngokukhawuleza kweetoni zethiyori, ezichaphazela umphumo wangempela.

- Uburhabaxa bomphezulu womhlathi: Ukunyuka koburhabaxa kunokunciphisa ukuhlala kwendawo yokufuduka, ukuchaphazela umthamo.

Umlinganiselo wokuNcitshiswa

Umlinganiselo wokunciphisa ulinganisa ukuba ingakanani i-crusher yomhlathi inciphisa ubungakanani bezinto zokufaka. Lo mlinganiselo ubalulekile ekuqondeni ukusebenza kakuhle kwenkqubo yokutyumza. Izityumli zemihlathi ephezulu zidla ngokufezekisa aumlinganiselo wokunciphisa ukusuka ku-6:1 ukuya ku-8:1kwizityuli eziziiprayimari, 3:1 ukuya ku-5:1 kwizityuli zesibini, kunye ne-2:1 ukuya ku-3:1 kwizityuli zamabanga aphakamileyo.

Umlinganiselo wokunciphisa uchaphazela kakhulu ukusebenza kakuhle kwezityuli zomhlathi ngokumisela ubungakanani bezinto eziphumayo kunye nomthamo wokuvelisa. Igumbi elikrwitshiweyo linyusa umthamo wemveliso kwaye liqinisekisa ubungakanani bamasuntswana afanayo. Ngokwahlukileyo koko, igumbi elingaxutywanga lingakhokelela ekunciphiseni ukusebenza kakuhle kunye nokuma kwesuntswana elibi.

- Igumbi elikrwitshiweyo likhulisa umthamo wemvelisokwaye ivelise amasuntswana aqhekekileyo ngokufanayo.

- Igumbi elingagxininisi linganciphisa ukusebenza kakuhle kwaye lichaphazele kakubi imilo yamasuntswana.

Izityumli zemihlathi ziminxeka ziyimfunekoukwandisa umthamo wemvelisokunye nokuqinisekisa ukwaphuka kwamasuntswana afanayo. Ngokuchaseneyo, ukondla ngobuchule kunokukhokelela kwizohlwayo ezimbalwa kodwa kuchaphazela kakubi imilo yamasuntswana kunye nomthamo wokuphuma, ekugqibeleni kuthintele ukusebenza kakuhle.

Ukusebenza kakuhle kwamandla

Ukusebenza kakuhle kwamandla yeyona metric yokusebenza ebalulekileyo koomatshini bokutyumza imihlathi. Inkqubela phambili yangoku igxile ekwandiseni ukusetyenziswa kwamandla ngelixa kugcinwa ukusebenza okuphezulu. Iinguqulelo eziphambili ziquka:

- Iinkqubo ezidityanisiweyo zokuqhuba ezenza ukusetyenziswa kwamandla ngokupheleleyo.

- Iiparamitha zokutyumza ezilungelelanisiweyo ezinciphisa ukusetyenziswa kwamandla.

- Ukugxila ekuzinzeni kwimisebenzi yemigodi.

Umzekelo, izityumli ezixutyiweyo zeRM Group zizuza ukucutha iindleko zepetroli ngama-25% xa kuthelekiswa neemodeli zemveli. Ukugcinwa kwamafutha ngamafutha kunokufikelela kwi-50% xa kudityaniswa nezikrini ezixubileyo.

Uphuculo lwamva nje lukwabandakanya:

- Iisetingi ze-Hydraulic wedge zohlengahlengiso olulula.

- Iimotor eziphambili zamandla aphezulu.

- Ukhuseleko oluphuculweyo kunye neempawu zokusebenza.

Izityumsi zangoku eziphezulu, njenge-C6X, ziyilelwe ukwandisa ukusetyenziswa kwamandla. Ukwenziwa kwezinto ezintsha kuyilo kukhokelela ekuphuculweni kobuchule bokusebenza ngokudibeneyo.

Nantsi itheyibhile ethelekisa amazinga okusetyenziswa kwamandla phakathi kweemodeli ezidumileyo zesityumzo somhlathi:

| Amandla oxinzelelo (MPa) | Ukusetyenziswa koMbane (Isihlobo) |

|---|---|

| 28 | 1 |

| 90 | 4 |

Ezi nkqubela phambili zinegaleloimilenze yekhabhoni encitshisiweyokunye nokulungelelanisa nokuqiniswa kwemigaqo yozinzo kushishino.

Ukufaneleka kweSicelo seMithi yokutyumza oomatshini

Oomatshini bokutyumza imihlathi bayagqwesakwizicelo ezahlukeneyo ngenxa yokuguquguquka kwazo kunye nokusebenza kakuhle. Ukuqonda iintlobo zezixhobo abazenzayo, izicelo zabo ezibhekiselele kwishishini, kunye nokulinganisa kwabo kunye nokuguquguquka kunokunceda abasebenzisi benze izigqibo ezinolwazi.

Iintlobo zeMathiriyeli eSebenzisiweyo

Izityumza zemihlathi zibamba uluhlu olubanzi lwezixhobo, zizenza zilungele amashishini ahlukeneyo. Ngokweengxelo zeshishini, ezona zinto zisetyenzwayo zibandakanya:

| Icandelo | Izinto eziQhelekileyo eziSetyenzwayo | Ukwabelana kwimakethi (%) |

|---|---|---|

| Ukwembiwa kwemigodi | Intsimbi yentsimbi, amalahle, ubhedu, izinto ezinegolide | 68 |

| Ukwakhiwa | I-aggregates, igrabile, inkunkuma yokudiliza | 22 |

Iukusebenza kwezityumli zemihlathiiyahluka ngokusekelwe kubulukhuni bezinto eziphathekayo. Ngokomzekelo, izinto ezinzima ezifana ne-granite (ubunzima be-Mohs ye-7) zifuna amandla amaninzi ukutyumza. Oku kukhokelela ekuphumeni okuphantsi xa kuthelekiswa nezinto ezithambileyo, ezifana nekhonkrithi (ubunzima be-Mohs ye-5). Nazi ezinye iimbono malunga nobunzima bezinto eziphathekayo:

- Izinto ezinzima zifuna amandla amaninzi, okukhokelela ekuphumeni okuphantsi.

- Igranite etyumzayo inokuvelisa malunga nemvelisoIitoni ezili-10 ngeyure (TPH).

- Izinto ezithambileyo ezifana nekhonkrithi zinokufikelela kuma-50 TPH phantsi kweemeko ezifanayo.

- Ukuqonda isikali sobulukhuni be-Mohs kubalulekile ekuqikeleleni i-output kunye nokwandisa iiparamitha zokusebenza.

Izicelo ezingqale kwishishini

Oomatshini bokutyumza imihlathi bakhonza amashishini ahlukeneyo, ngalinye lineemfuno ezizodwa. Nazi iizicelo eziphambili:

- Ishishini lezemigodi: Izityuli zemihlathi zityumza amatye amakhulu abe ngamaqhekeza amancinci, alungisa ore njengentsimbi, ubhedu, igolide kunye nesilivere.

- Ishishini lokumbiwa kweekwari: Batyumza amatye, ikhonkile, netela xa kusenziwa umsebenzi wokwakha.

- Ishishini loKwakha: Idla ngokusetyenziselwa ukuhlaziya izinto ezifana nekhonkrithi kunye ne-asphalt kulwakhiwo lweendlela kunye neeprojekthi zokwakha.

- Ishishini lokuRecycling: Isebenza ngokucumza imathiriyeli eyohlukeneyo, kuquka iglasi, iplastiki, isinyithi, kunye nephepha, ngakumbi ekuhlaziyeni izinto ezinzima njengenkunkuma yombane.

Amashishini awohlukeneyo anento ethileiimfuno zesicelo. Le theyibhile ilandelayo ishwankathela ezi mfuno:

| Ishishini | IiMfuno zesicelo | ImiSebenzi ePhambili |

|---|---|---|

| Ukwembiwa kwemigodi | Ukutyunyuzwa okuphambili kwezinto ezinzima kunye ne-abrasive, ukunciphisa ubungakanani be-ore ukuze kuqhutywe | Ukutsalwa kwentsimbi ekrwada, ukuphatha imathiriyeli, imveliso edityanisiweyo, isampulu yejoloji, ukhuseleko kunye nemveliso |

| Ukwakhiwa | Ikhonkrithi etyumzayo, izitena, amatye, kunye nezinye izinto zophuhliso lweziseko ezingundoqo | Ukudilizwa, ukwakhiwa kweendlela, umsebenzi wesiseko, uhlaziyo, ukucoca indawo, ukuphatha imathiriyeli |

| Ukurisayikilisha | Ukutyumza kunye nokunciphisa izinto ezifana nekhonkrithi kunye ne-asphalt kwiifom ezinokusetyenziswa kwakhona | Imisebenzi yokuhlaziya, ukucuthwa kwenkunkuma, ulondolozo lwemithombo |

I-Scalability kunye nokuguquguquka

I-scalability kunye nokuguquguquka zizinto ezibalulekileyo koomatshini bokutyumza imihlathi. Baziqhelanisa nobukhulu obahlukeneyo bokusebenza kunye neemfuno zeprojekthi. Izityumli zomhlathi ophakathi zikholisa ukuba namandla ukusuka200 ukuba 500 tph, izenza zilungele izicelo ezinjengokwembiwa kunye nokurisayikilisha. Izityumli zemihlathi emikhulu zinokugqitha kwi-500 tph, kunye nezinye iimodeli zisetyenzwa ukuya kuthi ga kwi-1,500 tph, zilungele usetyenziso olunzima. Izinto ezichaphazela amandla ziquka:

- Ubungakanani be-crusher

- Ubungakanani bokutya

- Iimpawu zezinto eziphathekayo

- Iiparamitha zokusebenza

- Isantya sokusebenza

- Umxholo wokufuma kwezinto

Iimpawu zokuguquguquka ziphucula ukuziqhelanisa nokutshintsha iimfuno zeprojekthi. Umzekelo, ukuvuleka okuhlengahlengiswayo kokukhutshwa kuvumela ukulawula ubungakanani bemveliso. Esi sikhundla senza ukuba kuveliswe zombini amaqhekeza arhabaxa kunye nembudumbudu ecolekileyo. Nasi isishwankathelo seempawu zokuguquguquka:

| Uphawu | Inkcazo |

|---|---|

| Ukuguquguquka kubungakanani besiphumo | Ukusetwa kwecala elivaliweyo (CSS) kunokuhlengahlengiswa ukutshintsha ubungakanani bemveliso kwiimfuno ezahlukeneyo zokutyumza. |

| Ukuguquguquka | Ilungele imisebenzi ukusuka ekuqhekezeni amatye amakhulu ukuya ekuveliseni amatye acoliweyo. |

Izityumza zemihlathi ziyaziwa ngokusebenza kwazo kunye nokuguquguquka, zizenza ukhetho olukhethwayo kwizicelo ezahlukeneyo zemizi-mveliso ngenxa yokukwazi ukuhlangabezana neemfuno zeprojekthi eziguqukayo.

Iingqwalaselo zoLondolozo koomatshini beMihlathi yokutyumza

Ukugcina oomatshini bokutyumza imihlathikubalulekile ekuqinisekiseni ubomi obude kunye nokusebenza kwabo. Iindlela zogcino olululo zinokunciphisa kakhulu ixesha lokuphumla kunye nokwandisa imveliso.

UkuLula kweSondlo

Ukulula ukugcinwa kuchaphazela ngqo iindleko ezipheleleyo zobunini kwizityuli zemihlathi. Ukugcinwa rhoqo kunceda ukuthintela ukulungiswa okuxabisa imali eninzi kwaye kugcina oomatshini besebenza kakuhle. Abaqhubi bahlala bejongana nemingeni, efana nale:

- Ingxolo engaqhelekanga ngexesha lokusebenza, ebonisa iindawo ezikhululekileyo okanye izinto ezigugileyo.

- Ukunciphisa amandla okutyumza, okukhokelela ekunciphiseni imveliso.

- Ukungcangcazela okugqithisileyo okuchaphazela uzinzo kunye nokubangela ukuguga kwangaphambili kwamacandelo.

Iinkqubo zogcino olusebenzayo zinokuyinciphisa le miba. Abanini-zithuthi kufuneka babeke phambili ufikelelo olulula kumalungu angaphakathi. Uphando lubonisa ukubaukuya kuthi ga kwi-40% yexesha lokulondolozainokuchithwa ekuchitheni nasekuhlanganiseni kwakhona. Ukwenza lula le nkqubo kunokukhokelela ekongeni ixesha elibalulekileyo.

Ubukho bezahlulo eziSpare

Iukufumaneka kweendawo ezisecaleniyenye into ebalulekileyo ekugcineni izityumzi zemihlathi. Ukufikelela ngokukhawuleza kwiindawo ezitshintshileyo kuqinisekisa ixesha elincinci lokuphumla. Nasi isishwankathelo sokufumaneka kweendawo ezisecaleni kwiibhrendi eziphambili:

| Uphawu | Ubukho bezahlulo eziSpare |

|---|---|

| Terex | Indawo entsha ye-Jaw Crusher Wear Parts ekhoyo |

| Sandvik | Indawo entsha ye-Jaw Crusher Wear Parts ekhoyo |

| Isikrini samandla | Indawo entsha ye-Jaw Crusher Wear Parts ekhoyo |

| Umvukeli | Indawo entsha ye-Jaw Crusher Wear Parts ekhoyo |

| Extec | Indawo entsha ye-Jaw Crusher Wear Parts ekhoyo |

| Finlay | Indawo entsha ye-Jaw Crusher Wear Parts ekhoyo |

Iimveliso ezifana ne-GTEK Mining zikwabonelela ngamacandelo akhelwe ubomi benkonzo ende, ukuqinisekisa ukuba abaqhubi banokufumana iinxalenye zokunxitywa kwemihla ngemihla okanye ukonakaliswa okungalindelekanga.

Iindleko zoLondolozo

Iindleko zokuyigcina zinokwahluka kakhulukubo bonke abavelisi kunye nezicelo ezahlukeneyo. Nalu uthelekiso lweendleko zogcino eziqhelekileyo ezisekelwe kuhlobo lwesicelo:

| Uhlobo lwesicelo | Uluhlu lweXabiso lokuThenga oluQhelekileyo | Iindleko zoLondolozo |

|---|---|---|

| Ukwembiwa kwemigodi kunye nomsebenzi onzima | $$$$ | Phakathi ukuya Phezulu |

| IMveliso eDityanisiweyo | $$$ | Phakathi |

| Ulwakhiwo oluNcinci | $$ | Phantsi |

Iindleko zonyaka zokugcinwa kwezityumli zemihlathi ziqhele ukusuka kwi- $15,000 ukuya kwi- $25,000 ngeyunithi nganye. Ezi ndleko zixhomekeke kubukhulu bokusetyenziswa kunye neemeko zokusingqongileyo. Ngokuqonda ezi zinto, abaqhubi banokwenza izigqibo ezizizo ezonyusa ukusebenza kakuhle kunye nokuthembeka koomatshini babo bokutyumza imihlathi.

Inkxaso emva koThengiso lweeMashini ze-Jaw Crusher

Emva kokuthenga i-crusher yomhlathi,inkxaso emva kokuthengisa iba yinto ebalulekileyoukunyusa ixabiso layo. Iinkqubo zenkxaso ezomeleleyo zinokuphucula kakhulu ukusebenza kakuhle kwaye ziqinisekise ukwaneliseka kwexesha elide.

Iwaranti kunye neziVumelwano zeNkonzo

Abenzi abaphambili bemihlathi yokutyumza badla ngokunikezelaiwaranti eyomeleleyo kunye nezivumelwano zenkonzo. Ezi zivumelwano zinika uxolo lwengqondo kwaye zikhusela utyalo-mali. Nasi isishwankathelo semigaqo yewaranti esemgangathweni:

| Umba | Iinkcukacha |

|---|---|

| Ixesha lewaranti | Iminyaka emibini ukusuka kumhla wokumiselwa kokuqala. |

| Ukhuseleko | Izincedisi ezitsha zokutshintshwa kunye nokulungiswa ukuba ayingomonakalo owenziwe ngumntu. |

| Uxhaso lobuchwepheshe | Ubomi benkxaso yobugcisa yasimahla bubonelelwe. |

| Ixesha lokuphendula | Imiba yabaThengi isonjululwe kwiiyure ezingama-24, yasonjululwa kwiiyure ezingama-72. |

Iziqinisekiso ezinjalo zibonisa ukuzithemba kwabavelisi kwiimveliso zabo. Bakwaqinisekisa ukuba abathengi bafumana uncedo ngexesha elifanelekileyo xa lufuneka.

Ubukho beNkxaso yoMthengi

Ukufumaneka kwenkxaso yomthengi yenye into ebalulekileyo. Abavelisi abaphezulu banikezela ngamaqela enkxaso azinikeleyo ukunceda abasebenzisi. Iimpendulo ezikhawulezayo kwimibuzo zinokunciphisa ixesha lokuphumla kwaye ziphucule imveliso. Iinkampani ezininzi zibonelela ngeendlela ezininzi zenkxaso, kubandakanya ifowuni, i-imeyile, kunye nencoko ephilayo. Oku kufikeleleka kuqinisekisa ukuba abaqhubi banokusombulula imiba ngokufanelekileyo, okubavumela ukuba bagxininise kwimisebenzi yabo ephambili.

Uqeqesho kunye neZibonelelo

Iinkqubo zoqeqesho ezinikezelwa ngabavelisi zidlala indima ebalulekileyo ekusebenziseni ngokufanelekileyo oomatshini bokutyumza imihlathi.Abaqhubi abaqeqeshwe kakuhle banokusabela kwimingeni ngokufanelekileyo. Nazi ezinye iingenelo eziphambili zezi nkqubo zoqeqesho:

- Uqeqesho lomsebenzisi lubalulekile kusetyenziso olukhuselekileyo lwezixhobo.

- Iikhosi zokuhlaziya rhoqo zigcina abaqhubi behlaziywa ngetekhnoloji kunye neendlela zokhuseleko.

- Uqeqesho lulungiselelwe umatshini kunye nendawo yomsebenzi.

Ezi nkqubo zinciphisa iimpazamo kwaye ziphucula ukhuseleko kwindawo yokusebenza. Bakwaphucula ixesha elide lezixhobo ngokuqinisekisa ukusetyenziswa ngokufanelekileyo. AbaSebenzisi bafunda ukulungisa iingxaki ezisisiseko kwisiza, ukufumana ingxelo ekhawulezileyo enceda ukongeza ukusebenza komatshini. Utyalo-mali kuqeqesho alunyusi imveliso kuphela kodwa lukwakhuthaza inkcubeko yokhuseleko nokusebenza kakuhle.

Ngamafutshane, ukukhetha oomatshini bokutyumza imihlathi ekunene kubandakanya ukuqonda izinto ezininzi ezibalulekileyo. Imiba ephambili ibandakanyaamandla okutyumza, ubungakanani besondlo, ulungelelwaniso lwemveliso, kunye nokuphatheka. Ezi mpawu zinempembelelo enkulu ekusebenzeni kakuhle kunye nemveliso jikelele.

Qwalasela le miba xa uthenga:

- Ukutyumza amandla: Qinisekisa ukuba ihambelana neenjongo zemveliso.

- Ubungakanani bokutya: Tshatisa umatshini kunye nobukhulu bezinto zakho.

- Ukulungelelaniswa: Khangela useto oluvumela ulawulo phezu kobungakanani bemveliso.

- Ukuphatheka: Khetha ngokusekelwe kwiimfuno zesayithi kunye nokulula.

Ngokubeka phambili ezi mpawu, abaqhubi banokwenza izigqibo ezizizo ezihlangabezana neemfuno zabo ezithile.Izifundo eziyimpumelelo, njengeprojekthi yemigodi yaseMzantsi Afrika kunye ne-Uganda granite plant, ibonisa iingenelo zokukhetha oomatshini ngokusekelwe kwezi mpawu.

FAQ

Yintoni umsebenzi ophambili womatshini wokutyumza imihlathi?

Oomatshini bokutyumza imihlathi batyumza amatye amakhulu abe ngamaqhekeza amancinci, alawulekayo. Bagqwesa ekwaphuleni izinto eziqinileyo ezifana negranite, i-limestone, kunye nentsimbi ekrwada, nto leyo ezenza zibaluleke kakhulu kwimigodi nemizi-mveliso yokwakha.

Ndikhetha njani isityuli somhlathi esifanelekileyo kwiimfuno zam?

Qwalasela izinto ezifana nomthamo wokutyumza, ubungakanani bokutya, kunye nohlobo lwemathiriyeli. Vavanya iimfuno zakho zesicelo kwaye ukhethe imodeli ehambelana neenjongo zakho zokuvelisa kunye neemeko zokusebenza.

Zeziphi izenzo zogcino ekufuneka ndizilandele kwizityuli zemihlathi?

Zihlole rhoqo izinto ezinxitywayo, qinisekisa ukuthambisa okufanelekileyo, kwaye ucoce umatshini ukunqanda ukugcwala kobutyobo. Cwangcisa ulondolozo lwesiqhelo ukujongana nemiba enokubakho ngaphambi kokuba inyuke.

Ngaba iindawo ezisecaleni zifumaneka lula kwizityuli zemihlathi?

Ewe, abaninzi abavelisi abahloniphekileyo banikezela uluhlu olubanzi lwamacandelo angasese. Ukufikelela ngokukhawuleza kula macandelo kunciphisa ixesha lokuphumla kwaye kuqinisekisa ukusebenza kakuhle, ukuphucula imveliso yonke.

Ndingawuphucula njani amandla okusebenza kwesityumzi somhlathi wam?

Lungiselela iiparamitha zokusebenza, ezifana nokulungelelanisa isantya sokutyumza kunye nesantya sokutya. Ukugcinwa rhoqo kunye nokusetyenziswa kweemodeli eziphezulu kakhulu kunokunciphisa kakhulu ukusetyenziswa kwamandla kunye neendleko zokusebenza.

Ixesha lokuposa: Oct-15-2025