Intsimbi yemanganese ephezuluivelele ngenxa yokungahambelani kwayo ukunxiba kunye nokuqina, iyenza ibe yinxalenye ebalulekileyo kwiAmacandelo omatshini wokutyumza. Esi sixhobo sinokunyamezela iimeko ezinzima, eziphakamisa ukusebenza kakuhle kwicandelo lezemigodi. Ngokucacileyo, iinkampani zonga kakhulu ngentsimbi ephezulu yemanganese, ngakumbi xa zisebenzisaIsando seNsimbi yeManganesekwimisebenzi yabo. Umzekelo, banokufikelela kugcino lonyaka lweI-3,2 yezigidi zeerandikwiindidi ezahlukeneyo zeendleko. Oku kuquka i-1.95 yezigidi zeerandi ezisindisiweyo ekunciphiseni ixesha lokuphumla elingacwangciswanga, ukuphucula ukufumaneka kwezixhobo ukusuka kwi-76.5% ukuya kwi-91.2%. Ukongeza, iindleko zokulungisa okungxamisekileyo zehla nge-680,000 yeedola ngonyaka ngenxa yokufunyanwa kwengxaki kwangoko kunye nokulungiswa okucwangcisiweyo, ngakumbi xa uqasha.Ipleyiti yokunxiba yeManganeseukuqina okongeziweyo. Ngaphezu koko, iyasebenzaUkwenza intsimbi yeManganeseivumela ukwenziwa okuchanekileyo kwamacandelo, ukomeleza ngakumbi ukusebenza kunye nokuphila ixesha elide koomatshini kwiindawo ezibango.

Izinto eziphambili zokuThatha

- Intsimbi yemanganese ephezuluinika ukuxhathisa okungafaniyo kunye nokuqina, okwenza kube yinto ebalulekileyo kwizixhobo zemigodi.

- Ukusebenzisa intsimbi ephezulu yemanganese kunokonga iinkampani ukuya kuthi ga kwi-3.2 yezigidi zeedola ngonyaka ngokunciphisa ixesha lokuphumla kunye neendleko zokulungisa.

- Ikhono lokuqina lomsebenzi wentsimbi ephezulu ye-manganese yandisa ubunzima bayo phantsi kwempembelelo, iphakamisa ukuqina kwayo kwiimeko ezinzima.

- Amacandelo entsimbi ye-manganese ephezulu anokuhlala ixesha elide kunezinye iindlela, ezikhokelela ekugcinweni okuphantsi kunye neendleko zokutshintsha.

- Utyalo-mali kwintsimbi ephezulu yemanganese kuphucula ukusebenza kakuhle,ukunciphisa ixesha lokuphumlaukuya kuthi ga kwi-30% kunye nokwandisa imveliso.

IiPropati eziZodwa zeNtsimbi yeManganese ePhezulu

Ukubunjwa kunye neSakhiwo

Intsimbi yemanganese ephezulu, edla ngokubizwa ngokuba yintsimbi yeHadfield, iqulethe umxube oyingqayizivele wezinto ezinegalelo kwiimpawu zayo ezikhethekileyo. Ubume bekhemikhali obuqhelekileyo bentsimbi ephezulu yemanganese esetyenziswa kwizicelo zokutyumza imigodi ibandakanya:

| IBanga | C (%) | Mnu (%) | P (%) | S (%) | Cr (%) | NONE |

|---|---|---|---|---|---|---|

| I-GX120Mn13 | 1.05-1.15 | 11-14 | Max. 0.06 | Max. 0.045 | - | - |

| I-GX120MnCr13-2 | 1.05-1.35 | 11-14 | Max. 0.06 | Max. 0.045 | 1.5-2.5 | - |

| I-GX120Mn18 | 1.05-1.35 | 16-19 | Max. 0.06 | Max. 0.045 | - | - |

| I-GX120MnCr18-2 | 1.05-1.35 | 16-19 | Max. 0.06 | Max. 0.045 | 1.5-2.5 | - |

| I-GX120MnNi13-3 | 1.05-1.35 | 11-14 | Max. 0.06 | Max. 0.045 | - | 3-4 |

| I-GX120MnMo13-2 | 1.05-1.35 | 11-14 | Max. 0.06 | Max. 0.045 | - | 1.8-2.1 |

Amacandelo aphambili ensimbi ephezulu yemanganese abandakanya i-manganese, ikhabhoni, kunye nentsimbi.Umxholo weManganese uqhelekile ukusuka kwi-11% ukuya kwi-14%, ngoxa ikhabhoni iyahluka ngokwebakala. Olu qulunqo oluthile luphumela kwi-microstructure eyenza ukuxhathisa ukunxiba kunye nokuqina.

I-microstructure yensimbi ephezulu yemanganese idlala indima ebalulekileyo ekusebenzeni kwayo. Ibonisa i-heterogeneous structure kunye ne-pearlite ecocekileyo kunye ne-carbides. Eli lungiselelokwandisa ukunganyangeki kwe-abrasion malunga ne-16.4%. Izinto eziphathekayo nazo zibonisa ukuqina okuphezulu kunye ne-ductility, okwenza ukuba ifaneleke kwizicelo ezifuna ukuchasana nempembelelo kunye nokugqoka i-abrasive.

Iimpawu zokuqinisa umsebenzi

Enye yezinto ezibalaseleyo zentsimbi yemanganese iyamangalisaukusebenza nzima amandla. Xa iphantsi kwempembelelo, izinto eziphathekayo ziba nokuguqulwa okwandisa kakhulu ubunzima bayo. Le nto yenzeka ngenxa yokubunjwa kwe-ε-martensite kunye namawele omatshini ngaphakathi kwe-matrix yensimbi.

Le theyibhile ilandelayo ibonisa ukonyuka kokuqina okuqatshelwe kumabanga ahlukeneyo entsimbi ephezulu yemanganese phantsi kweemeko zempembelelo:

| Izinto eziphathekayo | Ukuqina kweMatrix (HV) | Ubunzima bomphezulu ongaphantsi komhlaba (HV) | Ukunyuka kokuqina (HV) | Indlela yokuqinisa |

|---|---|---|---|---|

| Mn13 | 240.2 | 670.1 | 429.9 | Ukwenziwa kwe-ε-martensite kunye namawele omatshini |

| Mn13-2 | 256.6 | 638.2 | 381.6 | Ukwenziwa kwe-ε-martensite kunye namawele omatshini |

| Mn18-2 | 266.5 | 713.1 | 446.6 | Ukwenziwa kwe-ε-martensite kunye namawele omatshini |

Olu phawu lokuqina lomsebenzi luvumela intsimbi ephezulu yemanganese ukuba ifunxe amandla abalulekileyo ngexesha lokusebenza. Ngenxa yoko, inokumelana nemithwalo yempembelelo ephezulu ngaphandle kokuqhekeka. Le propati yenza ukuba kubaluleke kakhulu kwizicelo zemigodi, apho izixhobo zijongene neemeko ezinzima.

Xa kuthelekiswa nezinye izixhobo zemigodi ezisetyenziswa ngokuqhelekileyo, intsimbi ephezulu yemanganese ibonisa ubuchule obuphezulu bokuqina. Nangona ingabonisa amandla emveliso ephantsi phantsi komthwalo ophakathi okanye ophantsi, ukusebenza kwayo phantsi kweemeko zempembelelo ephezulu ayifani. Le ndibaniselwano ekhethekileyo yeepropati iqinisekisa ukuba intsimbi ephezulu ye-manganese ihlala ikhethwayo kwishishini lemigodi.

Izinto eziluncedo zeNtsimbi yeManganese ePhakamileyo ngaphezu kweMpahla ezizezinye

Intsimbi yemanganese ephezulu ibonelela ngeenzuzo ezibalulekileyo ngaphezu kwezinto ezizezinye kwizicelo zokutyumza imigodi. Iimpawu zayo ezizodwa zinegaleloukomelela okongeziweyokunye nokusebenza kakuhle kweendleko, okwenza kube yinto ekhethwayo kwimisebenzi emininzi yemigodi.

Ukuqina kunye Nobomi obude

Ukuqina yinto ebalulekileyo kwizixhobo zemigodi. Amacandelo aphezulu entsimbi yemanganese abonisa aubomi benkonzo obudekunezinye izinto, ngakumbi phantsi kweemeko eziqhelekileyo zokusebenza. Umzekelo, amanqanaba aphezulu entsimbi yemanganese, anje nge-Mn22, abonisa ukunxitywa okukhethekileyo kunye nokumelana nempembelelo. Ezi liners zingahlala phakathi250 ukuya 500 iiyurekwiimeko eziqhumayo, ngokuphawulekayo ngaphandle kwentsimbi eqhelekileyo yemanganese.

Ngokuthelekisa, amacandelo ensimbi ye-alloy anokuhlala ngaphezuluamaxesha amathathu ubudekunentsimbi ephezulu yemanganese phantsi kweemeko ezifanayo zokusebenza. Iimvavanyo zaselabhorethri ziqinisekisa ukuba iipleyiti zentsimbi zentsimbi zixhathisa ukunxiba ngcono, ngakumbi kwiindawo ezirhabaxa. Le theyibhile ilandelayo ishwankathela iimpawu zokuqina kwentsimbi ephezulu yemanganese ngokuchasene nentsimbi yealloy:

| Ipropati | Intsimbi yeManganese ephezulu | Intsimbi yentsimbi |

|---|---|---|

| Nxiba ukuxhathisa | Ithanda ukunxiba ngokukhawuleza kwiimeko ezithile | Ixhathisa ukunxiba ngcono, ihlala ixesha elide |

| Ukuchasa impembelelo | Ukuchasana kwempembelelo elungileyo | Ukuchasana kwempembelelo ephakathi |

| Ukuqina | Unokusebenza-nzima kodwa unciphise ubunzima obupheleleyo | Ukuqina okuphezulu (HRC 48-51) |

| Ukuqina | Ngokuqhelekileyo ayinaxesha elide kunentsimbi ye-alloy | Inokuhlala ixesha eliphindwe kathathu |

| Ukuguqulwa okunokwenzeka | Inokuguqulwa ngechromium/molybdenum | Ayilungiswanga ngokuqhelekileyo |

Ubunzima bokusebenza bentsimbi ephezulu ye-manganese buvumela ukuba ithathe amandla abalulekileyo ngexesha lokusebenza. Le propati iphakamisa ukuqina kwayo, okwenza ukuba ifaneleke kwizicelo ezinempembelelo ephezulu kwimigodi.

Iindleko-Ukusebenza

Ukusebenza kwexabiso lolunye uncedo olubalulekileyo lwentsimbi yemanganese ephezulu. Nangona utyalo-mali lokuqala lunokuba phezulu kunezinye iindlela, ugcino lwexesha elide luhlala luzodlula ezi ndleko. Amacandelo aphezulu entsimbi yemanganese abonelela ngokubanzi ubomi benkonzo obandisiweyo ngokuthelekiswa nezinye izinto. Ubomi obude buguqulela ekuncitshisweni kwamaxesha okubuyisela kunye neendleko eziphantsi zolondolozo.

Ngaphezu koko, ukusetyenziswa kwentsimbi ephezulu yemanganese kunokukhokelela ekongeni kakhulu kwiindleko zokusebenza. Iinkampani zinokunciphisa ixesha lokuphumla kunye neendleko zokulungisa, ezinegalelo ekusebenzeni kakuhle ngokubanzi. Ngokomzekelo, iinxalenye zentsimbi ye-chrome ephezulu inokuhlala ixesha eliphindwe kathathu ukuya kane kuneepleyiti zentsimbi ze-manganese eziqhelekileyo. Olu bomi bandisiweyo bunciphisa imfuno yokutshintshwa rhoqo, ekugqibeleni kukhokelela kwiindleko eziphantsi zizonke.

Ukusetyenziswa kweNtsimbi yeManganese ePhezulu kwiMigodi yokuCindezelwa

IiCrusher Liners

Intsimbi yemanganese ephezuluidlala indima ebalulekileyo ekuvelisweni kweelitha zokutyumza. Ezi liner zizinto ezibalulekileyo kwizinto ezahlukeneyoamashishini anxiba kakhulu, kuquka ukwembiwa kweekwari, ezemigodi, ukugrumba, kunye necandelo lamalahle. Zimelana nokukhuhlana okukhulu kwezinto kunye neempembelelo ezityumzayo, ziqinisekisa ukusebenza okuzinzileyo kwezityuli. Ukuxhathisa okuphezulu kokunxiba kunye nobomi benkonzo eyandisiweyo yentsimbi ephezulu yemanganese yenza ukuba ilungele usetyenziso olunzima.

Le theyibhile ilandelayo iqaqambisa uphuculo lokusebenza oluphawulweyo xa kusetyenziswa intsimbi ephezulu yemanganese kwiilitha zokutyumza:

| UkuPhuculwa koMsebenzi | Inkcazo |

|---|---|

| UkuGqiba okugqwesileyo kokumelana | Umboniso weentsimbi zentsimbi eziphakamileyo zemanganeseuxhathiso olukhethekileyo lokunxiba, ukwandisa ubomi besixhobo. |

| Iipropati zokuziQinisa | I-Liners ikwandisa ubunzima bomhlaba ngokuhamba kwexesha, ukuphucula ukunyanzeliswa kokugqoka kunye nokusebenza kakuhle. |

| I-Crusher eFanelekileyo | Ubulukhuni obuphezulu bukhokelela ekucutheni okusebenzayo, ukunciphisa ukulahleka kwamandla kunye nokuphucula umthamo wokuvelisa. |

| UkuNcitshiswa kweZixhobo zokuSebenza rhoqo | Ukunyuka kokuqina komphezulu kubangela ukuguga okucothayo, ukunciphisa isidingo sokutshintshwa rhoqo. |

| Uphuculo lweMveliso eFanelekileyo | Ubomi obude benkonzo kunye nexesha elincitshisiweyo lokuphumla liphucula ukuqhubeka komgca wemveliso kunye nemveliso yonke. |

| Ukuchasa okunamandla | Ii-liners zimelana nempembelelo enkulu, zigcina ukusebenza okuzinzile kunye nokunciphisa iindleko zokugcinwa. |

| Iindleko zokuSebenza eziNcitshisiweyo | Ukugcinwa kancinci rhoqo kunye nokutshintshwa kuthoba iindleko zokusebenza kunye nokuphucula izibonelelo zoqoqosho. |

Imihlathi kunye neCone Crushers

Intsimbi yemanganese ephezulu kakhuluiphucula ukusebenza kwemihlathi kunye nezityumli zekhowuni. Malunga ne-70% yeimihlathi kunye nezityuli zekhowunikwishishini lemigodi sebenzisa amacandelo entsimbi yemanganese ephezulu. Ezi zinto zibonelelaUkuqina okungaqhelekanga kunye nokuqina, kubalulekile ukufunxa ukothuka kwiindawo ezinoxinzelelo oluphezulu.

Iimpawu ezikhethekileyo zentsimbi ephezulu ye-manganese zivumela ukuba zifunxe kwaye zichithe amandla othusayo ngokufanelekileyo. Oku kuthintela iintanda okanye iifractures, nto leyo ibalulekileyo ekulungiseni izinto eziqinileyo. La manqaku alandelayo ashwankathela izibonelelo zentsimbi ephezulu yemanganese kumhlathi kunye nezityumli zekhowuni:

- Intsimbi ye-Manganese isebenza-nzima kunye nempembelelo nganye, inyusa ukuchasana kwayo nokuxhatshazwa.

- Igcina ukuqina okuphezulu, ifunxa amandla amakhulu empembelelo ngaphandle kokuqhekeka.

- Olu kudibanisa luvumela ukuba luqhube kakuhle kwiimeko ezinqabileyo kunye neempembelelo eziphezulu.

Ngokunciphisa imfuno yokutshintshwa kwenxalenye rhoqo, intsimbi ephezulu yemanganese inciphisa ixesha lokuphumla kwaye yongeza imveliso iyonke. Ixabiso layo elisebenzayo livela kwixesha elide lokuphila lamacandelo, elikhokelela kwiimfuno eziphantsi zokugcinwa.

Impembelelo yeNtsimbi yeManganese ePhezulu kwiMsebenzi neMveliso

Ixesha lokuphumla elincitshisiweyo

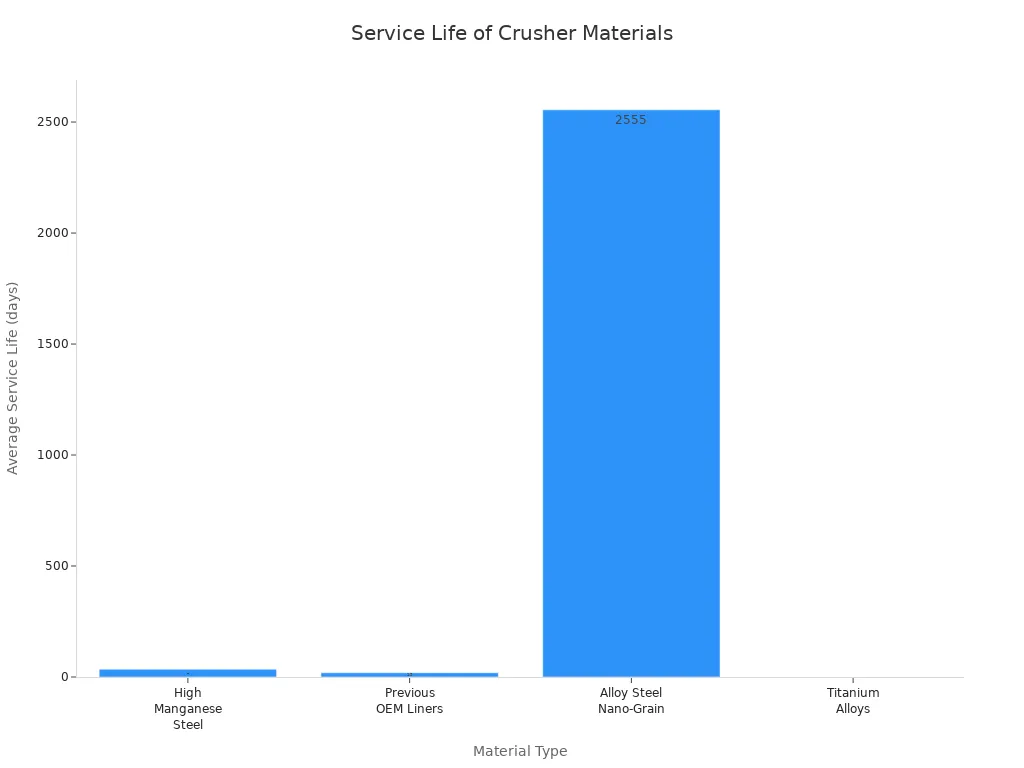

Intsimbi yemanganese ephezulu inciphisa kakhulu ixesha lokuphumla kwimisebenzi yemigodi. Ukuqina kwayo kunyenxiba ukumelanakukhokelela kubomi benkonzo obude kumacandelo. Umzekelo, iintambo zentsimbi zemanganese eziphezulu zinokuhlala umndilili weIintsuku ezingama-35, xa kuthelekiswa neentsuku ezili-19 kuphela ze-OEM zangaphambili. Olu phuculo luvumela iinkampani zemigodi ukuba zigcine imisebenzi eqhubekayo ngaphandle kokuphazamiseka rhoqo ekutshintsheni inxalenye.

| Uhlobo lwezinto eziphathekayo | Ubomi Benkonzo obuqhelekileyo | Amanqaku |

|---|---|---|

| Intsimbi yeManganese ephezulu (Xtralloy) | Iintsuku ezingama-35 | Uphuculo olubalulekileyo kwiilayini ze-OEM zangaphambili. |

| Ngaphambili OEM Liners | Iintsuku ezili-19 | Ubomi benkonzo ephantsi xa kuthelekiswa neXtralloy. |

| Intsimbi yeAlloy eneNano-Grain Forging | 5-7 iminyaka | Ubomi obude kunentsimbi ephezulu yemanganese. |

| I-Titanium Alloys | 7-9 iminyaka | Ubomi obuphezulu xa kuthelekiswa nentsimbi ephezulu yemanganese. |

Ubomi obandisiweyo bamacandelo entsimbi ephezulu yemanganese bukhokelela ekuvalweni kogcino okumbalwa. Abaxhasi banike ingxelo yokwehliswa kwexesha lolondolozo ukuya kuthi ga30%emva kokutshintshela kwiindawo eziphezulu zentsimbi ye-manganese. Oku kuncitshiswa akuphuculi imveliso kuphela kodwa kunegalelo kugcino lweendleko ezibalulekileyo.

Iimetriki zokuSebenza eziphuculweyo

Intsimbi yemanganese ephezulu yongeza iimethrikhi ezininzi zokusebenza kwisixhobo sokutyumza imigodi. Iimpawu zayo ezizodwa ziphucula ukuxhathisa ukunxiba, ukuqina, kunye nokuqina ngokubanzi. Ngenxa yoko, amava okusebenza kwemigodi:

- Nxiba ukuxhathisa: Intsimbi ye-manganese ephezulu iba nzima ngokuhamba kwexesha xa ibonakaliswe kwi-friction, iyenza ibe yinto efanelekileyo kwizicelo apho ukunxiba kuyinkxalabo.

- Ukuqina: Ukuqina kwemathiriyeli kukhulisa ukukwazi kwayo ukumelana neempembelelo kunye namandla abrasive, okubalulekileyo kwimo engqongileyo yemigodi.

- Ukuqina: Ukuzinza ngokubanzi kuphuculwe, okukhokelela ekunciphiseni ixesha lokunciphisa kunye neendleko eziphantsi zokugcinwa.

Imodeli yoqikelelo lobomi bonke beepleyiti ezityumzayo ibonisa ingcambu ephantsi ithetha impazamo yesikwere (RMSE) ye0.0614 iiyure. Oku kuchaneka kubonisa ukuba intsimbi ephezulu ye-manganese iphakamisa kakhulu imveliso, kunye nexesha lokuphila ukusuka kwii-746 ukuya kwii-6902 iiyure. Iinkampani ezigxile kumacandelo asemgangathweni zifumana ukuphuculwa kwemveliso ukuya kuthi ga kwi-20%.

Ngotyalo-mali kwizinto eziphezulu zentsimbi ye-manganese, imisebenzi yezemigodi inokufikelela kwiimetriki zokusebenza ezingcono kunye nokusebenza kakuhle.

Intsimbi yemanganese ephezuluiipropati ziyenza ibaluleke kakhulu kwizicelo zokucolwa kwemigodi. Ukubunjwa kwayo okukhethekileyo kwandisa ukuqina, ukuxhathisa ukunxiba, kunye nokuqina. Esi sixhobo siphucula kakhulu imveliso kunye nokugcinwa kweendleko zemisebenzi yemigodi. Iinzuzo eziphambili ziquka:

- Amathuba olondolozo awandisiweyo ngo30–40%

- Ukunciphisa ukuphindaphinda kwenxalenye yokutshintshwa

- Iindleko zokusebenza eziphantsi

Imfuno yentsimbi yemanganese ephezulukuqikelelwa ukunyukangenxa yokusebenza kwayo okungenakuthelekiswa nanto kwiimeko ezinzima. Njengoko ubugcisa bezemigodi buguquka, ukusetyenziswa okuqhubekayo kwentsimbi yemanganese ephezulu kuhlala kubalulekile ekusebenzeni okusebenzayo.

| Ipropati/Umsebenzi | Inkcazo |

|---|---|

| I-Deoxidising Agent | Isusa ioksijini kunye nesulfure ukungcola kwintsimbi etyhidiweyo, ukuphucula amandla kunye nokuqina. |

| Ingxubevange yokuqinisa | Yongeza ukuqina, ukuqina, kunye nokumelana nokunxiba ngokwenza iikhompawundi ezizinzileyo kunye nekhabhoni. |

| I-Hardenability Booster | Ukwandisa ukuqina, ukwenza insimbi ifaneleke kwizicelo zesakhiwo phantsi koxinzelelo. |

| Intsimbi yeManganese ephezulu | Iqulethe i-12–14% yemanganese, eyaziwa ngeempawu ezikhethekileyo zokuqinisa umsebenzi, ilungele ukusebenza kwemigodi. |

FAQ

Yintoni intsimbi yemanganese ephezulu?

Intsimbi ephezulu ye-manganese yi-alloy equkethe i-11-14% ye-manganese. Iyaziwa ngokuqina kwayo okungaqhelekanga kunye nokumelana nokunxiba, okwenza ukuba ilungele izicelo zemigodi.

Isebenza njani intsimbi ephezulu yemanganese?

Umsebenzi wentsimbi yemanganese ephezulu uba nzima xa uphantsi kwempembelelo. Le nkqubo ikwandisa ubulukhuni bayo, ivumela ukuba ithathe amandla amaninzi kwaye ixhathise ukunxiba.

Zeziphi izicelo eziphambili zentsimbi yemanganese ephezulu emigodini?

Intsimbi ephezulu yemanganese isetyenziswa ikakhulu kwiilitha zokutyumza,izityumzi zemihlathi, kunye nezityuli zekhowuni. Ukomelela kwayo kuyenza ifaneleke kwiindawo ezinefuthe eliphezulu kunye ne-abrasive.

Kutheni le nto intsimbi ephezulu yemanganese ingabizi kakhulu?

Nangona intsimbi ye-manganese ephezulu inokuba neendleko eziphezulu zokuqala, ubomi bayo benkonzo ende kunyeiimfuno ezincitshisiweyo zokulondolozwakukhokelela kulondolozo olubalulekileyo ekuhambeni kwexesha.

Injani intsimbi yemanganese ephezulu xa ithelekiswa nezinye izinto?

Intsimbi yemanganese ephezulu inika ukumelana nokunxiba okuphezulu kunye nokuqina xa kuthelekiswa nezinye izinto ezifana nentsimbi yealloy. Oku kwenza kube lukhetho olukhethwayo kwizicelo ezifunwayo zemigodi.

Ixesha lokuposa: Oct-24-2025