Inkcazo

Ukuvelisa iimveliso ezikumgangatho ophezulu ngexabiso eliphantsi kunye nokusebenza okuphezulu kunye nokuthembeka, kufuneka ukhethe iindawo zokunxiba ezilungiselelwe isicelo sakho sokutyumza. Imiba ephambili ekufuneka iqwalaselwe ngolu hlobo lulandelayo:

1. Uhlobo lwamatye okanye iiminerali eziza kutyunyuzwa.

2. Ubungakanani besuntswana lezinto eziphathekayo, umxholo wokufuma kunye nebakala lobulukhuni be-Mohs.

3. Izinto kunye nobomi bemivalo yokuvuthela esetyenziswe ngaphambili.

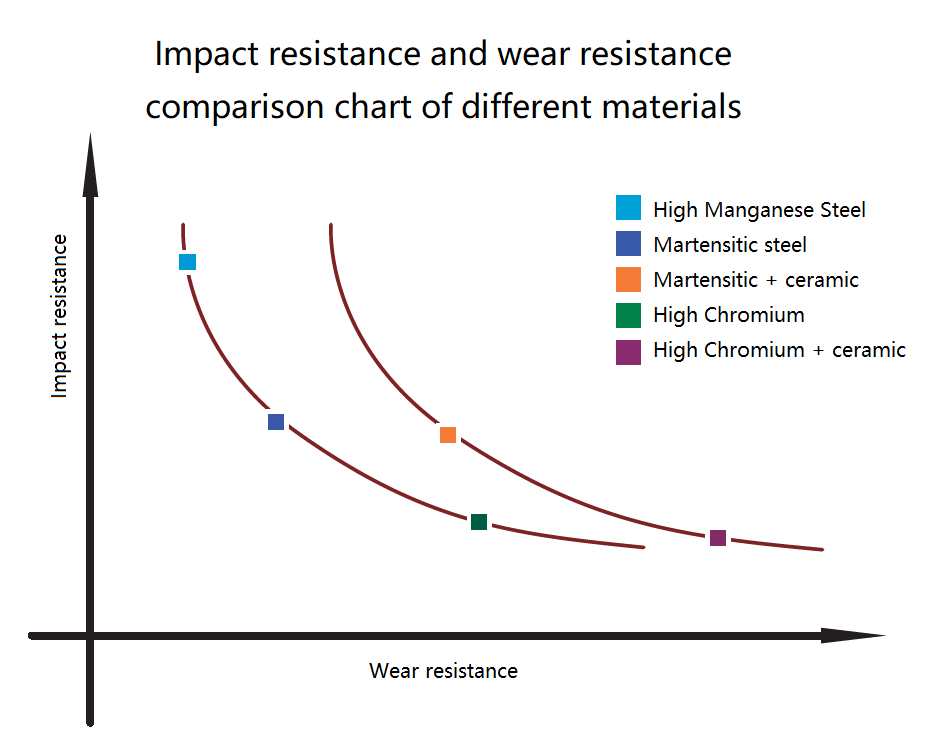

Ngokubanzi, ukuxhathisa ukunxiba (okanye ubunzima) bezinto ezixhonywe eludongeni zentsimbi ziya kunciphisa ukuxhathisa kwayo (okanye ukuqina). Indlela yokufakela udongwe kwizinto ze-matrix zetsimbi inokunyusa kakhulu ukuxhatshazwa kwayo ngaphandle kokuchaphazela ukuchasana kwayo kwempembelelo.

Intsimbi yeManganese ephezulu

Intsimbi ephezulu yemanganese yinto enganxibiyo enembali ende kwaye isetyenziswe ngokubanzi kwizityuli zempembelelo. Intsimbi yemanganese ephezulu inokumelana neempembelelo ezibalaseleyo. Ukuxhatshazwa kokugqoka ngokuqhelekileyo kuhambelana noxinzelelo kunye nefuthe kumphezulu walo. Xa impembelelo enkulu isetyenzisiwe, ulwakhiwo lwe-austenite kumphezulu lunokwenziwa lukhuni lube yi-HRC50 okanye ngaphezulu.

Izando zentsimbi yentsimbi yemanganese ephezulu zicetyiswa ngokubanzi kuphela ukutyunyuzwa okuphambili ngemathiriyeli yobungakanani bamasuntswana okutya kunye nobunzima obuphantsi.

Ukubunjwa kweekhemikhali zentsimbi ephezulu yemanganese

| Izinto eziphathekayo | Ukuqulunqwa kwemichiza | Ipropati yoMsebenzi | ||||

| Mn% | Cr% | C% | Si% | Ak/cm | HB | |

| Mn14 | 12-14 | 1.7-2.2 | 1.15-1.25 | 0.3-0.6 | > 140 | 180-220 |

| Mn15 | 14-16 | 1.7-2.2 | 1.15-1.30 | 0.3-0.6 | > 140 | 180-220 |

| Mn18 | 16-19 | 1.8-2.5 | 1.15-1.30 | 0.3-0.8 | > 140 | 190-240 |

| Mn22 | 20-22 | 1.8-2.5 | 1.10-1.40 | 0.3-0.8 | > 140 | 190-240 |

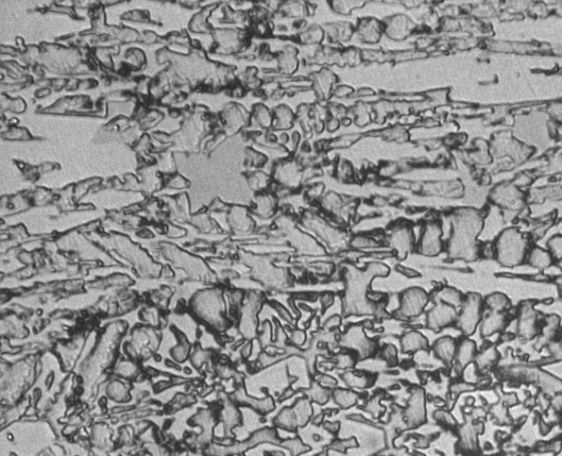

I-Microstructure yentsimbi ephezulu yemanganese

Intsimbi yeMartensitic

Isakhiwo seMartensite senziwe ngokupholisa ngokukhawuleza kwentsimbi yekhabhoni egcwele ngokupheleleyo. Iiathom zekhabhoni zinokusasazeka ngaphandle kwe-martensite kuphela kwinkqubo yokupholisa ngokukhawuleza emva konyango lobushushu. Intsimbi yeMartensitic inobunzima obuphezulu kunentsimbi ye-manganese ephezulu, kodwa ukuchasana kwayo nempembelelo kuye kwancitshiswa ngokufanayo. Ubunzima bentsimbi ye-martensitic buphakathi kwe-HRC46-56. Ngokusekwe kwezi propati, ibha yentsimbi ye-martensitic iyacetyiswa ngokubanzi ukutyumza izicelo apho impembelelo ephantsi kakhulu kodwa ukuxhathisa okuphezulu kuyafuneka.

I-Microstructure yentsimbi ye-martensitic

Intsimbi eMhlophe yeChromium ephezulu

Kwintsimbi emhlophe yechromium ephezulu, ikhabhoni idityaniswa nechromium ngendlela yechromium carbide. Intsimbi emhlophe yechromium ephezulu inokumelana nokunxiba okugqwesileyo. Emva kokunyangwa kobushushu, ubulukhuni bayo bunokufikelela kwi-60-64HRC, kodwa ukuchasana kwempembelelo yayo kuyancitshiswa ngokufanayo. Xa kuthelekiswa nentsimbi ephezulu yemanganese kunye nentsimbi ye-martensitic, intsimbi ephezulu yechromium inowona mandla uxhathisayo wokunxiba, kodwa ukuxhathisa kwayo kolona luphantsi.

Kwintsimbi emhlophe yechromium ephezulu, ikhabhoni idityaniswa nechromium ngendlela yechromium carbide. Intsimbi emhlophe yechromium ephezulu inokumelana nokunxiba okugqwesileyo. Emva kokunyangwa kobushushu, ubulukhuni bayo bunokufikelela kwi-60-64HRC, kodwa ukuchasana kwempembelelo yayo kuyancitshiswa ngokufanayo. Xa kuthelekiswa nentsimbi ephezulu yemanganese kunye nentsimbi ye-martensitic, intsimbi ephezulu yechromium inowona mandla uxhathisayo wokunxiba, kodwa ukuxhathisa kwayo kolona luphantsi.

Ukwakhiwa kweekhemikhali zentsimbi emhlophe yechromium ephezulu

| I-ASTM A532 | Inkcazo | C | Mn | Si | Ni | Cr | Mo | |

| I | A | Ni-Cr-Hc | 2.8-3.6 | 2.0 Ubuninzi | 0.8 Ubuninzi | 3.3-5.0 | 1.4-4.0 | 1.0 Ubuninzi |

| I | B | Ni-Cr-Lc | 2.4-3.0 | 2.0 Ubuninzi | 0.8 Ubuninzi | 3.3-5.0 | 1.4-4.0 | 1.0 Ubuninzi |

| I | C | I-Ni-Cr-GB | 2.5-3.7 | 2.0 Ubuninzi | 0.8 Ubuninzi | 4.0 Ubuninzi | 1.0-2.5 | 1.0 Ubuninzi |

| I | D | Ni-HiCr | 2.5-3.6 | 2.0 Ubuninzi | 2.0 Ubuninzi | 4.5-7.0 | 7.0-11.0 | 1.5 Ubuninzi |

| II | A | 12Kr | 2.0-3.3 | 2.0 Ubuninzi | 1.5 Ubuninzi | 0.40-0.60 | 11.0-14.0 | 3.0 Ubuninzi |

| II | B | 15CrMo | 2.0-3.3 | 2.0 Ubuninzi | 1.5 Ubuninzi | 0.80-1.20 | 14.0-18.0 | 3.0 Ubuninzi |

| II | D | 20CrMo | 2.8-3.3 | 2.0 Ubuninzi | 1.0-2.2 | 0.80-1.20 | 18.0-23.0 | 3.0 Ubuninzi |

| III | A | 25Kr | 2.8-3.3 | 2.0 Ubuninzi | 1.5 Ubuninzi | 0.40-0.60 | 23.0-30.0 | 3.0 Ubuninzi |

IMicrostructure ye-High Chromium White iron

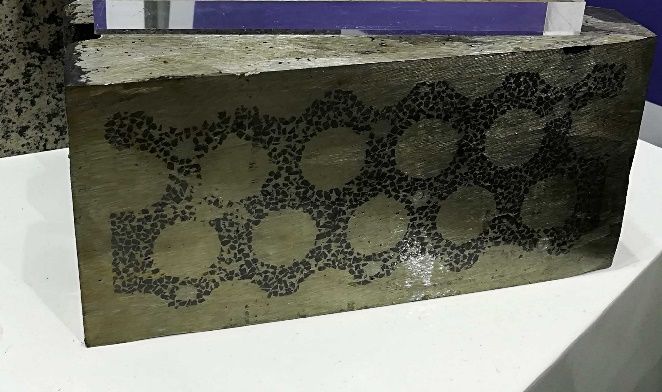

I-Ceramic-Metal Composite Material (CMC)

I-CMC yimathiriyeli engagugiyo edibanisa ukuqina okuhle kwezinto zetsimbi (intsimbi ye-martensitic okanye intsimbi ephezulu yechromium) kunye nobunzima obuphezulu kakhulu bekeramics kushishino. Iincinci zeCeramic zobukhulu obuthile ziphathwa ngokukodwa ukwenza i-porous body of particles ceramic. Isinyithi esityhidiweyo singena ngokupheleleyo kwi-interstics yesakhiwo se-ceramic ngexesha lokuphosa kwaye idibanisa kakuhle kunye neengqungquthela zobumba.

Olu luyilo lunokuphucula ngokufanelekileyo ukusebenza okuchasene nokunxiba kobuso obusebenzayo; ngelo xesha, umzimba oyintloko webha yokuvuthela okanye ihamile isenziwe ngentsimbi ukuqinisekisa ukusebenza kwayo ngokukhuselekileyo, ukusombulula ngokufanelekileyo ukuphikisana phakathi kokumelana nokunxiba kunye nokuchasana kwempembelelo, kwaye inokulungiswa kwiimeko ezahlukeneyo zokusebenza. Ivula intsimi entsha yokukhethwa kweendawo eziphezulu zokunxiba kuninzi lwabasebenzisi, kunye nokudala inzuzo engcono yezoqoqosho.

a.Martensitic Steel + Ceramic

Xa kuthelekiswa nebar eqhelekileyo ye-martensitic blowhammer, isando se-martensitic seceramic sinobunzima obuphezulu kumphezulu wokunxiba, kodwa ukuxhathisa kwesando sokubetha akuyi kuncipha. Kwiimeko zokusebenza, ibar yokuvuthela ye-martensitic ceramic ingaba yindawo efanelekileyo yesicelo kwaye idla ngokufumana phantse amaxesha ama-2 okanye ubomi obude benkonzo.

b.I-Iron eMhlophe yeChromium ePhezulu + neCeramic

Nangona intsimbi yentsimbi ephezulu yechromium sele inokumelana nokunxiba okuphezulu, xa kutyunyuzwa izixhobo ezinobunzima obuphezulu kakhulu, njengegranite, imivalo yokuvuthela ekwaziyo ukunxitywa iqhele ukusetyenziselwa ukwandisa ubomi babo bokusebenza. Kule meko, intsimbi ephezulu ye-chromium ene-ceramic blowu bar efakiweyo isisombululo esingcono. Ngenxa yokufakela i-ceramics, ukuqina komphezulu we-hammer yokuvuthela kwandiswa ngakumbi, kwaye ukuxhathisa kwayo kuphuculwe kakhulu, ngokuqhelekileyo amaxesha angama-2 okanye ubomi obude benkonzo kunentsimbi eqhelekileyo ephezulu yechromium emhlophe.

Izinto eziluncedo zeCeramic-Metal Composite Material (CMC)

(1) Iqinile kodwa ingabi brittle, iqinile kwaye ingagugi, ifikelela kwibhalansi emibini yokumelana nokunxiba kunye nokuqina okuphezulu;

(2) Ubunzima be-ceramic yi-2100HV, kwaye ukuxhathisa ukunxiba kunokufikelela kwi-3 ukuya kwamaxesha ama-4 kwizinto eziqhelekileyo ze-alloy;

(3) Uyilo lwesikimu somntu, umgca wokunxiba onengqiqo ngakumbi;

(4) Ubomi benkonzo ende kunye neenzuzo eziphezulu zoqoqosho.

IParameter yeMveliso

| Uphawu lomatshini | Imodeli yomatshini |

| Metso | I-LT-NP 1007 |

| I-LT-NP 1110 | |

| I-LT-NP 1213 | |

| I-LT-NP 1315/1415 | |

| I-LT-NP 1520/1620 | |

| Hazemag | 1022 HAZ791-2 HAZ879 HAZ790 HAZ893 HAZ975 HAZ817 |

| 1313 HAZ796 HAZ857 HAZ832 HAZ879 HAZ764 HAZ1073 | |

| 1320 HAZ1025 HAZ804 HAZ789 HAZ878 HAZ800A HAZ1077 | |

| 1515 HAZ814 HAZ868 HAZ1085 HAZ866 HAZ850 HAZ804 | |

| 791 HAZ565 HAZ667 HAZ1023 HAZ811 HAZ793 HAZ1096 | |

| 789 HAZ815 HAZ814 HAZ764 HAZ810 HAZ797 HAZ1022 | |

| Sandvik | I-QI341 (QI240) |

| I-QI441(QI440) | |

| I-QI340 (I-C13) | |

| CI124 | |

| CI224 | |

| Kleemann | MR110 EVO |

| MR130 EVO | |

| MR100Z | |

| MR122Z | |

| Terex Pegson | XH250 (CR004-012-001) |

| XH320-entsha | |

| XH320-ndala | |

| 1412 (XH500) | |

| 428 itrektara 4242 (300 phezulu) | |

| Isikrini samandla | Trackpactor 320 |

| Terex Finlay | I-100 |

| I-110 | |

| I-120 | |

| I-130 | |

| I-140 | |

| Rubblemaster | R60 |

| R70 | |

| R80 | |

| I-R100 | |

| I-R120 | |

| Tesab | I-RK-623 |

| I-RK-1012 | |

| Extec | C13 |

| iTelsmith | 6060 |

| Keestrack | R3 |

| R5 | |

| McCloskey | I44 |

| I54 | |

| Lippmann | 4248 |

| Ukhozi | 1400 |

| 1200 | |

| Umbethi | 907 |

| 1112/1312 -100mm | |

| 1112/1312 -120mm | |

| 1315 | |

| Kumbee | No1 |

| No2 | |

| Shanghai Shanbao | PF-1010 |

| PF-1210 | |

| PF-1214 | |

| PF-1315 | |

| SBM/Henan Liming/Shanghai Zenith | PF-1010 |

| PF-1210 | |

| PF-1214 | |

| PF-1315 | |

| PFW-1214 | |

| PFW-1315 |