Intsimbi yeManganese iguqule isinyithi kunye namashishini anzima ngamandla ayo akhethekileyo kunye nokuqina. Yafunyaniswa nguMhlekazi uRobert Hadfield ngowe-1882, le ngxubevange idibanisa intsimbi, ikhabhoni, kunye nemanganese ukwenza imathiriyeli emele yahluke kuzo zonke ezinye. Isakhono saso esisodwa sokuqina phantsi kwempembelelo yenze ukuba ibengumdlalo-wokutshintsha izixhobo, oomatshini, kunye nezicelo zokwakha.

Iimpawu ezimangalisayo zentsimbi yemanganese zisuka kwindima ebalulekileyo yemanganese ekwenzeni intsimbi. Ayipheleli nje ekupheliseni ukungcola okufana nesalfure kunye neoksijini, kodwa ikwanyusa kakhulu ubulukhuni kunye nokumelana nokunxiba. Ngokuhamba kwexesha, ukuqhubela phambili okunje ngonyango lobushushu kunye neendlela zokwenziwa kwe-cutting-edge ziye zandisa ngakumbi ukubanakhoishidi lentsimbi yemanganese, ipleyiti yentsimbi yemanganese, kwayeiintambo zentsimbi yemanganese.

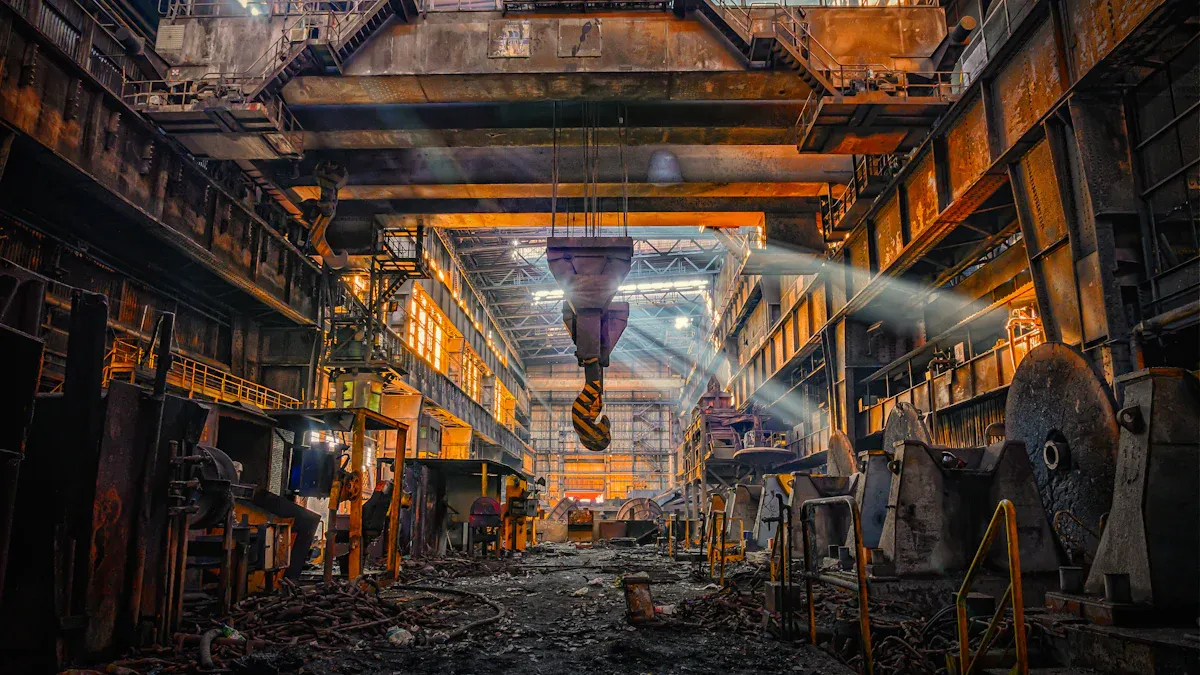

Namhlanje, intsimbi ye-manganese kunyeipleyiti yentsimbi yemanganeseukuqhubeka nokusebenza njengezinto ezisisiseko kumashishini afuna ukuchasana kwempembelelo ephezulu, kubandakanya imigodi kunye noololiwe.

Izinto eziphambili zokuThatha

- Intsimbi yeManganeseyaqanjwa nguMhlekazi uRobert Hadfield ngowe-1882.

- Yomelele kakhulu kwaye iba nzima xa ibethwa, iyenza ibe ntle kwimisebenzi enzima.

- Inkqubo ye-Bessemer yenza intsimbi ye-manganese ibe ngcono ngokususa ukungcola.

- Le nkqubo yenza ukuba intsimbi yomelele kwaye ihlale ixesha elide.

- Intsimbi yeManganese isetyenziswa kwimigodi, imizila kaloliwe, kunye nokwakha ngenxa yokoimelana nokunxiba.

- Ukuqina kwayo kunceda ukunciphisa iindleko zokulungisa kwaye kwenza izixhobo zihlale ixesha elide.

- Iindlela ezintsha zokuxuba i-alloys kunye nokwenza insimbi iphucule ukusebenza kwayo namhlanje.

- Ukurisayikilisha intsimbi yemanganese kubalulekile ekugcineni izixhobo kunye nokunceda iplanethi.

Imvelaphi yentsimbi yeManganese

Ukufunyanwa kukaMhlekazi uRobert Hadfield

Ibali lentsimbi yemanganese liqala ngoMhlekazi uRobert Hadfield, ingcali yesinyithi yaseBritani eyafumanisa into eyothusayo ngo-1882. Ngokungafaniyo nentsimbi yemveli, le mathiriyeli intsha yayinzima kwaye iqinile, iyenza ilungele usetyenziso olunempembelelo ephezulu.

Umsebenzi kaHadfield wawungenangxaki. Kwangoko, waqaphela ukuba intsimbi yemanganese ixhathisa umatshini kwaye ayinakubanjwa, nto leyo eyenza kube nzima ukusebenza nayo. Noko ke, le miqobo ayizange imthintele. Endaweni yoko, baqaqambisa ubume obubodwa be-alloy kunye namandla ayo okuguqula amashishini.

- Ukuqina kwentsimbi yeManganese kunye neempawu zokuziqinisa ziyibeka yahluke kwezinye izinto.

- Iziphumo zikaHadfield zagxininisa imanganese njengeyona nto iphambili enoxanduva kwezi mpawu zimangalisayo.

Iimvavanyo zakwangoko kunye noPhuhliso lwe-Alloy

Ukufunyaniswa kukaHadfield kubangele igagasi lemifuniselo yokucokisa ingxubevange nokuqonda ukuziphatha kwayo. Abaphandi bagxile kwindlela i-manganese edibana ngayo nezinye izinto ezifana nekhabhoni kunye nentsimbi. Ezi zifundo zangaphambili zabeka isiseko sentsimbi yemanganese esiyaziyo namhlanje.

Isenzo sangaphambili sokujongana ne-ingots ye-manganese-steel ukususela ngonyaka we-1887 ukuya phambili yayikukutshisa iingots ezishushu kakhulu kunamaqondo obushushu abhekisa kuwo uMnu. Kudala ngaphambi konyaka we-1900 amawaka amaninzi eetoni ezo zinto zenziwe zaza zasetyenziswa. Kwiphepha elalinikelwe kweli ziko ngumbhali ngo-1893, elinesihloko esithi I-Iron Alloys, kunye neNgcaciso eKhethekileyo yeManganese Steel, iinkcukacha ezipheleleyo kunye neefoto zibonisiwe ngentsimbi yemanganese eyenzelwe iiasi zikaloliwe zaza zaqengqeleka zangamatayara kaloliwe.

Njengoko abaphandi babezama, bafumene iinkcukacha ezinomdla malunga notshintsho lwesigaba se-alloy kunye ne-microstructure. Ngokomzekelo, olunye uphononongo luye lwavavanya ingxubevange ye-manganese ephakathi eyenzelwe ukwenza izinto. Iziphumo zatyhila indlela amazinga okufudumeza kunye namaxesha okufunxa aphembelele iipropathi zemathiriyeli:

| Iziphumo | Inkcazo |

|---|---|

| IiNguqu zeSigaba | Uphononongo lugxininise kwiinguqu zesigaba kwi-alloy ye-Medium-Mn, ngokukodwa i-0.19C-5.4Mn-0.87Si-1Al, eyenzelwe i-forgings. |

| Ukungangqinelani | Uphando lubonise ukungangqinelani phakathi kokulinganisa kwe-thermodynamic kunye neziphumo zovavanyo, kugxininisa imfuneko yokuqwalaselwa ngononophelo kumazinga okufudumeza, amaxesha okumanzisa, kunye ne-microstructure yokuqala. |

Olu vavanyo lwanceda ekucokiseni ukubunjwa kwentsimbi yemanganese, iyenza ithembeke ngakumbi kwaye isebenziseke ngeendlela ezininzi ekusetyenzisweni kwemizi-mveliso.

Patenting kunye nezicelo zokuqala

Umsebenzi kaHadfield uye wafikelela kuvuthondaba kulungelo lomenzi weintsimbi yemanganesengowe-1883. Ukukwazi kwe-alloy ukuba lukhuni phantsi kweempembelelo kwenze ukuba kutshintshe umdlalo kumashishini afana nemigodi kunye neendlela zikaloliwe.

Olunye usetyenziso lokuqala lwentsimbi yemanganese yayikwimizila kaloliwe kunye neeasi. Ukomelela kwayo kunye nokuxhathisa ukunxitywa kuyenze ilungele ukuphatha imithwalo enzima kunye nokukhuhlana okungaguqukiyo koololiwe. Ekuhambeni kwexesha, abavelisi baqalisa ukuyisebenzisela abanyeizixhobo ezinefuthe eliphezulukunye noomatshini, beqinisa ngakumbi indawo yabo kwimbali yoshishino.

Imveliso entsha kaHadfield ayizange ivele idale imathiriyeli entsha; kwavula umnyango wexesha elitsha kwi-metallurgy. Intsimbi yeManganese yaba luphawu lwenkqubela phambili, ingqina ukuba inzululwazi kunye neshishini zinokusebenzisana ukusombulula iingxaki zehlabathi lokwenyani.

Ukuqhubela phambili kwiTekhnoloji yeNsimbi yeManganese

Inkqubo yeBessemer kunye nendima yayo

IInkqubo yeBessemeridlale indima ebalulekileyo kuphuhliso lokuqala lwentsimbi yemanganese. Le ndlela entsha yokwenza insimbi, eyaziswa phakathi kwenkulungwane ye-19, yavumela abavelisi ukuba bavelise intsimbi ngokufanelekileyo ngokususa ukungcola okufana nekhabhoni kunye ne-silicon. Xa u-Sir Robert Hadfield ezama i-manganese ngentsimbi, inkqubo ye-Bessemer yaba sisixhobo esibalulekileyo sokucokisa i-alloy.

Ngokubandakanya i-manganese kwinkqubo, abenzi bentsimbi banokwenza izinto ezinamandla kunye nokuqina. Le nkqubo ikwanceda ekupheliseni isulfure neoksijini, eyayidla ngokuyenza buthathaka intsimbi yesintu. Le mpumelelo yabeka isiseko sokwamkelwa ngokubanzi kwentsimbi yemanganese kwizicelo zemizi-mveliso.

IiPropati zokuQinisekisa komsebenzi zicacisiwe

Enye yezona zinto zinomdla kakhulu zentsimbi ye-manganese kukukwazi ukuqina phantsi kweempembelelo. Le propati, eyaziwa ngokuba ngumsebenzi onzima, kwenzeka xa izinto zingena kwi-deformation. Njengoko umphezulu ufumana uxinzelelo, uyaqina kwaye uxhathise ngakumbi ukunxiba.

Uphononongo lubonise ukuba esi siphumo siphenjelelwa zizinto ezifana nobushushu kunye ne-microstructure yemathiriyeli. Ngokomzekelo, uphando malunga nekhabhoni ephantsi, i-high-manganese steels ibonise ukuba i-twinning yomatshini kunye neenguqu ze-martensitic ziphucula kakhulu amandla kunye ne-ductility.

| Umba | Inkcazo |

|---|---|

| Izinto eziphathekayo | Iintsimbi ezisezantsi-C eziphezulu zemanganese |

| Ubushushu bokuguqulwa | -40 °C, 20 °C, 200 °C |

| Ukuqwalaselwa | Uguqulo olunyanzeliswa kukunyanzelwa kunye nokudibanisa ngoomatshini kuphucula iipropati. |

| Iziphumo | Iqondo lobushushu lichaphazela ukuziphatha kokuqina kunye ne-microstructure evolution. |

Le propati yahlukileyo yenza intsimbi ye-manganese ifanelekele iindawo ezinempembelelo ephezulu njengemigodi kunye nokwakha.

Uphuculo kwi-Alloy Composition

Ukutyhubela iminyaka, abaphandi bayeicociwe ukwakhekayentsimbi yemanganese ukuphucula ukusebenza kwayo. Ukongezwa kwezinto ezifana ne-aluminiyam kunye ne-silicon kukhokelele kwinkqubela phambili ebalulekileyo. Ngokomzekelo, ukwandisa umxholo we-aluminium kwandisa amandla esivuno kunye nokumelana nokunxiba, nangona kunokunciphisa i-ductility.

| Ukuqulunqwa kwe-alloy | Ubushushu boNyango loBushushu | Nxiba ukuxhathisa | Iziphumo |

|---|---|---|---|

| Isilicon | 700 °C | Iphuculwe | Ukuxhathisa ukunxiba okugqwesileyo phantsi komthwalo wempembelelo ephezulu. |

| Intsimbi yeManganese ePhakathi | Ezahlukeneyo | Ihlalutyiwe | Isakhelo esidibanisa ukwakheka kunye neempawu. |

Olu lungiso lwenze intsimbi yemanganese yasebenza ngeendlela ezininzi, iqinisekisa ukuba ihlala ililitye lembombo kushishino lwangoku.

Usetyenziso lwezoShishino lweManganese Steel

IZixhobo zokwembiwa kwemigodi nezakwakwari

Intsimbi yeManganese idlala indima ebalulekileyo ekusebenzeni kwemigodi nasekwarini. Ukunganyangeki kwayo okuphezulu kunye nokukwazi ukuqina phantsi kweempembelelo kuyenza ibe yinto yokuya kwisixhobo esijongene neemeko ezinzima mihla le. Izixhobo kunye noomatshini kule mizi-mveliso bahlala bejongana nezinto ezirhabaxa, imithwalo enzima, kunye nokungqubana okungapheliyo. Intsimbi yeManganese inyukela kumngeni, yandisa ubomi besixhobo kunye nokunciphisa iindleko zokuyigcina.

Nazi ezinye izicelo eziqhelekileyo:

- Imihlathi yokutyumza: Ezi zixhobo zityumza amatye kunye ne-ores, zinyamezela uxinzelelo olunzima kunye nefuthe. Intsimbi yeManganese iqinisekisa ukuba zihlala ixesha elide.

- Izikrini zegrizzly: Isetyenziselwa ukuhlenga izixhobo, ezi zikrini zizuza kukuqina kwentsimbi ye-manganese kunye nokuchasana nokunxiba.

- Iingqayi zamatye: Le mijelo ikhokela izinto ngoomatshini, apho intsimbi yemanganese ithintela ukhukuliseko ukuba lungahambi rhoqo.

- Iibhakethi zomhlakulo: Emigodini, iiemele zomhlakulo ziqokelela imithwalo enzima yamatye nobutyobo. Intsimbi yeManganese igcina yomelele kwaye ithembekile.

Ngokusebenzisa intsimbi yemanganese kwezi zicelo, amashishini agcina ixesha kunye nemali ngelixa egcina ukusebenza kakuhle. Iipropati zayo ezizodwa zenza ukuba ibaluleke kakhulu kwimigodi kunye nezixhobo zokwembiwa.

Iingoma zikaloliwe kunye noomatshini abanzima

Iindlela zikaloliwe zixhomekeke kwintsimbi yemanganese kwiindlela zazo kunye namalungu. Ukuqina kwesi sixhobo kunye nokumelana nokunxiba kuyenza ilungele ukuphatha ukukhuhlana okungaguqukiyo kunye nemithwalo enzima yoololiwe. Ukwandiswa kwehlabathi kunye nokuphuculwa kothungelwano lukaloliwe kunyuse ngakumbi imfuno yalo.

Iingxelo ezivela kwimakethi yentsimbi ye-austenitic manganese iqaqambisa ukusetyenziswa kwayo ngokubanzi kwicandelo likaloliwe. Abavelisi bayisebenzisela ukuvelisa iingoma ezihlala ixesha elide, ukutshintshwa, kunye nokunqumla okunokumelana neempembelelo eziphindaphindiweyo. Ukukwazi kwayo ukunyamezela le miqathango iqinisekisa ukusebenza kakuhle kunye nokunciphisa imfuno yokutshintshwa rhoqo.

Ukukhula koshishino lukaloliwe kukwanyuse imfuno yentsimbi yemanganese koomatshini abanzima. Ii-Locomotives kunye neemoto zomthwalo zifuna amacandelo anokujongana noxinzelelo oluphezulu kunye nefuthe. Intsimbi yeManganese ihambisa ukusebenza okungenakuthelekiswa nanto, iyenza ibe yinto ekhethwayo kwezi zicelo.

Utyalo-mali kwiziseko zophuhliso lwezothutho luqhubela phambili ukuqhubela phambili ukuveliswa kwezinto ezintsha kubuchwephesha bentsimbi yemanganese. Njengoko iindlela zikaloliwe zanda, le mpahla ihlala isisiseko soshishino, iqinisekisa ukusebenza kakuhle nokuthembeka.

Ulwakhiwo kunye neZixhobo ezineMpembelelo ephezulu

Iindawo zokwakha ziimekobume ezinzima, kwaye izixhobo ezisetyenziswa apho kufuneka zomelele ngakumbi. Intsimbi yeManganese iyakhanya kule ntsimi, inika ukuqina okungenakuthelekiswa nanto kunye nokumelana nempembelelo. Ukususela kwizixhobo zokudiliza ukuya kumazinyo okuhlamba, ukusetyenziswa kwayo kukhulu kwaye kuyahluka.

Thatha izixhobo ezinempembelelo ephezulu, umzekelo. I-Jackhammer bits kunye ne-cut edges ijongene noxinzelelo oluqhubekayo ngexesha lokusetyenziswa. Intsimbi yeManganese iqinisekisa ukuba zihlala zibukhali kwaye zisebenza, nasemva kokuvezwa ixesha elide kwiindawo eziqinileyo. Ngokufanayo, oomatshini bokwakha abafana neebulldoza kunye nezilayishi bayazuza kubuchule bentsimbi yemanganese ukuxhathisa ukuguga nokukrazuka.

Ukongeza kwizixhobo, intsimbi ye-manganese isetyenziswa kumacandelo esakhiwo. Iibhulorho, iibhanti, kunye nezinye izinto ezithwala imithwalo zixhomekeke kumandla ayo ukugcina uzinzo phantsi kwemithwalo enzima. Ukuguquguquka kwayo kwenza ukuba ibe yimpahla exabisekileyo ekwakhiweni, apho ukuqina kunye nokuthembeka kungaxoxiswana.

Ngokubandakanya intsimbi yemanganese kulwakhiwo kunye nezixhobo ezinempembelelo ephezulu, amashishini anokujongana neeprojekthi eziyimfuneko ngokuzithemba. Iimpawu zayo ezizodwa zenza ukuba kube yinto ethembela ngabakhi kunye neenjineli.

Ukuthelekisa intsimbi yeManganese nezinye izinto

I-Advantes in Durability kunye ne-Impact Resistance

Intsimbi yeManganese ibalasele ngokuqina kwayo okukhethekileyo kunye nokukwazi ukumelana neempembelelo. Ukubunjwa kwayo okuyingqayizivele, okubandakanyaamanqanaba aphezulu emanganesekunye nekhabhoni, ivumela ukuba lukhuni kumphezulu ngelixa igcina i-core enzima. Le ndibaniselwano yenza ukuba ilungele iindawo ezinempembelelo ephezulu njengemigodi kunye nokwakhiwa.

Ngokungafaniyo nezinye izinto ezininzi, intsimbi yemanganese inokufunxa amandla abalulekileyo phantsi koxinzelelo. Le propathi, eyaziwa ngokuba kukuqiniswa komsebenzi, yongeza ukuxhathisa kwayo ukunxiba ngokuhamba kwexesha. Umzekelo, kwizicelo ezibandakanya ukukrazula okanye ukuqhawuka koxinzelelo oluphezulu, umphezulu wemathiriyeli uba qina xa usetyenziswa. Nangona kunjalo, ukusebenza kwayo kunokwahluka ngokuxhomekeke kwiimeko. Ngaphantsi kwemithwalo ephakathi okanye ephantsi, intsimbi ye-manganese ayinakho ukuqina ngokufanelekileyo, enokuthi inciphise ukuqina kwayo kwiimeko ezinjalo.

Uphando lubonisa ukuba intsimbi ye-manganese, eyaziwa ngokuba yintsimbi ye-Hadfield, idlula ezinye izinto ekuxhathiseni ukunxiba phantsi kweemeko zempembelelo ephezulu. Ikhono layo lokuzinzisa isigaba se-austenitic kwakhona negalelo ekuqineni kwayo kunye nokusebenza kweendleko xa kuthelekiswa ne-alloys esekelwe kwi-nickel.

Imingeni kunye neMida

Nangona inamandla, intsimbi yemanganese inemingeni ephawulekayo. Omnye umba ophambili ngamandla ayo esivuno sokuqala esisezantsi, esihlala siphakathi kwe-200 MPa kunye ne-300 MPa. Ngelixa izinto ezinokuthi zibe lukhuni phantsi kwempembelelo, le mveliso iphantsi yamandla ingenza ukuba ingasebenzi kakuhle kwizicelo ezinomthwalo ophakathi okanye omileyo.

Olunye umda lubandakanya i-ductility yayo. Ukomeleza amandla entsimbi yemanganese ngokulungiswa rhoqokunciphisa ukuguquguquka kwayo, ukudala urhwebo phakathi kokuqina kunye nokuqina. Ukongezelela, izigaba ezithile, ezifana nesigaba se-hexagonal close-packed (HCP), sinokubumba ngexesha lokucubungula. Ezi zigaba zonyusa umngcipheko wokuqhekeka, nto leyo eyenza kube nzima ngakumbi ukusetyenziswa kwayo kwamanye amashishini.

Izinto ezikhuphisanayo kunye nezinto ezintsha

Ukuphuhliswa kwezinto ezintsha kunye nobuchwepheshe buqalise ukhuphiswano lwentsimbi ye-manganese. Ukuqhubela phambili kuphando lwe-metallurgical kuye kwakhokelela ekudalweni kwe-alloys ephezulu yokusebenza kunye ne-composites ecela umngeni ekulawuleni kwayo.

- Ukuveliswa kwezinto ezintsha kwi-alloys zetsimbi, ezifana neentsimbi ze-manganese eziphakathi, zibonelela ngeempawu eziphuculweyo zoomatshini kunye nokugcinwa kweendleko ngokunciphisa i-alloying elements.

- Ubuchwephesha bokwenza okongeziweyo buvumela ukuveliswa kwezinto eziqhelekileyo ezinezakhiwo ezilungiselelwe usetyenziso oluthile.

- Imizi-mveliso efana neemoto kunye ne-aerospace iqhuba imfuno yezinto ezikhaphukhaphu, ezomelele kakhulu, ezihlala zifuna uvavanyo oluphezulu lwesinyithi ukuqinisekisa ukhuseleko kunye nokuthotyelwa.

Ngelixa intsimbi ye-manganese ihlala ilitye lembombo kumashishini anzima, ezi zinto zintsha ziqaqambisa imfuneko yophando oluqhubekayo ukugcina ukubaluleka kwayo kwimarike ekhuphisanayo.

Intsimbi yeManganese namhlanje kunye neeNdlela zexesha elizayo

Ukusetyenziswa kwemizi-mveliso yanamhlanje

Intsimbi yeManganese iyaqhubeka nokudlalaindima ebalulekileyo kumashishini anamhlanje. Ukomelela kwayo kunye nokuchasana kweempembelelo kuyenza ibaluleke kakhulu kumacandelo afana nolwakhiwo, ezothutho, kunye nokuvelisa. Enyanisweni, i-steelmaking akhawunti ye-85% ukuya kwi-90% yemfuno ye-manganese, igxininisa ukubaluleka kwayo ekuveliseni i-alloys ephezulu.

| Umzi-mveliso/usetyenziso | Ipesenti yeMbango yeManganese |

|---|---|

| Ukwenza intsimbi | 85% ukuya kwi-90% |

| Ulwakhiwo, oomatshini, ezoThutho | Ukusetyenziswa okuphezulu okuphezulu |

| Ukusetyenziswa kwe-nonmetallurgical | Izichumisi zezityalo, ukutya kwezilwanyana, imibala yezitena |

Ngaphaya kokusetyenziswa kwemveli, iialloyi zemanganese zifumana umdla kushishino lweemoto. Izinto ezilula ezenziwe ngentsimbi ye-manganese zinceda ukuphucula ukusebenza kakuhle kwamafutha kunye nokusebenza kokhuseleko. Olu tshintsho luhambelana nemfuno ekhulayo yezisombululo zokonga umbane kwezothutho.

Ukuguquguquka kwentsimbi yeManganese iqinisekisa ukuqhubeka kwayo kumashishini abeka phambili amandla, ukuqina, kunye nokusungula izinto ezintsha.

Uzinzo kunye neenzame zokurisayikilisha

Ukuzinza kuye kwaba yinto ekugxilwe kuyo kakhulu kwishishini lentsimbi, kwaye intsimbi ye-manganese ayinjalo. Ukurisayikilisha kudlala indima ephambili ekucutheni inkcitho kunye nokugcina izixhobo zokusebenza. Iimetrics ezifana ne-End-of-Life Recycling Rate (EoL-RR) kunye neRecycling Process Efficiency Rate (RPER) zivavanya ukuba ziphinda zisetyenziswe njani ngokufanelekileyo izinto ezilahliweyo.

| Isalathisi | Ushunqulelo | Inkcazo emfutshane |

|---|---|---|

| Ireyithi eyonke yokufakwa ngokutsha kwezinto ezisetyenzisiweyo | TS–RIR | Ilinganisa iqhezu legalelo lilonke lokulahlwa kokurisayikilisha ngaphezulu kwegalelo lemathiriyeli iyonke. |

| Ukuphela kobomi bokurisayikilisha | EoL–RR | Ilinganisa iqhezu lenkunkuma endala ephinda isetyenziswe kwitotali yemali eyenziwa ngonyaka. |

| Inkqubo yokurisayikilisha ukusebenza kakuhle | RPER | Ilinganisa iqhezu lezinto ezilahliweyo ezisetyenzisiweyo zizonke ngaphezulu kwegalelo elipheleleyo lokurisayikilishwa. |

Iinzame zokuhlaziya intsimbi yemanganese ayinciphisi nje kuphela impembelelo yokusingqongileyo kodwa ikwaphakamisa ukuzimela ekuboneleleni ngemathiriyeli. La manyathelo ahambelana neenjongo zehlabathi zophuhliso oluzinzileyo, ukuqinisekisa ukuba amashishini angakwazi ukuhlangabezana neemfuno zexesha elizayo ngokufanelekileyo.

Ubuchwephesha obusakhulayo kunye nezicelo

Ikamva lentsimbi yemanganese lijongeka lithembisa, ngenxa yenkqubela phambili yetekhnoloji kunye neemfuno zemizi-mveliso eziphuhlayo. EMzantsi Korea, imakethi yentsimbi ye-manganese ye-boron iyanda ngenxa yosetyenziso lwayo kumacandelo eemoto nawokwakha. Ukunyuka kwezithuthi zombane kunyuse ngakumbi imfuno yezinto ezintsha, kuvula indlela yokusetyenziswa okutsha kwentsimbi yemanganese.

- Intsimbi yeManganese ixhasa itekhnoloji ezinzileyo njengonyango lwamanzi amdaka e-electrolytic manganese.

- Idlala indima ebalulekileyo kwiinkqubo zokugcina amandla kunye nezicelo ze-biomedical.

- Ukudityaniswa kunye nokufunyanwa kwicandelo lentsimbi kuqhuba izinto ezintsha kunye nokukhula kweemarike.

Njengoko amashishini ephonononga izinto ezintsha ezinokwenzeka,intsimbi yemanganese ihlala ililitye lembomboyenkqubela phambili. Iimpawu zayo ezininzi ezisebenzayo ziqinisekisa ukuba ziya kuqhubeka nokuziqhelanisa neendlela ezivelayo kunye nobuchwepheshe.

Intsimbi yeManganese ishiye uphawu olungacimekiyo kwisinyithi nakwimizi-mveliso ukusukela oko yafunyanwa kwinkulungwane ye-19. Umsebenzi wobuvulindlela kaMhlekazi uRobert Hadfield wazisa umbandela onokuthi ube lukhuni ngaphantsi kwempembelelo, ukuguqula izicelo zemigodi, iindlela zikaloliwe nezokwakha. Ngokuhamba kwexesha, ukuqhubela phambili okunje kunyango lobushushu kunye nokuphuculwa kwealloyi kuye kwanyusa iipropathi zayo zoomatshini, iqinisekisa ukufaneleka kwayo okuqhubekayo kwiindawo ezinempembelelo ephezulu.

Iintsimbi eziphakathi-manganese, ezinemixholo ukusuka kwi-3% ukuya kwi-10% yemanganese, ibonisa i-microstructures eyodwa kunye namandla akhethekileyo. Iindlela zemveliso ezinje ngokuguqulwa kunye nokwahlulahlula (i-D&P) zityhalele amandla esivuno ukuya kumanqanaba anomtsalane, zizenza zilungele ukwenza ucinezelo lwezicelo.

Ukujonga phambili, ishishini lijongene nemingeni efana neenkxalabo zokusingqongileyo kunye neendleko eziphezulu zokusebenza. Noko ke, maninzi amathuba. Imfuno ekhulayo yee-alloys ezisekwe kwi-manganese kwimveliso yentsimbi kunye nezisombululo zokugcina amandla avuselelekayo ziqaqambisa ukubaluleka kobuchule bayo.

| Udidi | Iinkcukacha |

|---|---|

| Abaqhubi abakhulu | - Ukukhula ukwamkelwa kwezithuthi zombane kwiibhetri ze-lithium-ion. |

| -Ukwandisa imisebenzi yophuhliso lweziseko ezingundoqo kwihlabathi jikelele. | |

| Izithintelo ezikhoyo | - Imingcipheko yempilo eyayanyaniswa nokuba sesichengeni semanganese. |

| Amathuba avelayo | - Ukuqhubela phambili kubuchwepheshe bezemigodi kunye nezenzo ezizinzileyo. |

Ukukwazi kwentsimbi yeManganese ukuziqhelanisa nobuchwepheshe obusakhulayo iqinisekisa indawo yayo kwikamva loshishino. Ukusuka kwiinkqubo zokugcina amandla ukuya kwi-metallurgy ephezulu, ukuguquguquka kwayo kuyaqhubeka nokuqhuba izinto ezintsha kunye nokuzinza.

FAQ

Yintoni eyenza intsimbi yemanganese ibe yokhethekileyo?

Intsimbi yeManganese yodwakuba iyaqina phantsi kweempembelelo. Le propati, ebizwa ngokuba yi-work hard, iyenza ibe nzima ngakumbi xa isetyenziswa. Ifanelekile kwizixhobo ezinempembelelo ephezulu kunye noomatshini abajongene nokuguga kunye nokukrazula.

Ingaba intsimbi yemanganese inokuphinda isetyenziswe?

Ewe! Ukurisayikilisha intsimbi yemanganese kunceda ukunciphisa inkunkuma kunye nokugcina izixhobo. Amashishini aphinda asebenzise izinto ezilahliweyo ukwenza iimveliso ezintsha, nto leyo eyenze ukuba ibe lukhetho olulungele i-eco-friendly kwimveliso ezinzileyo.

Iphi intsimbi yemanganese edla ngokusetyenziswa?

Uya kufumana intsimbi yemanganese kwizixhobo zemigodi, iingoma zikaloliwe, kunye nezixhobo zokwakha. Ukuqina kwayo kunye nokuchasana neempembelelo kuyenza ilungele imeko apho izixhobo zijongene noxinzelelo olukhulu.

Ngaba intsimbi yemanganese ingcono kunezinye izinto?

Kwiimeko ezinempembelelo ephezulu, intsimbi ye-manganese idlula izinto ezininzi. Iqinile kwaye ihlala ixesha elide. Nangona kunjalo, ayisebenzi kangako kwimithwalo engatshintshiyo okanye usetyenziso olukhaphukhaphu, apho ezinye iialloyi zinokusebenza ngcono.

Intsimbi yemanganese ibanceda njani imizi-mveliso ukuba yonge imali?

Ukumelana kwayo nokunxibakunciphisa imfuno yokutshintshwa rhoqo. Amashishini asebenzisa intsimbi ye-manganese achitha imali encinci kulondolozo kunye nexesha lokunciphisa, ukwandisa ukusebenza kakuhle kunye nokunciphisa iindleko.

Ixesha lokuposa: Jun-09-2025