Izinto zokuphosaiimilo iimveliso njengeUmtshini wokutyumza imihlathi or I-Gyratory Crusher. Banceda ukudala yonke into ukusukaAmacandelo e-Cone Crusheriya kuIsando seNsimbi yeManganese. Ukhetho olufanelekileyo lubalulekile. Jonga le theyibhile ukusuka kwisiseko esiphezulu saseYurophu:

| Imveliso yentsimbi yokuphosa | 23.000 iitoni |

| Ixabiso leSiphene | 5–7% |

Inzululwazi yeMathiriyeli igubungela isinyithi, iiseramikhi, iipolymers, kunye neecomposites. Ukwazi izinto ezifanelekileyo zokuphosa kunceda iinjineli zonyuse umgangatho kwaye zisike inkunkuma.

Izinto eziphambili zokuThatha

- Ukukhetha izinto ezifanelekileyo zokuphosa, njengentsimbi, intsimbi,aluminiyam, okanye iiplastiki, zichaphazela ngokuthe ngqo umgangatho wemveliso, ixabiso kunye nokusebenza.

- Iimathiriyeli zentsimbi zinentsimbi kwaye zomelele kodwa zinokurusa, ngelixa izinto ezingeyontsimbi ezifana ne-aluminiyam kunye nobhedu zixhathisa umhlwa kwaye zikhaphukhaphu.

- Iiplastiki kunye neekeramics zibonelela ngeenzuzo ezizodwa ezifana nokuxhathisa i-corrosion kunye nokunyamezela ubushushu, okwenza kube yinto efanelekileyo kwizicelo ezikhethekileyo.

Iintlobo eziphambili zezinto zokuCasa

Izinto zokuphosa eziFrerous: Intsimbi kunye nentsimbi

Izinto zokuphosa i-ferrous ziquka intsimbi kunye nentsimbi. Ezi zinyithi ziqulethe i-iron njengeyona nto iphambili yazo. Badlala indima enkulu kumatshini onzima kunye nokwakhiwa. Intsimbi kunye nentsimbi zineempawu ezahlukeneyo. Itheyibhile engezantsi ibonisa indlela abathelekisa ngayo:

| Ipropati / Uphawu | Jula i-ayini | Intsimbi (kubandakanya iintsimbi ezithambileyo kunye nekhabhoni) |

|---|---|---|

| Umxholo weCarbon | 2–4.5% | 0.16–2.1% |

| Iipropati zoomatshini | Amandla aphezulu oxinzelelo; brittle | Indunduma; amandla okuqina ayahluka |

| Ukunyangwa kokuMhlwa | Kungcono kumoya ongcolileyo | Igqwala ngokukhawuleza |

| Ubuchule | Kulula (intsimbi engwevu); iqinile (intsimbi emhlophe) | Kuhle, kuyahluka ngohlobo |

| Usetyenziso | Iibhloko ze-injini, ii-rotors ze-brake | Iigiya, imithombo, iinxalenye zeemoto |

Izinto zokuphosa intsimbi zisebenza kakuhle kwiibhloko zenjini kunye nezindlu zokumpompa.Izinto zokuphosa intsimbiingena iigiya, izipringi, kunye neendawo ezininzi zemoto. Uhlobo ngalunye luzisa amandla alo etafileni.

Izinto eziNgena-Ferrous Casting: iAluminiyam, iCopper, iMagnesium, iZinc

Izinto zokuphosa ezingenayo i-ferrous azinayo intsimbi njengento ephambili. I-aluminiyam, ubhedu, i-magnesium, kunye ne-zinc yeli qela. Ezi ntsimbi zikhaphukhaphu kunentsimbi kunye nentsimbi. Imathiriyeli yokuphosa iAluminiyam idumile kumalungu emoto kunye nezakhelo zenqwelomoya. Izinto zokuphosa ubhedu zisebenza kwiindawo zombane kuba ziqhuba kakuhle umbane. I-Magnesium kunye ne-zinc casting materials inceda ukwenza iindawo ezikhaphukhaphu kwizinto zombane kunye nezixhobo. Iintsimbi ezingenayo intsimbi zixhathisa umhlwa kwaye zinika amandla afanelekileyo kubunzima bazo.

Ezinye izinto zokuCasa: iiPlastiki kunye neeCeramics

Ezinye izinto zokuphosa azizontsimbi kwaphela. Iiplastiki kunye neekeramics zibonelela ngeenzuzo ezizodwa. Iiplastiki zinokwenza iimilo ezinzima kwaye zixhathise ukubola. I-Ceramics imela ukushisa okuphezulu. Abantu bamandulo babesebenzisa i-ceramic casting material ukunyibilikisa ubhedu. Iiseramics zanamhlanje, njenge-nano-zirconia, zibonisa ukusebenza okungcono. Banamandla aphezulu okugoba, ukuqina, kunye nokuxhathisa ukukrala. Ezi ceramics zinceda ukwenza amacandelo amancinci, anamandla kwiifowuni kunye neewotshi.

Iiplastiki kunye neekeramics zivula iingcango ezintsha zokuphosa izinto, ngakumbi apho ukumelana nobushushu okanye iimilo ezikhethekileyo zibalulekile.

Iipropati kunye nokuSetyenziswa kweeNdidi zeMathiriyeli yokuphosa

Izinto zokuphosa intsimbi

Imathiriyeli yokuphosa intsimbi ibalasele ngokomelela kwayo kuxinzelelo. Abantu bahlala beyisebenzisela iintsika, iibhloko zenjini, kunye noomatshini abanzima. Intsimbi engwevu iqulethe iiflakes zekhabhoni, ezenza kube lula ukwenza umatshini kodwa zibe brittle. I-iron cast emhlophe, enekhabhoni njenge-iron carbide, inika amandla angcono okuqina kunye nokuguquguquka.

- Amandla:

- Iphatha kakuhle imithwalo enzima.

- Ilungele iindawo ezingagobi kakhulu.

- Ubuthathaka:

- I-brittle kwaye inokophuka phantsi koxinzelelo.

- Ithanda ukuba nomhlwa, ngakumbi kwiindawo ezifumileyo.

Ukongeza izinto ezinje ngesilicon, nickel, okanye ichromium kunokonyusa ukuxhathisa umhlwa kunye nokuqina. Ukupeyintwa rhoqo kunye nokuhlolwa kunceda ukuthintela umhlwa kunye nokugcina iintsimbi ezibunjwe kakuhle.

Uvavanyo lubonisa ukuba isanti esetyenziselwa ukugalela intsimbi inokumelana nobushushu obuphezulu, kodwa umphezulu ongaphezulu uxhomekeke kubungakanani bengqolowa kunye nokumila kwesanti. Oku kuchaphazela indlela egudileyo okanye erhabaxa ngayo imveliso yokugqibela.

Steel Casting Material

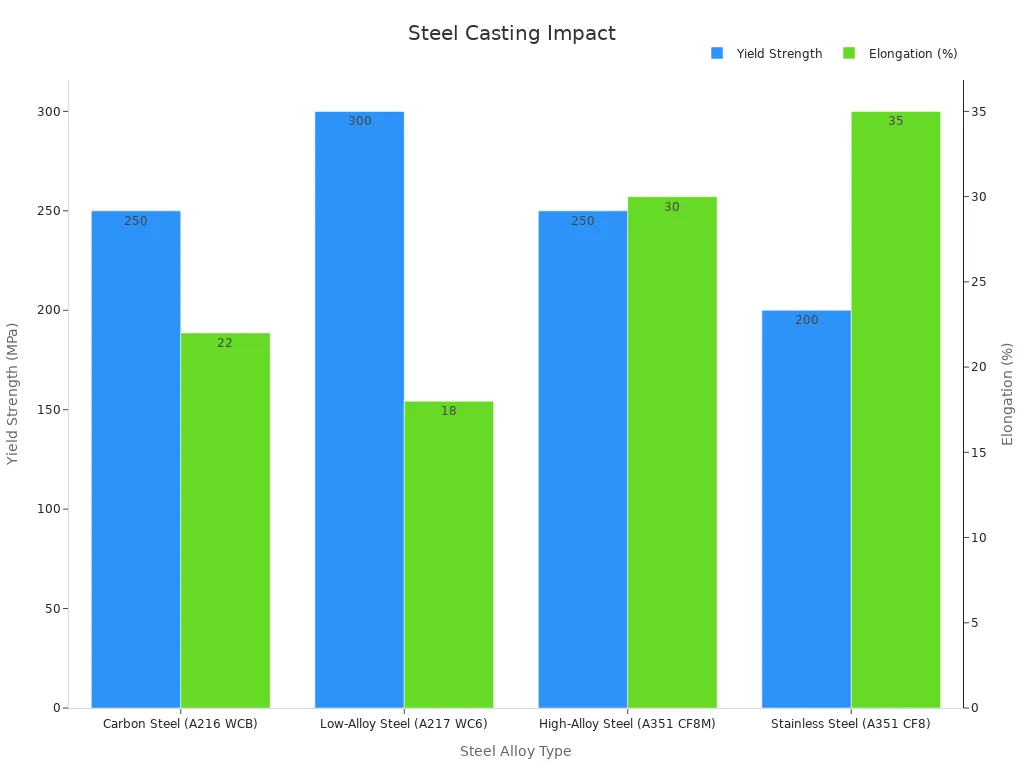

Imathiriyeli yokuphosa isinyithi izisa umxube wamandla, ukudumba, kunye nokuqina. Abantu bakhetha intsimbi yeegiya, iziphethu, kunye neendawo zeemoto kuba ziyakwazi ukumelana noxinzelelo kunye noxinzelelo. Iipropati zentsimbi zitshintsha ngee-alloys ezahlukeneyo kunye nonyango.

| Uhlobo lwe-Steel Alloy | Isivuno Amandla (MPa) | Amandla Okuqina (MPa) | Ubude (%) | Ukunyangwa kokuMhlwa |

|---|---|---|---|---|

| Intsimbi yeCarbon (A216 WCB) | 250 | 450-650 | 22 | Ubuhlwempu |

| Intsimbi ye-Low-Alloy (A217 WC6) | 300 | 550-750 | 18 | Mhle |

| Intsimbi ye-High-Alloy (A351 CF8M) | 250 | 500-700 | 30 | Egqwesileyo |

| Intsimbi engatyiwayo (A351 CF8) | 200 | 450-650 | 35 | Egqwesileyo |

Ukusebenza kwentsimbi kuxhomekeke kwindlela eyenziwe ngayo. Ukupholisa ngokukhawuleza kudala iinkozo ezincinci, okwenza intsimbi ibe yomelele. Ukunyangwa kobushushu kunye neendlela zokuphosa ngononophelo kunokuphucula ukuqina kunye nokunciphisa iziphene ezifana neepores.

I-Aluminiyam yokuCasa izinto

Izinto zokuphosa i-aluminium zithandwa ngenxa yobunzima bayo obulula kunye nokuguquguquka. Ixhaphakile kwiindawo zemoto, iifreyimu zenqwelomoya, nakwizinto zombane. I-aluminiyam igqame ngokomelela kwayo kubunzima obulungileyo kunye nokuxhathisa okugqwesileyo kumhlwa.

| Ipropati/Umba | I-Aluminiyam yokuphosa | Intsimbi yentsimbi | Intsimbi eNgwevu |

|---|---|---|---|

| Ukuxinana | 2.7g/cm³ | 7.7–7.85 g/cm³ | 7.1–7.3 g/cm³ |

| Tensile strength | 100–400 MPa (ukuya kuma-710 MPa kwezinye ialloys) | 340–1800 MPa | 150–400 MPa |

| Indawo yokunyibilika | 570–655°C | 1450–1520°C | 1150–1250°C |

| I-Thermal Conductivity | 120–180 W/m·K | Phakathi | ~46 W/m·K |

| Ukuqhuba koMbane | Kulungile | Ubuhlwempu | Ubuhlwempu |

| Ubuchule | Kulula | Phakathi | Intle kodwa ibuhlungu |

| Ukunyangwa kokuMhlwa | Egqwesileyo | Phakathi | Ubuhlwempu |

| Ukushukuma kweDamping | Phakathi | Kulungile | Egqwesileyo |

| Iindleko | Okuphantsi kwimveliso yobuninzi | Phezulu | Phakathi |

- Izibonelelo:

- Wenza iimilo ezintsonkothileyo ngokuchaneka okuphezulu.

- Igcina amandla ngenxa yendawo esezantsi yokunyibilika.

- Imelana nokukhula, ngoko ihlala ixesha elide ngaphandle.

- Ilungile kwimveliso ephezulu.

- Imida:

- Ayinamandla njengentsimbi.

- Inokuba brittle kwezinye ialloys.

- Ifuna ukulawulwa ngononophelo ukuphepha iziphene ezifana ne-porosity.

Uhlalutyo lwamanani lubonisa ukuba umgangatho we-aluminium uyanyibilika kunye nobukho beziphene kunempembelelo enkulu kumandla kunye nokuqina. Iinjineli zisebenzisa iimvavanyo ezikhethekileyo kunye nesoftware ukujonga nokuphucula umgangatho wokuphosa.

Izinto zokuphosa ubhedu

Izinto zokuphosa ubhedu ziyaziwa ngokusebenza kombane kunye ne-thermal conductivity. Abantu basebenzisa iintsimbi zobhedu kwiindawo zombane, kwimibhobho yamanzi nakwizinto zokuhombisa. Iialloyi zobhedu, ezifana nobhedu kunye nobhedu, zinika amandla angaphezulu kunye nokumelana nokugqwala okungcono.

| Isampulu ye-alloy | Ukuqhutywa koMbane (% IACS) | Ubulukhuni obuncinci (Vickers) | Isivuno Amandla (MPa) |

|---|---|---|---|

| EML-200 | 80% | Xa kuthelekiswa ne-EMI-10 | 614 ± 35 |

| EMI-10 | 60% | Xa kuthelekiswa ne-EML-200 | 625 ± 17 |

Unyango olufana nokupholisa okunzulu kunokonyusa i-conductivity ngaphandle kokuphulukana namandla. Ukongeza izinto ezifana ne-zinc okanye i-tin kunokuphucula ukuxhathisa ukunxiba kunye nokuqina. I-Copper castings isebenza kakuhle kwindawo enzima ngenxa yokuba ixhathisa ukubola, ngakumbi xa ixutywe nezinye izinyithi.

Izinto zokugalela iMagnesium

Imathiriyeli yokuphosa iMagnesium yeyona ikhaphukhaphu kuzo zonke iintsimbi zolwakhiwo. Ilungile kumalungu afuna ukuba namandla kodwa angabinzima, njengasemotweni, kwiinqwelomoya, nakwizinto zombane. I-Magnesium alloys inomlinganiselo ophezulu wamandla-to-weight kwaye kulula ukuwenza ngomatshini.

- Ezona mpawu:

- Ikhaphukhaphu kakhulu, enceda ukonga amafutha ezimotweni.

- Ukuqina okuhle kunye nokuqina.

- Amandla athile aphezulu, ngakumbi kwii-alloys.

Iimvavanyo zovavanyo zibonisa ukuba ukongeza imingxuma okanye iimilo ezikhethekileyo zinokwenza i-magnesium ibe khaphukhaphu ngaphandle kokuphulukana namandla amaninzi. Nangona kunjalo, i-magnesium inokugqwala ngokulula, ngoko ke i-coatings okanye i-alloying elements ihlala isetyenziselwa ukuyikhusela.

Zinc Material yokuphosa

Izinto zokuphosa iZinc zihlala zisetyenziselwa amancinci, aneenkcukacha ezicacileyo. Kulula ukuyijula kwaye igcwalise imibumba kakuhle, iyenza ilunge kakhulu kwiigiya, iithoyi, kunye nehardware. I-zinc alloys inika amandla amahle kunye nokuqina kobunzima babo.

- Izinto eziluncedo:

- Igqwesileyo ekwenzeni iimilo ezintsonkothileyo.

- Ukuxhathisa okulungileyo kokutya.

- Indawo yokunyibilika ephantsi igcina amandla ngexesha lokusasa.

- Imingeni:

- Ayinamandla njengentsimbi okanye ialuminiyam.

- Inokuba brittle ekuhambeni kwexesha, ngakumbi kwiimeko ezibandayo.

I-Zinc castings ixhaphake kwimizi-mveliso yeemoto kunye ne-electronics kuba idibanisa ukuchaneka kunye nokusebenza kakuhle kweendleko.

Izinto zokuphosa zePlastiki

Izinto zokuphosa zeplastiki zivula iindlela ezininzi zokuyila. Ikhaphukhaphu, iyaxhathisa ukubola, kwaye inokuthatha phantse nayiphi na imilo. Abantu basebenzisa iplastiki yokuphosa kwizixhobo zonyango, iimpahla zabathengi, kunye neendawo zemoto.

- Iinkcazelo ngoomatshini:

- Amandla, ukuqina, kunye nokuqina kuxhomekeke kuhlobo lweplastiki kunye nendlela eyenziwe ngayo.

- Ukongeza iifayibha ezifana nekhabhoni okanye iglasi kunokwenza iiplastiki zomelele kakhulu.

| Ipropati / Izinto | Woodcast® | Izinto zokugalela zokwenziwa | IPlaster yaseParis (PoP) |

|---|---|---|---|

| Amandla oxinzelelo | Phezulu | Ngasezantsi | Brittle |

| Tensile strength | Ngasezantsi | Phezulu | Brittle |

| Amandla eFlexural (MPa) | 14.24 | 12.93–18.96 | N / A |

| Ukumelana naManzi | Kulungile | Iyahluka | Ubuhlwempu |

Iiplastiki zeplastiki zinokuphatha amanzi kunye nokufudumala kakuhle, kuxhomekeke kwizinto eziphathekayo. Ezinye azinatyhefu kwaye zikhuselekile ukuba zisetyenziswe kunyango. Ezinye zisenokuba neekhemikhali ezifuna ukuphathwa ngononophelo.

Izinto zokuCasa ngeCeramic

I-Ceramic casting material ivelele ngokukwazi kwayo ukuphatha ukushisa okuphezulu. I-Ceramics iqinile, ayigugi, kwaye ayirusi. Abantu bazisebenzisa kwi-electronics, i-aerospace, kunye nezacholo.

- Iinkcazelo ngeThermal:

- Iyakwazi ukumelana namaqondo obushushu ukuya ku 1300°C.

- Igqwesileyo kwi-insulation kunye nezikhuselo zobushushu.

- Ukomelela:

- Iintsinga zeceramic eziguquguqukayo zingasetyenziselwa ukugquma okuphinda kusetyenziswe kwiziphekepheke.

- I-ceramics eziphambili zidibanisa amandla aphezulu kunye ne-conductivity ephantsi ye-thermal.

Abaphandi baye baphuhlisa izinto ezintsha ze-ceramic ezomelele kwaye zibhetyebhetye, zizenza zilungele iimeko ezingqongileyo ezigqithisileyo njengendawo okanye ukwenziwa kobuchwepheshe obuphezulu.

Izinto zokuphosa i-Ceramic zigcina imilo kunye namandla abo naphantsi kobushushu obukhulu, obenza ukuba baxabiseke kwizicelo ezininzi zanamhlanje.

Ukukhetha imathiriyeli efanelekileyo yokuphosa ibumba umgangatho wemveliso, ixabiso, kunye nokusebenza. Iinjineli zithelekisa iindlela zokuphosa kunye neepropathi zisebenzisa iitafile kunye nezifundo zangempela zehlabathi ukuze zitshatise imathiriyeli nganye ekusetyenzisweni kwayo kakuhle. Ukwazi ezi nkcukacha kunceda amaqela ayile iindawo ezingcono, onge imali, kwaye aphephe iimpazamo ezibiza kakhulu.

FAQ

Ngowuphi umahluko ophambili phakathi kwezixhobo zokuphosa i-ferrous kunye ne-non-ferrous?

Izinto ezityebileyo zinentsimbi. Izinto ezingezizo i-ferrous azenzi. Iintlobo ze-ferrous zihlala zinobunzima obukhulu kwaye ziyakhawuleza. Iintlobo ze-non-ferrous zixhathisa umhlwa kwaye ziziva zikhaphukhaphu.

Kutheni iinjineli zikhetha i-aluminiyam yokuphosa?

I-aluminiyam inobunzima obungaphantsi kwentsimbi. Ixhathisa umhlwa kwaye imilo ngokulula. Iinjineli ziyayithanda iinxalenye zemoto, iifreyimu zenqwelomoya, kunye nombane.

Ngaba iiplastiki kunye neeseramikhi ziyakwazi ukuphatha ukushisa okuphezulu?

I-Ceramics ibamba ukushisa okuphezulu kakhulu. Iiplastiki zidla ngokunyibilika kumaqondo obushushu asezantsi. Iinjineli zikhetha iiseramikhi zee-oveni okanye ii-injini, ngelixa iiplastiki zilingana nemisebenzi epholileyo.

Ixesha lokuposa: Jun-17-2025