Iipropati zezinto zesondlo zidlala indima ebalulekileyo ekumiseleni ubomi benkonzoiindawo zokutyumza umhlathi. AbaSebenzi abalawula ubulukhuni, ukuqina, ubungakanani bamasuntswana, kunye nokufuma kunokwandisa ixesha lokuphilaintsimbi yemanganese iindawo zokugutyula imihlathi.

- Ubulukhuni obuphezulu kunye nokukrala konyusa amazinga okutshintsha kunye nokusetyenziswa kwamandla.

- Ukufuma kunye nokuncamathela kunokubangela ukuplaga, okukhokelela kulondolozo olungakumbi.

- Ubungakanani bokutya obuhambelanayo bunceda ukuthintela ixesha lokuphumla kunye nokuphucula ukusebenza kwe-crusher.

Ukukhetha okulungileyoumatshini wokutyumza imihlathikwayeiindawo zokutyumzayehlisa iindleko kwaye inyusa ukusebenza kakuhle.

Izinto eziphambili zokuThatha

- Ukuqina kunye nokuqina kwezixhobo zesondlo kwandisa kakhulu ukuguga kwiindawo zokutyumza imihlathi, ngoko ke abaqhubi kufuneka bahlengahlengise iisetingi kwaye bakhethe izixhobo ezomeleleyo zokwandisa ubomi benxalenye.

- Ukulawula ubungakanani bokutya kunye nokususa amatye amakhulu okanye iifayini kunceda ukuthintela ukunxiba okungalinganiyo kunye nokuvalwa, ukuphuculaukusebenza kakuhle isityumzikunye nokunciphisa ulondolozo.

- Ukufuma kunye nezixhobo ezincangathi zibangela ukuvaleka kunye noxinzelelo olongezelelweyo kwiindawo zokutyumza, ngoko ke ukulawula ukufuma ngokumisa kunye nokuhlola kugcina izityumsi zisebenza kakuhle.

- Ukukhetha ekuneneizixhobo zepleyiti yomhlathikunye noyilo olusekwe kwiipropathi zesondlo zinokuphinda-phinda ubomi bokunxiba kunye nexesha elisezantsi lokuphumla.

- Ukuhlolwa rhoqo, ukugcinwa okufanelekileyo, kunye noqeqesho lomsebenzisi kubalulekile ukuqaphela ukuguga kwangethuba kwaye ugcine izityumsi zisebenza ngokufanelekileyo ixesha elide.

IiPropati zeMathiriyeli yeSifundo esiPhambili kunye neSinxibo sikaMatshini weSityuli semihlathi

Ukuqina Kwezinto Zokutya

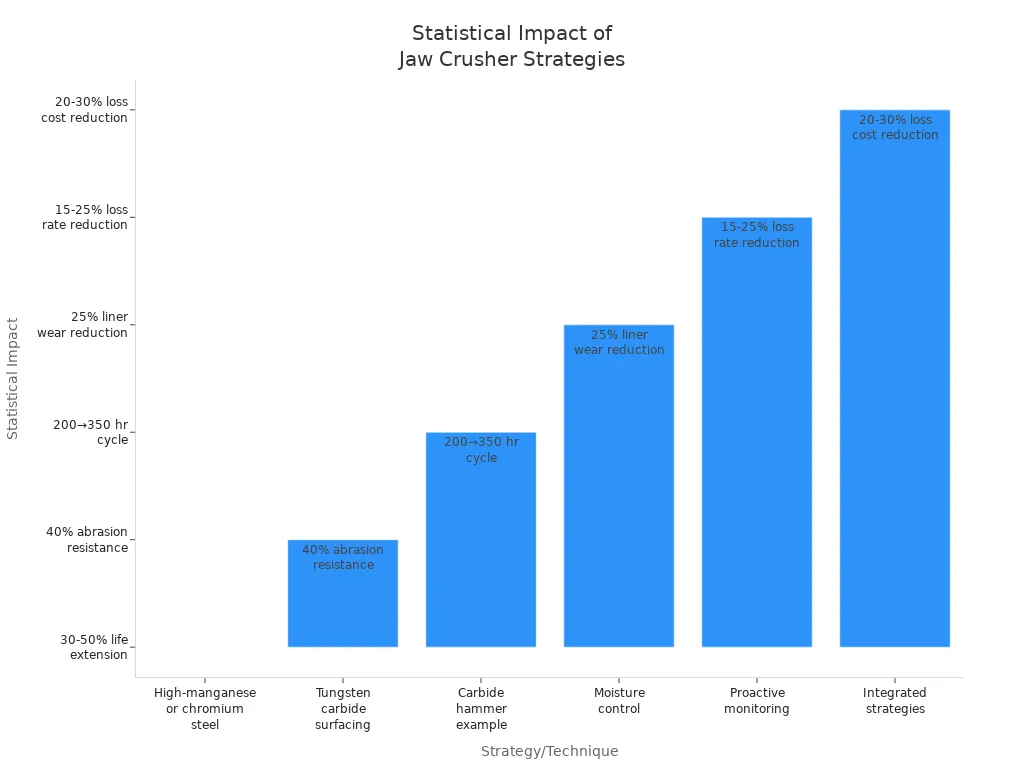

Ukuqina kugqame njengenye yezona zinto zibalulekileyo ezichaphazela ukunxitywa kwesityutyu semihlathi. Amatye anzima, afana negranite okanye i-basalt, afuna amandla amaninzi okuchoboza. La mandla ongezelelweyo kwandisa uxinzelelo kwiipleyiti zemihlathi kunye ne-liners. Xa abaqhubi besondla izinto ezilukhuni ngakumbi kumatshini wokutyumza imihlathi, iipleyiti zifumana ukusika ngakumbi kunye nokunxiba ukunxiba. Uphononongo lubonisa ukuba amatye anamandla acinezelayo aphezulu kunye nokuqina kokuqhekeka abangela ukunxiba ngokukhawuleza. Abaqhubi bahlala beqaphela ukuba ukuphela kokukhululwa kwemihlathi kuguga kuqala xa kusetyenzwa amancinci, amasuntswana anzima. Ukulungelelanisa iisetingi ze-crusher ngokusekelwe kubunzima bokutya kunokuncedisa ukunciphisa ukunxiba kunye nokwandisa ubomi benxalenye.

I-Abrasiveness kunye neMineral Composition

I-Abrasiveness kunye ne-mineral composition nayo idlala indima enkulu kwiipatheni zokunxiba. Iiminerali ezifana ne-quartzite kunye negranite ziyingozi kakhulu. Ezi zimbiwa zisila ngokuchasene neepleyiti zemihlathi, zibangela ukuwohloka okukhawulezileyo komphezulu. Ukuba ukutya kuqulethe ipesenti ephezulu yamaminerali abrasive, umgangathoiintambo zentsimbi yemanganeseinokuphela ngokukhawuleza. Ukukhetha izinto ezifanelekileyo zelinen, ezifana nentsimbi ephezulu ye-chrome okanye i-alloys edibeneyo, inokunceda ukuxhathisa olu hlobo lokugqoka. Abasebenzisi kufuneka bajonge ungcoliseko kwifidi, njengoko i-iron yetramp okanye amatye amakhulu anokubangela ukuqhekeka komphetho kunye nokuqhekeka.

Icebiso: Ukuthelekisa imathiriyeli ye-liner kunye nokwakhiwa kweeminerali zesondlo kunokwandisa ubomi bokunxiba ukuya kuthi ga kahlanu kunye nokunciphisa iindleko zokugcinwa.

Ubungakanani beNcam kunye noBubungakanani boSabelo

Ubungakanani besuntswana kunye nokuhanjiswa kwayo ngokuthe ngqo kuchaphazela kaninzi kangakanani iipleyiti zemihlathi zifuna ukutshintshwa. Xa ukutya kuqulethe amatye amaninzi amaninzi, iindawo ezithile zemihlathi zifumana iimpembelelo eziphindaphindiweyo. Oku kukhokelela ekunxibeni okungalinganiyo kunye nokutshintshwa rhoqo. Izohlwayo ezigqithisileyo kwisondlo zingabangela izithintelo, eziphinda zinciphise ixesha lokuphila kwamacwecwe. Ukuhanjiswa kobungakanani bokutya okulawulwa kakuhle kukhuthaza nokunxiba nokusebenza okuzinzileyo. Abasebenzisi abajonga kwaye bahlengahlengise ubungakanani bokutya banokunciphisa iindleko zokusebenza kwaye bagcine umatshini wokutyumza umhlathi usebenza ngokufanelekileyo.

Umxholo wokufuma kunye nokuncamathela

Isiqulatho sokufuma kwizinto zesondlo sidlala indima ebalulekileyo ekusebenzeni kwesityumzi somhlathi. Xa izinto zokutya ziqulethe ukufuma okuphezulu, ngakumbi xa zixutywe kunye neentlawulo okanye udongwe, zihlala zikhokelela kwimingeni yokusebenza. Izinto ezincangathi zikholisa ukubambelela kwimigangatho engaphakathi kwesityumzi. Oku kuncamathela kunokubangela iibhloko, ezikwabizwa ngokuba yi-clogging, ephazamisa inkqubo yokutyumza.

Abanini-zithuthi badla ngokuphawula ukuba izinto ezintle ezifumileyo, ezinjengodongwe, aziqhekeki ngokulula. Endaweni yoko, ezi zixhobo zidibanisa zibe bubunzima obuxineneyo ngaphakathi kwegumbi lokutyumza. Le nkqubo, ebizwa ngokuba "yi-pancaking," yongeza umthwalo kwi-motor yesityuli. Ukuba ayikhange ihlolwe, i-pancaking inokumisa isityuli ngokupheleleyo. Nangona ukufuma kunganyusi ngokuthe ngqo isantya sokunxitywa kweepleyiti zemihlathi okanye iilayini, ukuvaleka okubangelwa kukuvala kunye nokugcwala kwemoto kunokunciphisa ukusebenza kakuhle kwaye kunokukhokelela ekunxibeni ngokukhawuleza kwexesha.

Amanyathelo athile asebenzayo anceda ukulawula ukufuma kunye nokuncamathela kwimathiriyeli yokutya:

- Ukomisa kwangaphambili umxhesho ukunciphisa ubumanzi obungaphantsi kwe-5% kunceda ukuthintela ukuncamathela.

- Ukuhlola izohlwayo phambi kokuba utyise isityuli kunciphisa umngcipheko wokuvala.

- Ukufakela ii-anti-stick liners, ezifana ne-Teflon-coated surfaces kwi-feed chutes, kunciphisa ukunamathela kwezinto.

- Ukusebenzisa iindonga ze-baffle ukwalathisa ukuhamba kwemathiriyeli, ngakumbi nge-vibrating feeders, kunokunciphisa ngakumbi ukuvaleka.

Qaphela: AbaSebenzi abajonga amanqanaba okufuma kwaye bahlengahlengise iinkqubo zabo banokugcina ukusebenza okugudileyo kokutyumza kunye nokwandisa ubomi beendawo zokunxiba.

Ukulawula ukufuma kunye nokuncamathela kwizinto zokutya akuphuculi nje ukuthembeka kwe-crusher kodwa kuthoba iindleko zokulondolozwa. Ngokuthatha la manyathelo, abaqhubi baqinisekisa ukuba oomatshini bokutyumza imihlathi basebenza kakuhle, naxa belungisa imathiriyeli ecela umngeni.

Impembelelo yeePropati zokuFundisa kuMalungu oMatshini weMihlathi

Iimpembelelo zoBulukhuni kwi-Jaw Plate kunye ne-Liner Wear

Ubunzima bezinto zokutya buchaphazela ngokuthe ngqo izinga lokugqoka iiplati zemihlathi kunye ne-liners. Amatye aqinileyo, afana negranite okanye iquartzite, afuna amandla angakumbi ukuze aphuke. La mandla onyukayo akhokelela kuxinzelelo oluphezulu kwimiphezulu yoqhagamshelwano yesityuli somhlathi. Ngokuhamba kwexesha, iimpembelelo eziphindaphindiweyo ezivela kwizinto ezinzima zibangela ukuguga kwe-chisel cut, ebonakala njengemikrwelo enzulu, i-grooves, kunye nemingxuma kwiipleyiti zemihlathi. Abaqhubi bahlala bebona ukuba iindawo ezityumzayo zifumana ezona zinxibo ziqatha, ngakumbi xa kusetyenzwa ngobulukhuni be-ores.

Ukukhathala kwakhona kukhula xa iipleyiti zemihlathi zijongene noxinzelelo oluphindaphindiweyo kunye nemithwalo yempembelelo. Iintanda zenza kwaye zisasazeke, ekugqibeleni zibangele i-brittle fractures. Indawo yokutya, apho amatye aqala ukungena kwi-crusher, isengozini kakhulu kulolu hlobo lomonakalo.Iipleyiti zentsimbi ye-manganese ephezuluzingamelana nokunye koku kunxitywa ngenxa yokuba zisebenza nzima ngexesha lokusebenza, kodwa nezi zixhobo zinemida xa zibekwe kwisondlo esinzima kakhulu.

Icebiso: Ukubeka iliso rhoqo ubunzima bezinto ezingenayo kunceda abaqhubi bahlengahlengise izicwangciso ze-crusher kwaye bakhethe izixhobo ezifanelekileyo ze-liner, ukunciphisa ixesha elingalindelekanga.

IiMinerali eziAbrasive kunye nokuNcitshiswa koMphezulu

Amaminerali abrasive kwisondlo, njenge-quartz okanye i-silica, akhawulezisa ukuthotywa komhlabaiindawo zokutyumza umhlathi. Iimvavanyo ze-abrasion zaseLabhoratri, ezibandakanya iimvavanyo ze-gouging abrasion, zibonisa ulungelelwaniso olomeleleyo kunye neepateni zokunxiba zelizwe lokwenyani. Olu vavanyo lubonisa ukuba iiminerali ezirhabaxa zibangela ukulinywa kwemicroploughing, microcutting, kunye ne microcracking kumphezulu weepleyiti zemihlathi kunye neeliner. Njengoko amasuntswana abrasive islayidi kwaye acinezele ngokuchasene nentsimbi, asusa amaqhekeza amancinci, akhokelela ekulahlekeni komthamo kunye neendawo ezirhabaxa.

Uphononongo lwasendle luqinisekisa ukuba ubukho beeminerali ezirhabaxa bonyusa izinga lokunxiba komphezulu. Iindlela eziphambili zokunxiba ziquka:

- Uxinzelelo oluphantsi lokukrwempa ibrasion:Kwenzeka xa amasuntswana etyibilika phezu komhlaba ngaphandle koxinzelelo olukhulu.

- I-brasion yokusila yoxinzelelo oluphezulu:Yenzeka xa amasuntswana amancinci agaya kumphezulu phantsi koxinzelelo.

- Ukukrazula kwe-abrasion:Iziphumo ezivela kumasuntswana amakhulu, aqinileyo achaphazela kwaye acinezela amacwecwe emihlathi.

Itheyibhile engezantsi ishwankathela iipatheni zokunxiba eziqhelekileyo kunye nezizathu zazo:

| Nxiba iPatheni yohlobo | Inkcazo | Unobangela / Imiba enempembelelo | Inqila yePlayithi yoMhlathi | Ukunyanzeliswa kweempawu |

|---|---|---|---|---|

| I-Chisel Cutting Wear | Imikrwelo enzulu, iigrooves, kunye nemingxuma | Impembelelo ephindaphindiweyo kunye ne-extrusion yi-ores | Iindawo zokutyumza (M, ML, L) | I-tangential ephezulu, ephakathi |

| Ukukhathala Ukunxiba | Iintanda kunye nokuqhekeka kwamathambo | Impembelelo ephindaphindiweyo yexesha elide | Indawo yokutya (H) | Umgangatho ophezulu oqhelekileyo, ophantsi we-tangential |

| I-Abrasive Wear | Ukukrwela, ukucola, ukukrazuka | Ubungakanani besuntswana, ubulukhuni, ukucinezela/ukucheba | Iindawo zokutyumza (M, ML, L) | High eqhelekileyo kunye tangential |

| I-Corrosion Wear | I-oxidation ngenxa yokufuma | Umxholo wokufuma kwisondlo | Yonke imimandla | Ukunxitywa kweekhemikhali |

Iipropathi zezinto eziphathekayo ezinje ngokuqina, ukuqina, kunye ne-microstructure zikwaphembelela ukuba iinxalenye zesityuli semihlathi zixhathisa njani ukunxitywa kwe-abrasive. Utshintsho kwijometri ye-liner ukusuka ekunxityweni kunokuchaphazela ukusebenza kwe-crusher, ukwenza ukuhlolwa rhoqo kubalulekile.

Ukutya Okugqithisileyo kunye nempembelelo yoMxholo weZohlwayo

Ukuhanjiswa kobungakanani bokutya kudlala indima enkulu kwipleyiti yomhlathi kunye nokunxiba kwe-liner. Amatye amakhulu kakhulu enza imimandla yempembelelo egxininisiweyo kwiipleyiti zemihlathi. Ezi mpembelelo zibangela ukuguga okungalinganiyo, kunye neendawo ezithile eziguga ngokukhawuleza kunezinye. Xa amasuntswana amakhulu angena kwi-crusher, anokubangela i-gouging abrasion, ekhokelela kwi-grooves enzulu kunye nemigodi.

Izohlwayo ezigqithisileyo kwisondlo zinika umngeni owahlukileyo. Amasuntswana amahle angazalisa izikhewu phakathi kwamatye amakhulu, anyuse umngcipheko wokuvaleka. Ezi zithintelo zinyanzelisa i-crusher ukuba isebenze nzima, iphakamisa ubushushu kunye noxinzelelo kwiindawo zokunxiba. Ngokuhamba kwexesha, oku kunokukhawuleza ukuguga kunye nokukhathala, ngakumbi ukuba iintlawulo ziqulethe iiminerali ezixubileyo.

Abasebenzisi bangalawula le ngozi ngokuthi:

- Ukuhlola izinto zokutya ukususa izohlwayo ezigqithisileyo ngaphambi kokuba zingene kwi-crusher.

- Ukulungelelanisa isethingi yecala elivaliweyo (CSS) ukulawula ubungakanani bezinto ezidlulayo.

- Ukubeka iliso kwisixa samatye amakhulu kunye nokulungelelanisa ilungiselelo lesondlo.

Qaphela: Ubungakanani besondlo obungaguqukiyo kunye nomxholo wezohlwayo olawulwayo kunceda ukugcina nokunxiba kwiipleyiti zemihlathi, ukuphucula ukusebenza kakuhle kunye nobomi bomatshini wokutyumza imihlathi.

IiNdlela zokuNxitywa ezinxulumene nokufuma

Ukufuma kwizinto zokutya kunokutshintsha indlela iinxalenye zemihlathi ezinxiba ngayo ngexesha lokusebenza. Amanzi asebenza njenge-lubricant kunye ne-catalyst yokugqoka, ngokuxhomekeke kwiimeko ezingaphakathi kwi-crusher. Abaqhubi bahlala bebona iipatheni ezahlukeneyo zokunxiba xa belungisa izinto ezimanzi okanye ezincangathi xa kuthelekiswa namatye omileyo, ahamba ngokukhululekileyo.

Iziphumo ezithe ngqo zokufuma kwiNxitywa:

- Amanzi anokwenza ifilimu encinci phakathi kwelitye kunye nepleyiti yomhlathi. Le filimu ngamanye amaxesha inciphisa ukukhuhlana, okunciphisa ukunxiba kwe-abrasive.

- Kwiimeko ezininzi, ukufuma kuxutywa namasuntswana amahle kunye nodongwe. Lo mxube wenza intlama encangathi encamathela kwiipleyiti zemihlathi kunye neeliner.

- Izinto ezincangathi zibangela "i-pancaking," apho iileya zezohlwayo ezimanzi zikhula kwindawo yokutyumza. Ezi maleko zibamba amasuntswana abrasive kunye nokwandisa isenzo sokusila ngokuchasene nesinyithi.

Iziphumo ezingathanga ngqo kunye nomonakalo wesibini:

- Ubumanzi bukhuthaza ukubola, ngakumbi xa kudityaniswe neeminerali eziphendula ngamanzi. I-Corrosion yenza buthathaka umphezulu weepleyiti zemihlathi kunye ne-liners, ibenze babe sesichengeni sokunxitywa koomatshini.

- Isixhobo sokutya esimanzi sikholisa ukukhokelela kwizithintelo. Xa ijam ye-crusher, umatshini kufuneka usebenze ngakumbi ukucima umqobo. La mandla ongezelelweyo anyusa uxinzelelo kwiindawo zokunxiba.

- Isiqulatho sokufuma esiphezulu sinokubangela ukuguga okungalinganiyo. Eminye imimandla yepleyiti yomhlathi inokuhlala igutyungelwe yinto emanzi, ngelixa ezinye zihlala zityhilekile. Lo mahluko ukhokelela kwiipateni zokunxiba ezinqabileyo kwaye unciphisa ubomi obupheleleyo bamalungu.

Phawula:Abanini-zithuthi kufuneka babeke iliso kokubini isiqulatho sokufuma kunye nodidi lwezohlwayo kwifidi. Izinto ezityebileyo ngodongwe ezinomthamo wamanzi aphezulu zibangela ukuguga kakhulu kunesanti ecocekileyo, emanzi.

IiNdlela zokuNxitywa eziNxibelelana nokufuma:

| Inkqubo | Inkcazo | Isiphumo esiqhelekileyo |

|---|---|---|

| Isiphumo sokuthambisa | Ifilimu yamanzi inciphisa ukungqubana | Ukunxiba okune-abrasive kancinci |

| I-Pancaking / Yakha-up | Izohlwayo ezincangathi zibambelela kumphezulu | Ukunyuka kokusila kunye nokuguga |

| Impahla Eyonakalisayo | Amanzi kunye neeminerali zibangela ukusabela kweekhemikhali | Umhlwa, imingxuma, ukulahleka komhlaba |

| Uxinzelelo olubangelwa kukuVimba | Izinto ezimanzi zivala i-crusher, ziphakamisa umthwalo | Ukudinwa okukhawulezileyo kunye nokunxiba |

| Iipateni zokunxiba ezingalinganiyo | Ubumanzi bukhusela iindawo ezithile, buveza ezinye | Isinxibo esinerhewu, esingalindelekanga |

Amanyathelo aSebenzayo okulawula iNdlela eNxulumana nokufuma:

- Abasebenzisi banokujonga kwangaphambili isikrini ukuze basuse izohlwayo ezigqithisileyo kunye nodongwe ngaphambi kokutyumza.

- Ukufakela izinzwa zokufuma kunceda ukulandelela utshintsho kwiimeko zokutya.

- Ukusebenzisa ii-anti-stick liners okanye ii-coatings kwii-chutes kunye ne-crusher surfaces kunciphisa ukwakhiwa kwezinto.

- Ukucoca rhoqo kunye nokuhlolwa kuthintela umonakalo wexesha elide kwi-corrosion kunye nezithintelo.

Ingcebiso:Abasebenzi abalawula ukufuma kunye nezohlwayo kwisondlo banokwandisa ubomi beendawo zokutyumza imihlathi kunye nokunciphisa ixesha lokuphumla elingacwangciswanga.

Iindlela zokunxiba ezinxulumene nokufuma zibonakalisa imiceli mngeni eyodwa ekucutheni kwemizi-mveliso. Ngokuqonda ezi ziphumo, abaqhubi bangenza izigqibo ezingcono malunga nokulungiselela ukutya, izicwangciso zesityuli, kunye neeshedyuli zokugcinwa. Olu lwazi lukhokelela kubomi obude kunye nokusebenza okuthembekileyo kwe-crusher.

Izifundo ze-Industrial Case: Ukusebenza koMatshini weMihlathi

Ukucutshungulwa kokuqina kwentsimbi ephezulu

Imisebenzi yokwembiwa kwemigodi ihlala iqhuba iintsimbi ezinobunzima obuphezulu kakhulu, njengegranite okanye iquartzite. Ezi zixhobo zibeka uxinzelelo olugqithisileyo kwiindawo zokutyumza imihlathi. Abasebenzi baqaphela ukuba iipleyiti zemihlathi kunye neeliner ziguga ngokukhawuleza xa kutyunyuzwa la matye aqinileyo. Iipleyiti zentsimbi eziphakamileyo zemanganese zinceda ukuxhathisa oku kunxitywa kuba ziba nzima ngexesha lokusetyenziswa. Kwindawo enye yemigodi, abaqhubi batshintshela kwiipleyiti zemihlathi yesiko kunye neprofayili yezinyo elikhethekileyo. Olu tshintsho luphucule ubomi bokunxiba kwaye lwanciphisa inani lokuvalwa kokulungisa. Ukuhlolwa rhoqo kunye nokutshintshwa kwangethuba kwamalungu agugileyo kwagcina isityumzi sisebenza kakuhle. Abaqhubi baphinde bahlengahlengisa ilungiselelo lesondlo ukunqanda ukulayisha kakhulu umatshini.

Imveliso yeAbrasive Aggregate

Imveliso ye-abrasive aggregate, efana nokutyumza i-basalt okanye i-quartz-rich gravel, idala indawo enzima kwiindawo zokutyumza imihlathi. Abasebenzisi babona ukukrazula okuphezulu kunye namandla empembelelo kwezi setingi. Basebenzisa izinto ezikumgangatho ophezulu njengentsimbi yemanganese kwiipleyiti zemihlathi ngenxa yeempawu zayo zokuqina. Ubume kunye neprofayili yamazinyo yamacwecwe adlala indima ebalulekileyo ekulawuleni ukunxiba. Ukwenza ngokwezifiso iindawo zokunxiba kwi-aggregate ethile kunceda ukusasaza ukunxiba ngokulinganayo kwaye kwandisa ukusebenza kakuhle. Abasebenzi kwezi ndawo balandela iishedyuli ezingqongqo zogcino. Batshintsha iindawo ngexesha elifanelekileyo ukuthintela ukusilela okungalindelekanga.

- Iinxalenye zokunxiba zesityutyusi somhlathi zijongana nokukrazuka okubalulekileyo kunye namandla empembelelo kwimveliso yeabrasive aggregate.

- Izinto ezikumgangatho ophezulu kunye noyilo lwesiko lunceda ukuxhathisa ukunxiba kunye nokuphucula ukusebenza kakuhle.

- Ixesha lokuyigcina libalulekile ekwandiseni ubomi bokunxiba.

Itheyibhile engezantsi ishwankathela iiyantlukwano phakathi kwe-abrasive kunye ne-abrasive applications encinci:

| Uhlobo lwesicelo | Ireyithi yokunxiba | Izinto Ezisetyenziswayo | Iimfuno Zokulondolozwa |

|---|---|---|---|

| Abrasive Aggregate | Phezulu | Intsimbi yeManganese | Rhoqo, Lucwangcisiwe |

| I-Abrasive encinci | Ngasezantsi | Ii-alloys eziqhelekileyo | Ngaphantsi Rhoqo |

Ubungakanani besondlo esiguquguqukayo kwizicelo zokuphinda zisetyenziswe

Imisebenzi yokuhlaziya ikholisa ukujongana nemathiriyeli yesondlo eyahluka ngobungakanani kunye nokumila. Oku kuguquguquka kuchaphazela ukusebenza komatshini wokutyumza imihlathi kunye nobomi obude. Abaqhubi ngamanye amaxesha babona ukuvala okanye ukumisa umatshini xa isondlo sineziqwenga ezinkulu okanye ezingaqhelekanga. Ukufuduswa kwemihlathi yesityuli kutshintsha kunye nokuphakama kwesondlo, okuchaphazela ukusebenza kakuhle. Ngaphambi kokukhetha isityuli somhlathi ukuze siphinde sisetyenziswe, abaqhubi bahlalutya iimpawu zezinto kunye nobukhulu obulindelekileyo bokutya. Ukusetyenziswa kwamandla kwakhona kuxhomekeke kumandla wezinto kunye nobungakanani bokuvuleka komtshiso. Ukutyumza ikhonkrithi yokuqina okuphezulu kusebenzisa amandla amaninzi kunezixhobo ezithambileyo. Ubungakanani bomngxunya obuncinci nabo bonyusa ukusetyenziswa kwamandla. Ezi zinto zibonisa ukuba ubungakanani bokutya okuguquguqukayo kunye neempawu eziphathekayo zidlala indima enkulu ekusebenzeni kwe-crusher kunye nokunxiba inxalenye yobomi.

Abasebenzisi abajonga ubungakanani bokutya kunye nokulungelelanisa useto lwesityuli banokunciphisa ukuguga kunye nokuphucula ukusebenza kakuhle kwizicelo zokuphinda zisetyenziswe.

Ukubeka iliso kunye nokuNcitshiswa kokuNxitywa kwiMithi yokuSebenza koMshini we-Crusher

Ukukhetha i-Jaw Plate kunye ne-Liner Materials

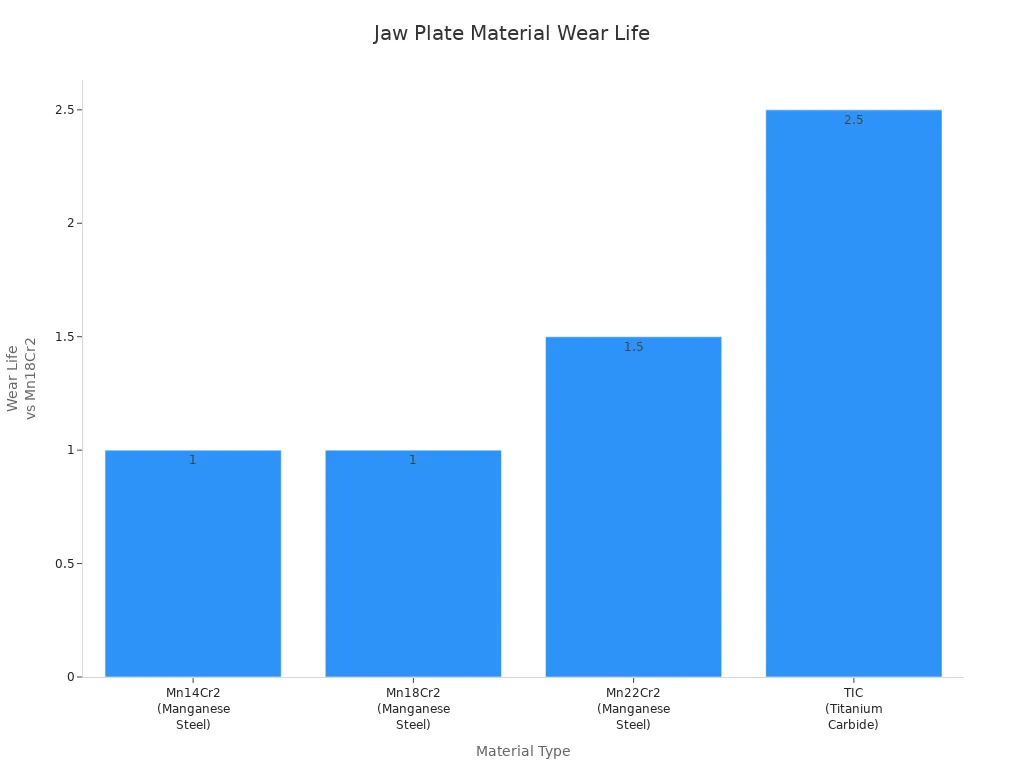

Ukukhetha okulungileyoipleyiti yomhlathi kunye nezixhobo zombaneibalulekile ekunciphiseni ukunxiba kwizityuli zamashishini. Abaqhubi bahlala bekhetha amanqanaba entsimbi ye-manganese esekelwe kubulukhuni kunye nokuqina kwesondlo. Itheyibhile engezantsi ithelekisa izinto eziqhelekileyo kunye nokusebenza kwazo:

| Uhlobo lwezinto eziphathekayo | Iimpawu eziphambili | Ukufaneleka kweZixhobo eziNqinileyo/ eziAbrasive | UBomi bokunxiba xa buthelekiswa ne-Mn18Cr2 |

|---|---|---|---|

| Mn14Cr2 | Amandla empembelelo ephezulu, ukuxhathisa kwe-abrasion | Amatye athambileyo okanye angaxutywanga | Isiseko |

| Mn18Cr2 | Umsebenzi ogqwesileyo wokuqina, ukuxhathisa kwe-abrasion | Amatye aphakathi ukuya kunzima, angenawo | Isiseko |

| Mn22Cr2 | Ukuxhathisa okuphezulu kwe-abrasion, ubomi obude bokunxiba | Amatye anzima kunye namatye | Inde kune-Mn18Cr2 |

| Ukufakwa kwe-TIC | Ukuqina okuphezulu kakhulu, ukumelana nempembelelo | Izinto ezinzima kakhulu kunye ne-abrasive | 1.5 ukuya ku-2.5 amaxesha ubude kuno-Mn18Cr2 |

Abasebenzisi abasebenzisa imathiriyeli yesondlo esiqinileyo okanye esirhabaxa bahlala bekhetha i-Mn22Cr2 okanye i-TIC yokufaka iipleyiti zobomi obude bokunxiba kunye nexesha elincitshisiweyo lokuphumla.

Ukulungelelanisa iisetingi zeCrusher kunye noLungiselelo lokutya

Izicwangciso ezifanelekileyo zokutyumza kunye namalungiselelo okutya kunceda ukwandisa ubomi beepleyiti zemihlathi kunye neentambo. Abaqhubi basebenzisa iindlela ezininzi:

- I-in-line feeding ilungelelanisa izinto kunye nokuvulwa kwesityuli, ukunciphisa ukuvala kunye nokunxiba okungalinganiyo.

- Ukutya okukrwitshiweyo kugcina igumbi ligcwele ubuncinci be-80%, likhuthaza ukunxitywa okufanayo kunye nokutyunyuzwa okusebenzayo.

- Ukuhlolwa kwangaphambili kususa izohlwayo kunye nobukhulu bezinto eziphathekayo, ukuthintela imiqobo kunye nokunxiba okungalinganiyo.

- Ukutya okulungiselelwe kakuhle kuqinisekisa ukutya okuzinzile kwaye kunciphisa ukunxiba kwendawo.

- Ukukhawulela umxholo wesinyithi kwisondlo ukhusela amacandelo kumonakalo.

Ukulungelelanisa ukuseta kwecala elivaliweyo kwakhona kulawula i-angle ye-nip kunye nokusebenza kakuhle kokutyumza. Ukutya okuqinileyo kunye nokusetha okufanelekileyo kugcina amazinga okunxiba afanayo kunye nokuphucula ubomi obude boMshini we-Jaw Crusher.

Amaqhinga oLondolozo kunye nokuBeka iliso lokuNxitywa

Izicwangciso zokulondoloza ezisebenzayo zinciphisa ukuguga kunye nokuthintela ukungaphumeleli okungalindelekanga. Abasebenzisi baxhomekeke kwi:

- Ukugcinwa kothintelo, okubandakanya ukuhlolwa okucwangcisiweyo kunye nokutshintshwa kwenxalenye ngaphambi kokuba kwenzeke ukusilela.

- Ukugcinwa okuqikelelwayo, ukusebenzisa abenzi boluvo kunye nezixhobo zokubeka iliso ukufumanisa iimeko ezingaqhelekanga kwangoko kunye nokucwangcisa ukulungiswa kwangexesha.

- Iinkqubo zokubeka iliso eziphezulu, ezifana ne-ultrasonic sensors kunye ne-telematics, zibonelela ngedatha yexesha langempela kumanqanaba okutya kunye nesimo sezixhobo.

Abaqhubi basebenzisa ezi zicwangciso zokulandelela ukuqhubela phambili kokunxiba kunye nokulungelelanisa imisebenzi njengoko kuyimfuneko. Ukujongwa kwexesha lokwenyani kunye nokuzenzekelayo kunceda ukugcina ukuhamba kwezinto ezizinzileyo, ukunciphisa ukunxiba, kunye nokuphucula ukusebenza kwe-crusher.

Ingcebiso: Ukudibanisa ukukhusela kunye nokugcinwa kwangaphambili kunye neteknoloji yokubeka iliso yanamhlanje kukhokelela kubomi obude kunye nokuvalwa okumbalwa okungacwangciswanga.

IiNdlela eziQikelelayo zoBomi obandisiweyo

Imisebenzi yale mihla yemizi-mveliso ixhomekeke ekugcinweni kwangaphambili ukugcina oomatshini bokutyumza imihlathi besebenza ngokufanelekileyo. Iindlela zokuqikelela zisebenzisa itekhnoloji kunye nokubeka iliso rhoqo ukubona iingxaki ngaphambi kokuba zenze umonakalo. AbaSebenzi banokwandisa ubomi bamalungu emihlathi ngokulandela ezi zenzo zobulumko:

- Faka izixhobo zokujonga ubushushu beoyile yokuthambisa kunye nemeko yokucoca. Ukubona kwangethuba utshintsho kubonisa imiba enokubakho.

- Cwangcisa uhlolo lwemihla ngemihla, lweveki, nolwenyanga usebenzisa uluhlu lokukhangela oluneenkcukacha. Ukuhlolwa rhoqo kunceda ukubamba ukuguga ngaphambi kokuba kube nzima.

- Khetha iipleyiti zemihlathi ezinomxholo ophezulu wemanganese, njengeZGMn13. Ezi zixhobo zihlala ixesha elide phantsi kweemeko ezinzima.

- Qinisa iibholithi kunye namandongomane, kwaye utshatise iincopho zamazinyo kwiintlambo. Ukudityaniswa okufanelekileyo kuthintela ukunxiba okungalinganiyo kunye nokusilela kwenxalenye yokuqala.

- Yongeza izixhobo zokunciphisa ukungcangcazela kwaye ulawule izinga lokutya. La manyathelo anciphisa uxinzelelo kwi-crusher kwaye acothe ukunxiba.

Abasebenzisi abasebenzisa ulondolozo oluqikelelweyo babona ukonakaliswa okumbalwa okungalindelekanga kunye nobomi obude.

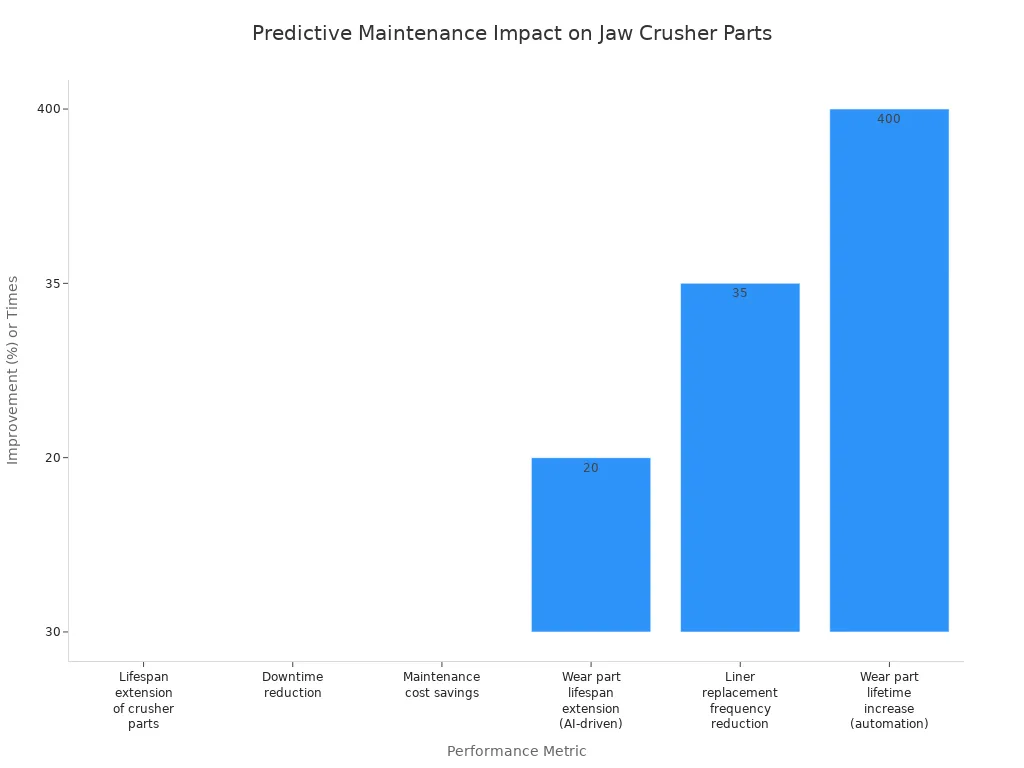

Idatha yelizwe langempela ibonisa impembelelo yezi zicwangciso. Itheyibhile engezantsi igxininisa uphuculo oluphambili ukusuka kulondolozo oluqikelelweyo:

| Umgangatho wokuSebenza | INkcukacha-manani yoPhuculo | Inkcazo yempembelelo |

|---|---|---|

| Ukwandiswa kwexesha lokuphila kweendawo zokutyumza | Ukuya kuthi ga kwi-30% | Izinto ezisemgangathweni ophezulu kunye nokunyamekela kwangaphambili kunciphisa ukutshintshwa. |

| Ukunciphisa ixesha lokuphumla | Ukuya kuthi ga kwi-30% | Izinzwa ze-Smart kunye nokufumanisa kwangaphambili zisika izitophu ezingacwangciswanga. |

| Ukongiwa kweendleko zokugcina | Ukuya kuthi ga kwi-30% | Ulondolozo olusekelwe kwiimfuno luthoba iindleko. |

| Nxiba inxalenye yobomi bolwandiso (eqhutywa yi-AI) | 15-20% | I-AI kunye ne-automation yandisa ukuqina. |

| Ukunciphisa amaza okutshintsha kwe-Liner | 35% | Izixhobo zokuqikelela zithetha utshintsho oluncinci lwelayini. |

| Ukunxiba inxalenye yobomi bonyuso (ukuzenzekela) | 2 ukuya ku-4 amaxesha | Ukuzenzela okuzenzekelayo kwandisa kakhulu inxalenye yobomi. |

Iinkqubo zokulawula i-Smart crusher, ezifana nezo zisetyenziswa kwimisebenzi ekhokelayo, ziye zanda ixesha lokunxiba nge-15-20%. Iziganeko zexesha lokuphumla zehle nge-40%, kwaye i-liner replacement frequency frequency yehla ngama-35%. Izinzwa ezilandelela iqondo lobushushu, ukungcangcazela, kunye nokunxiba kunceda abaqhubi basebenze phambi kokuba kwenzeke ukusilela. Olu tshintsho lusuka ekubeni lusebenze ukuya kulungiso oluqikelelweyo lugcina oomatshini besebenza ixesha elide kwaye konga imali. Iindlela eziqikelelwayo zinika abaqhubi ulawulo olungakumbi kunye nokuzithemba ekusebenzeni kwabo kwesityuli somhlathi.

IiNgcebiso eziGqwesileyo zokuSebenzisa uMtshini weMihlathi weMihlathi iNdawo yobomi

Ukutshatisa iPlate yeJaw Material ukuFundisa iimpawu

Ukukhetha ipleyiti yomhlathi ekunene kunye noyilo kubalulekile ekwandiseni inxalenye ubomi isityumzi. Abasebenzisi kufuneka:

- Khetha i-alloys yepleyiti yomhlathi ngokusekelwe kwi-abrasiveness. I-alloy ye-M1 isebenza kakuhle kwizinto ezi-low-abrasion ezifana ne-limestone. Ii-alloys eziphambili ezifana ne-M2, M7, M8, okanye i-M9 zibhetele kwizinto ezirhabaxa kakhulu njengegranite okanye intsimbi ekrwada.

- Tshatisa iipateni zamazinyo kwifidi. Amazinyo Abanzi (WT) anceda ngokutya okuphezulu kwisohlwayo ngokuthintela ukupakisha. Amazinyo abukhali (ST) abamba iflokhwe okanye i-angular, enciphisa ukutyibilika. I-Corrugated Corrugated (CC), i-Heavy Duty (HD), okanye i-Ultra-Thick (UT) iipleyiti ezimelana nokutya okukrakra.

- Landela iingcebiso imodeli isityumzi. Umzekelo, iipleyiti ze-CJ615 zihlala zisebenzisa i-Coarse Corrugated okanye iipleyiti ze-Heavy Duty kunye ne-M8 alloy kwi-abrasive feed.

- Jikelezisa iipleyiti zemihlathi ngexesha lomjikelo wabo wobomi ukuqinisekisa ukuba zinxitywe kwaye ugcine eyona angle nip ilungileyo.

- Lungisa useto lwesityumzi, olufana nokusetwa kwecala elivaliweyo kunye ne-nip angle, ukutshatisa iipropati zesondlo.

Ukuthelekisa izinto zepleyiti yomhlathi kunye noyilo lokutyisa iimpawu kunceda ukwandisa ukusebenza kunye nokwandisa ubomi benxalenye.

Ukuhlolwa rhoqo kunye nokutshintshwa kwangexesha

Ukuhlolwa okuqhelekileyo kunye nokutshintshwa ngokukhawuleza kwamalungu agugileyo kugcina izityuli zisebenza ngokufanelekileyo. Abaqhubi bayaxhamla koku:

- Ukubona kwangethuba ukunxiba kunye nomonakalo ngokujongwa rhoqo kweeplate zemihlathi, iibheringi kunye namanye amacandelo.

- Ukutshintshwa kwangexesha kwamalungu agugileyo, okuthintela umonakalo ongakumbi kunye nokugcina ukusebenza kakuhle kokutyumza.

- Ukuthambisa okufanelekileyo kwamalungu ashukumayo, ukunciphisa ukungqubana kunye nokwandisa ubomi bomatshini.

- Iinkqubo zokubeka iliso ezilumkisa abaqhubi kwimiba, ukuxhasa ukulungiswa kwangaphambili kunye nokunciphisa iindleko zokulungisa.

Ishedyuli yolondolozo engaguqukiyo, kubandakanywa ukuhlolwa kunye nokutshintshwa kwenxalenye ngexesha, kwandisa ixesha lokuphumla kwezixhobo kunye nokunciphisa iindleko zokusebenza.

UQeqesho lomSebenzi kunye nokuPhuculwa kweNkqubo

Abaqhubi abaqeqeshwe kakuhle kunye neenkqubo eziphuculweyo zidlala indima ebalulekileyo ekunciphiseni ukunxiba. Abasebenzisi kufuneka:

- Sebenzisa udidi lwesondlo olululo kunye nokulawula izinga lokutya ukunyusa umthamo kunye nokunciphisa ukuguga.

- Lungisa useto lwesityumzi, olufana nesetingi yecala elivaliweyo, usebenzisa iishim kunye nobude bokuguqula ukubuyisela ukunxitywa.

- Linganisa umsantsa phakathi kwemihlathi ukuqinisekisa useto oluchanekileyo.

- Yenza uhlengahlengiso kuphela xa i-crusher ingenanto kwaye uyeka ukuphepha ukunxiba kwangaphambi kwexesha.

- Thembela kwiinkqubo zokuthambisa ezizenzekelayo zokuthambisa ngokuhambelana nokuzala.

- Qonda ubuchule bokutyisa kunye neenkqubo zokulondoloza ukunciphisa ukunxiba kunye nokwandisa ubomi bomatshini.

Uqeqesho lomsebenzisi kunye nokulungiswa kwenkqubo kuqinisekisa ukusebenza okuthembekileyo kunye nokwandisa ubomi beendawo zokutyumza.

Iipropathi zezinto zokutya ziqhuba amazinga okunxiba kunye nobomi benkonzoiindawo zokutyumzakwiindawo zoshishino. Abasebenzisi abasebenzisa ukubekwa esweni okukhawulezileyo, bakhethe izinto ezingagugiyo, kwaye bahlengahlengise imisebenzi banokwandisa ubomi benxalenye ukuya kuthi ga kwi-50% kwaye banciphise iindleko zolondolozo. Imilinganiselo yemizi-mveliso ibonisa ukuba ezona ndlela zingcono zithoba iindleko zokusebenza nge-10% ukuya kuma-20% kwaye zandise ubomi besixhobo nge-15%. Olu phuculo lukhokelela kwimveliso ephezulu kunye nembuyekezo eyomeleleyo kutyalo-mali.

FAQ

Yeyiphi ipropathi yezinto zokutya ebangela eyona pleyiti yomhlathi ikhawulezayo ukunxiba?

Ukuqina kunye nokuqina kubangela ukunxiba ngokukhawuleza. Amatye aqinileyo njengegranite okanye iiminerali ezinequartz zisila ngokuchasene neepleyiti zemihlathi. Abaqhubi babona ukutshintshwa rhoqo xa kusenziwa ezi mathiriyeli.

Ngaba ukufuma kwizinto zokutya kuchaphazela njani iindawo zokutyumza imihlathi?

Ukufuma kunokukhokelela ekuvalelekeni nasekunxibeni okungalinganiyo. Izinto ezincangathi, ngakumbi ngodongwe, zakha ngaphakathi kwisityuli. Oku kwakha kwandisa uxinzelelo kwiindawo kwaye kunokubangela ukuguga ngokukhawuleza.

Ngaba abaqhubi banokunciphisa ukuguga ngokulungisa ubungakanani besondlo?

Ewe. Abaqhubi abalawula ubungakanani bokutya kunye nokususa amatye amakhulu okanye iifayini zinceda ukusabalalisa ukunxiba ngokulinganayo. Esi senzo sandisa ubomi bepleyiti yomhlathi kwaye siphucula ukusebenza kakuhle kwesityumzi.

Yeyiphi imathiriyeli yepleyiti yomhlathi esebenza ngcono kwisondlo esirhabaxa?

Intsimbi yeManganesengechromium ephezulu okanye i-TIC efakelwayo ixhathisa i-abrasive wear best. Ezi zixhobo zibamba amatye anzima kunye namatye, anikezela ubomi obude benkonzo.

Kufuneka abaqhubi bahlole kangaphi indawo ezinxitywayo zesityuli semihlathi?

Abaqhubi kufunekahlola iindawo zokunxibangeveki. Ukuhlolwa rhoqo kunceda ukubona iimpawu zomonakalo kwangethuba. Ukutshintshwa ngexesha elifanelekileyo kuthintela ukuphuka okungalindelekanga kwaye kugcina isityuli sisebenza kakuhle.

Ixesha lokuposa: Jul-17-2025