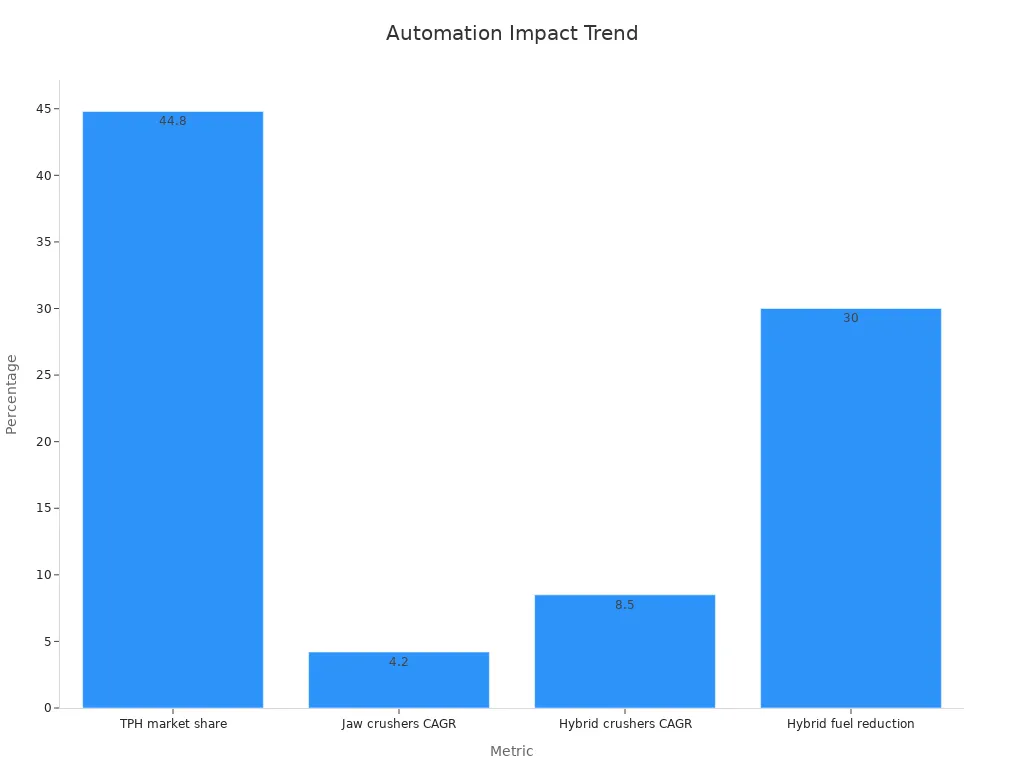

Itekhnoloji yezahlulo zeCrusher igcina ukutyhala imida ngo-2025. Ngokomzekelo, ukujonga ixesha lokwenyani kunye neenkqubo ze-hybridi zinceda ukunciphisa ixesha lokunciphisa kunye nokunciphisa ukusetyenziswa kwamandla ukuya kuthi ga kwi-30%.

| Umetriki/uMgangatho | Ixabiso/uBalo | Impembelelo kuMsebenzi weCrusher ngo-2025 |

|---|---|---|

| Ingeniso yokutyumza imihlathi enye (2024) | I-USD 1.8 yezigidigidi | Ukongamela kwimarike yoyilo oluphambili |

| 100–300 TPH isabelo secandelo lomthamo (2024) | 44.8% | Ukusebenza kakuhle kwamafutha kunye nokuzenzekelayo |

| Izityumzi zeHybrid ziqikelele kwi-CAGR | 8.5% | Ukuphucula ukusebenza kakuhle kwamandla |

Abaqhubi babona inzuzo yokwenene kunye nobomi benkonzo obude beiindawo zokunxiba i-crusher, iindleko ezisezantsi koomatshini emhlathini isityumzi, kunye neenketho bhetyebhetye ngenxaiindawo zokutyumza ikhoni, impembelelo iindawo zokutyumza, kwayeVSI iindawo zokutyumza.

Izinto eziphambili zokuThatha

- Iinzwa ze-Smart kunye ne-automation inceda ukubona iingxaki kwangoko,ukunciphisa ixesha lokuphumla, kwaye wonge imali kwisondlo.

- Izinto eziphezulu kunye neengubo zokugqokayenza iindawo zokutyumza zihlale ixesha elide, zisebenze ngcono, kwaye ziphantsi iindleko zokubuyisela.

- Uyilo oluwonga amandla kunye nolawulo oluguquguqukayo lwesantya lunciphisa ukusetyenziswa kwamandla kunye nokunciphisa iindleko zokusebenza.

- Iinxalenye zeModyuli kunye nezihambayo zivumela ukulungiswa ngokukhawuleza, ukuphucula ukhuseleko, kunye nokubonelela ngezisombululo eziguquguqukayo zemisebenzi eyahlukeneyo.

- I-AI kunye nezixhobo zedijithali zixela kwangaphambili ukungaphumeleli, ukwandisa ukusebenza kakuhle, kunye nokwandisa ubomi bezixhobo, ukunyusa imveliso kunye nokunciphisa iindleko.

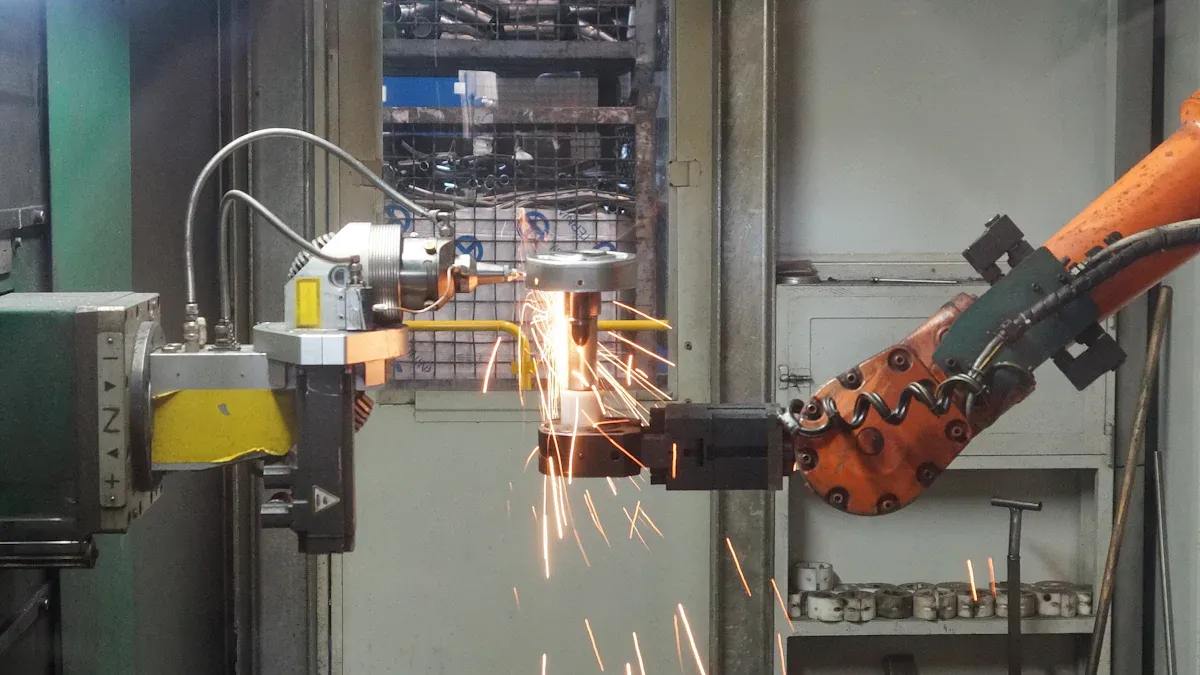

I-Smart sensors kunye ne-Automation kwi-Crusher Parts

Ukubeka iliso ngexesha lokwenyani kunye noLondolozo oluqikelelweyo

Izinzwa ezihlakaniphile ngoku zidlala indima enkulu ekugcineniiindawo zokutyumzaihamba kakuhle. Ezi zoluvo ukulandelela impilo izixhobo ngexesha lokwenyani. Abasebenzisi bafumana uhlaziyo oluphilayo malunga nobushushu, ukungcangcazela, kunye nokunxiba. Oku kubanceda babone iingxaki ngaphambi kokuba bajike babe ziintsilelo ezinkulu. Iinkqubo zogcino oluqikelelweyo zisebenzisa uhlalutyo lwedatha ukufumana iimpazamo kwangethuba. Oku kuthetha ukuba amaqela angalungisa imiba ngaphambi kokuba abangele ixesha lokuphumla.

- Iinkqubo zokuthambisa ezizenzekelayo zicwangcisa imijikelo yokuthambisa esekelwe kwidatha yexesha langempela, enceda ukuthintela ukusilela ekuthwaleni.

- Izinzwa zokujonga imeko zinika uhlaziyo oluphilayo, ukuze abaqhubi basebenze ngokukhawuleza.

- Ulondolozo oluqikelelweyo lutshintsha ukulungiswa ukusuka kwishedyuli emiselweyo ukuya kwindlela esekelwe kwiimfuno, ukonga ixesha kunye nemali.

- Ukujongwa kwexesha lokwenyani kunye nezakhelo zamawele edijithali ziqikelela ukunxiba kwesixhobo, ukunciphisa ukonakaliswa okungalindelekanga.

- Iimodeli zokufunda ezinzulu zinokuqikelela ukunxiba kwesixhobo ngokuchaneka okuphezulu, ukwenza ulondolozo lube nobuchule.

Ezi zixhobo zihlakaniphile zinceda iinkampani ukuba zandise ubomi bezixhobo kwaye zinciphise iindleko zokulondoloza.

Iinkqubo zoLungiso oluzenzekelayo lwezahlulo zeCrusher

Ukuzenzekela akuyeki ekubekeni iliso. Izityumli ezininzi zanamhlanje zisebenzisa iinkqubo zokuhlengahlengisa ezizenzekelayo. Ezi nkqubo zitshintsha izicwangciso ezifana nobubanzi besithuba okanye izinga lokutya ngaphandle kokumisa umatshini. Abasebenzisi banokwenza utshintsho kwiphaneli yolawulo okanye nokuba kude. Oku kugcina isityumzi sisebenza ngeyona ndlela ingcono kwaye kunciphisa imfuno yokuhlolwa kwesandla.

- I-Powerscreen Pulse, umzekelo, inika ulwazi lwexesha lokwenyani kwimeko yomatshini, ukunxiba, kunye neemfuno zokulondolozwa.

- Iimpawu ezifana ne-GPS ephilayo, ukusebenza kakuhle kwamafutha, kunye nemiyalezo yempazamo inceda abaqhubi ukuba benze izigqibo ezikhawulezayo.

- Ukufikelela ukude kuthetha ukuba amaqela angabeka iliso kwaye ahlengahlengise iisetingi naphi na.

Isifundo esingumzekelo: UkuNcitshiswa kwexesha lokuSebenza kunye nezahlulo ze-Smart Crusher

Iziphumo zehlabathi lokwenyani zibonisa amandla e-automation smart. Izilumkiso zogcino oluqikelelweyo kumatshini weCaterpillar zinciphisa ixesha lokuncipha ngama-30%. Iinkampani zibone ukonyuka kwe-20% ekusebenzeni ngokufanelekileyo kwaye zonga ukuya kuthi ga kwi-500,000 yeedola ngonyaka. Iideshibhodi zexesha lokwenyani zincede isicwangciso sokulungisa nokugcina oomatshini besebenza ixesha elide.

Iinzwa ze-Smart kunye ne-automationnceda abaqhubi baphephe ukophuka kweendleko kwaye bagcine iinxalenye zesityuli zisebenza nzima ixesha elide.

IziXhobo eziNxibeleleyo zokuNxibelela kwizahlulo zeCrusher

Ii-alloys zesizukulwana esilandelayo kunye neeComposites

Ii-alloys ezintsha kunye ne-composites ziyatshintsha ukuba iinxalenye ze-crusher zihlala ixesha elide kangakanani. I-Metal Matrix Composites (MMC) ibalasele kuba inokuhlala kude kube ngokuphindwe kathathu kuneemathiriyeli ezindala. Amanye amalungu, njenge-Rock Box spider arm liner, ngoku anikezela ukuya kuma-300% ngaphezulu kokunxiba ubomi. Oku kuthetha ukuba ixesha lokuphumla lincinci kunye nokutshintshwa okumbalwa.Iiracks zokufakwa kwe-concave eziphambilikwakhona kunceda ngokusika ixesha lokufakela kwisiqingatha, okwenza ukugcinwa kukhuseleke kwaye ngokukhawuleza. Iinjineli zisebenzisa i3D laser scanning ukulandelela ukunxiba kunye nokwandisa imilo yamagumbi okutyumza. Oku kunokuphinda kabini ubomi bokunxiba kwezinye iindawo. Olu phuculo lwenza iindawo zokutyumza zomelele, zikhuseleke, kwaye zithembeke ngakumbi.

- Uvavanyo lokugqoka intsimi lubeka izixhobo kwiimeko zangempela zemigodi, zinika iziphumo zangempela zehlabathi.

- Ii-alloys ezahlukeneyo, njengeentsimbi zekhabhoni kunye nentsimbi emhlophe, zibonisa umahluko omkhulu kwindlela ezixhathisa ngayo ukunxiba.

- Izixhobo ezingcono zithetha iindleko eziphantsi zokutshintshwa, abasebenzi, kunye nokulahleka kwemveliso.

- Imodeli yekhompyuter inceda oosonzululwazi bayile izixhobo eziqine ngakumbi ngokufunda amandla abo kunye nendlela ezaphuka ngayo.

Iingubo zeCeramic kunye nePolymer kwiiNdawo zeCrusher

Iingubo zeCeramic kunye ne-polymer zongeza enye ingqimba yokukhusela. Ezi zogquma zinceda amalungu e-crusher ukuba axhathise imikrwelo, ubushushu kunye nomhlwa. Iingubo zeCeramic zinzima kakhulu kwaye ziyakwazi ukusingatha imisebenzi enzima, ngelixa iingubo ze-polymer zilula kwaye zinciphisa ukukhuhlana. Ngokudibeneyo, bancedisa iindawo zokutyumza ukuba zihlale ixesha elide kwaye zisebenze ngcono. Ezinye iileyiti ezintsha zide zincede ukonga amandla ngokunciphisa amandla afunekayo okuqhekeza amatye. Oku kuthetha ukuba oomatshini basebenzisa amandla amancinci kwaye bahlala kwinkonzo ixesha elide.

- Umvavanyi okhethekileyo womhlathi wemihlathi ubonisa ukuba ukunxiba kunye nokusetyenziswa kwamandla kunxulumene ngokusondeleyo.

- Ukunxiba okuncinci kuthetha ukuchithwa kwamandla amancinci, ngoko ke izityuli zisebenza ngokufanelekileyo.

Traditional vs. Advanced Crusher Parts Materials

| Metric | I-Advanced Crusher Liners (umzekelo, iBanga lama-846 lentsimbi yemanganese) | IiLiner zemveli/zoMgangatho oPhantsi |

|---|---|---|

| Nxiba Ubomi | Malunga ne-2x ubude | Isiseko |

| Ukutyumza Ukusebenza | 35% ngcono | Isiseko |

| UPhuculo lokuSebenza | Ewe | No |

| UkuNcitshiswa koMzobo waMandla | Ewe | No |

| Izixhobo ezisebenzayo | Ewe | No |

Izinto eziphambili ezifana neBanga le-846 lentsimbi ye-manganese ine-manganese eninzi kunye nekhabhoni. Olu lungelelwano lubanika ubunzima obungcono kunye nokuqina. Izinto zemveli azihlali ixesha elide kwaye zifuna ukutshintshwa rhoqo. Ezinye izinto ezidityanisiweyo eziphambili, njenge-carbon fiber-reinforced polymer, zomelele kakhulu kodwa zinokuba brittle kwaye zibize ngaphezulu. Okwangoku, ukuxuba isinyithi kunye ne-composites kunika iziphumo ezilungileyo kakhulu kwiindawo zokutyumza.

Ukukhetha izixhobo ezixhathisayo zokunxiba kunceda iinkampani zonge imali, zinciphise ixesha lokuphumla, kwaye zifumane ngakumbi kwiindawo zazo zokutyumza.

Izinto ezintsha zokuSebenza kwamandla kwiiNdawo zeCrusher

Amandla okugcina iiNdawo zeCrusher zoyilo

Abavelisi ngoku bayilaiindawo zokutyumzaukugcina amandla amaninzi kunangaphambili. Izityumza zecone zanamhlanje zisebenzisa izinto ezinje ngeedrive eziguquguqukayo. Ezi drives zilungelelanisa isantya esekelwe ukuba zingakanani izinto ezifuna ukutyunyuzwa. Olu hlengahlengiso lunobulumko lunokonga malunga ne-20% ekusebenziseni amandla. Olunye uyilo olutsha lude lusebenzise iibheringi zemagnethi. Ezi bheringi zinciphisa ukusetyenziswa kwamandla ukuya kutsho kuma-30% kwaye amalungu anceda ukuba ahlale ixesha elide. Xa iinkampani zikhetha isityuli esifanelekileyo somsebenzi, ziphepha ukuchitha amandla. Ukugcina ubungakanani besondlo buzinzileyo kunye nokusebenzisa iindawo ezikumgangatho ophezulu nako kuyanceda. Ukuhlolwa rhoqo kwimivalo yempembelelo, iilayini, kunye namabhanti agcina yonke into ihamba kakuhle kwaye ngokufanelekileyo.

Ingcebiso: Ukusebenzisa i-hybrid okanye izityumli zombane ezine-smart automation zinokuthoba amafutha kunye namatyala ombane ngakumbi.

Ukuqhuba ngesantya esiguquguqukayo kunye noLawulo kwiiNdawo zeCrusher

Iidrive zesantya eziguquguqukayo (VSDs) kunye neenkqubo zolawulo zenza umahluko omkhulu kwindlela izityuzi zisebenza ngayo. Ii-VSD zivumela abaqhubi balawule isantya seenjini ngokuchaneka okukhulu. Oku kuthetha ukuba i-crusher isebenzisa kuphela amandla amaninzi njengoko ifuna. Xa umatshini uqalisa, ii-VSD zinciphisa ukungxama kombane, nto leyo ekhusela i-motor kwaye igcina amandla. Ezi drives zikwanceda ekunciphiseni ukuguga kwamalungu kunye nokunciphisa inkunkuma. Ngokudibanisa ii-VSDs kwiinkqubo zokulawula ezihlakaniphile, amaqela anokubukela ukusetyenziswa kwamandla ngexesha lokwenyani kwaye abone naziphi na iingxaki ngokukhawuleza. Oku kugcina isixhobo sokutyumza sisebenza kakuhle kwaye kunceda ukuphepha ukulungiswa okuxabisa kakhulu.

IiMpembelelo zeNdleko zokuSebenza zezahlulo zeCrusher eziSebenza kakuhle

Iindawo zokutyumza ezonga amandla zinceda iinkampani zonge imali yonke imihla. Kwi-Clarabelle Mill, ukusebenzisa izixhobo zokutyumza ngomthamo opheleleyo wokuyilwa kwehlise ukusetyenziswa kwamandla kwaye kwehlise iindleko zombane. Xa izixhobo zisebenza kangangoko, kukho izohlwayo zamandla ezimbalwa. Iinkampani ezisebenzisa ukulungiswa kwangaphambili zichitha i-20-30% ngaphantsi ekulungiseni. Bakwabona ukonyuka kwe-10-20% kwindlela abafumaneka ngayo oomatshini babo. Uluhlu olungezantsi lubonisa indlela iindlela ezahlukeneyo zokonga iindleko ezisebenza ngayo:

| Indlela yokuHlalutya iindleko | Inkcazo |

|---|---|

| Uhlalutyo lweendleko zoBomi | Ujonga zonke iindleko kubomi bezixhobo, kubandakanya amandla kunye nokulungiswa. |

| Iindleko zizonke zobunini | Yongeza iindleko ezizinzileyo kunye neziguquguqukayo ukubona ukonga ixesha elide. |

| Ugcino oluqikelelweyo | Ukunciphisa iindleko zokulungisa ukuya kuthi ga kwi-30%. |

| ULondolozo oluLungileyo | Yandisa ukusetyenziswa kwezixhobo kwaye konga imali eninzi. |

Ukukhetha iindawo zokutyumza ezonga amandla kukhokelela kumatyala aphantsi, ixesha lokuphumla elisezantsi, kunye nokusebenza ngcono.

IiModyuli kunye neMobile Crusher Parts Solutions

Utshintsho olukhawulezayo lwezahlulo zeModyuli zeCrusher

Iinkqubo zeemodyuli zokutshintsha ngokukhawuleza zitshintshile indlela amaqela aphatha ngayoukugcinwa kwesityuli. Ezi nkqubo zivumela abasebenzi ukuba batshintshe iindawo ezigugileyo ngokukhawuleza, rhoqo ngaphandle kwezixhobo ezikhethekileyo. Uyilo lwemodyuli luthetha ukuba amaqela anokuxuba kwaye atshatise izityuli, izikrini, kunye nabahambisi ukuze balingane nomsebenzi ngamnye. Oku kuguquguquka kunceda iinkampani ukuba zijongane nezixhobo ezahlukeneyo kunye neemfuno zesiza ngokulula. Amagumbi okutyumza akumgangatho ophezulu anyusa imveliso kunye nokusika iibhotile. Ukuzenzekela kunye nokujongwa kude, njengePulse telematics, kugcina oomatshini besebenza ixesha elide ngokulumkisa amaqela kwimiba ngaphambi kokuba ibe yingxaki.

- Amalungu emodyuli anciphisa ixesha lokuphumla ngexesha lokulungiswa.

- Amaqela angenza ngokwezifiso ukuseta kwiprojekthi nganye.

- Ukhuseleko luyaphucuka kuba abasebenzi bachitha ixesha elincinci bephethe iinxalenye ezinzima.

Ingcebiso: Iinkqubo zemodyuli zikwaxhasa iiyunithi zamandla asebenzayo, ukunceda iinkampani ukuba zihlangabezane nemigangatho yokukhutshwa kunye neenjongo zokuzinza.

Izahlulo ze-Mobile Crusher zeMisebenzi eguquguqukayo

Iindawo zokutyumza eziphathwayo zizisa inqanaba elitsha lokuguquguquka kwiindawo zemisebenzi. Ezi ndawo ziza zixhonywe kwi-chassis enamavili okanye elandelwayo, ukuze amaqela angazisusa ngokukhawuleza ukusuka kwesinye isiza ukuya kwesinye. Izityumli ezihambayo zihlala ziqala ukusebenza kwimizuzu engama-30 ukuya kwiiyure ezimbalwa emva kokufika. Oku kuthunyelwa ngokukhawuleza konga ixesha kunye nemali. Ukutyunyuzwa kwindawo kuthetha ukuthotywa kancinci kwemathiriyeli ekrwada, nto leyo ethoba iindleko zothutho kunye nongcoliseko. Izityumli eziphathwayo zibamba uluhlu olubanzi lwemathiriyeli, ukusuka emigodini ukuya ekusetyenzisweni ngokutsha, kwaye zilungelelanise nokutshintsha kweemeko zesiza.

| Uphawu | Mobile Crusher | Isityuli esisisigxina |

|---|---|---|

| Ukushukuma | Ihamba ngokulula phakathi kweesayithi | Ilungiswe kwindawo enye |

| Ixesha lokusasaza | Imizuzu engama-30 ukuya kwiiyure | Ukuseta ixesha elide kuyadingeka |

| Umthamo | 225-1000 iitoni / ngeyure | Ukuya kuthi ga kwi-2000+ yeetoni/ngeyure |

| Ukuba bhetyebhetye | Phezulu | Phantsi |

| Iindleko zoLondolozo | Phezulu | Ngasezantsi |

| Impembelelo yokusingqongileyo | Kufuneka isithuthi esincinci | Ifuna ulawulo lothuli |

| Umsebenzi wobomi | Mfutshane | Ixesha elide |

Izityumli eziphathwayo zisebenzisai-rotor yemodyuli kunye neenkqubo zesixhobo. Amaqela anokuzilungelelanisa ezi zixhobo ezahlukeneyo, eziphucula ukusebenza kakuhle kunye nokwandisa ubomi benxalenye yokunxiba.

UkuNcitshiswa kwexesha loLondolozo kunye nezahlulo zeModyuli zeCrusher

iindawo zokutyumza iimodyuli zenza ulondolozo ngokukhawuleza kakhulu. Amaqela akuseyomfuneko ukuba achithe iiyure okanye iintsuku elungisa. Iinkqubo zokutshintsha ngokukhawuleza zivumela abasebenzi ukuba bathathe indawo yamalungu agugileyo ngexesha elincinci, nto leyo egcina oomatshini besebenza. Le ndlela ikwanciphisa ukuphatha ngesandla, ukwenza inkqubo ikhuseleke kwaye ibe lula. Iinkampani zibona ixesha eliphantsi lokuphumla kunye neendleko eziphantsi zabasebenzi. Amaqela oncedo oluzenzekelayo kunye nokubek' esweni okude acwangcise ulungiso phambi kokuba ukonakala kwenzeke.

- Ukutshintsha kwenxalenye ekhawulezileyo kuthetha ixesha elongezelelweyo.

- Umsebenzi omncinci wezandla uphucula ukhuseleko kunye ne-ergonomics.

- Ukusetyenzwa kwisiza kunciphisa ukulibaziseka kwezothutho kunye nokulungiswa.

Iinkampani ezisebenzisa izisombululo zemodyuli kunye neselfowuni zibona iinzuzo zokwenyani kwimveliso, ukhuseleko, kunye nokonga iindleko.

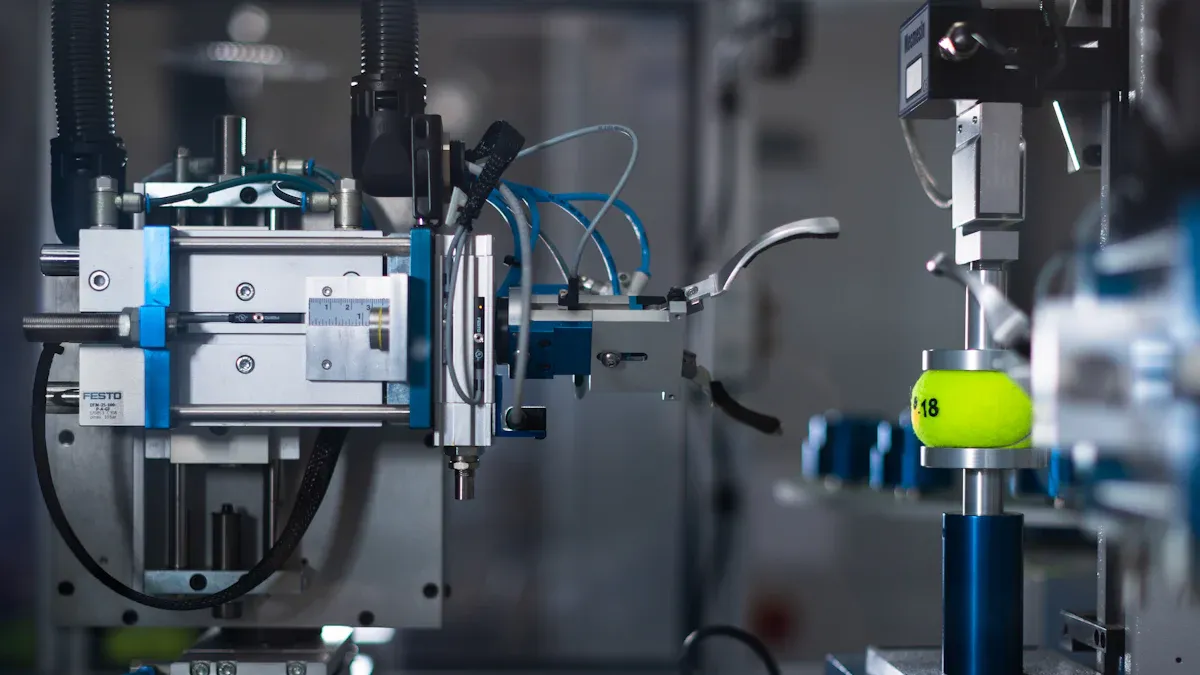

Ukwenziwa kweDijithali kunye noLondolozo oluQhelekileyo lwezahlulo zeCrusher

Uhlalutyo lweDatha yoKusebenza kwaMacandelo eCrusher

Uhlalutyo lwedatha ngoku lunceda iinkampani ukuba zifumane okuninzi kwizixhobo zazo. Ngokusebenzisa izixhobo zedijithali, amaqela anokulandelela ukuba abaqhubi basebenza njani ngexesha lokwenyani. Uyilo lweeMvavanyo (DoE) luvumela iinjineli ukuba zivavanye izicwangciso ezahlukeneyo kwaye zibone ukuba utshintsho luchaphazela njani imveliso. Bayakwazi ukubona iipateni eziphoswe ziindlela zakudala. Ngokomzekelo, banokubona indlela isantya kunye nobukhulu be-gap basebenzisana ngayo ukutshintsha ukusebenza. Amaqela asebenzisa isampula yokusikwa kwebhanti kunye nokubeka iliso kwinkqubo ukuqokelela idatha. Oku kubanceda bahlengahlengise oomatshini ukuze bafumane iziphumo ezingcono. Imifuniselo yedijithali yenza kube lula ukucwangcisa nokuphucula imveliso.

- Iinjineli zisebenzisa iequation zolandelelwano lokuqala kunye neyesibini ukulinganisa ukusebenza kwesityum.

- Ukubeka iliso okuqhubekayo kunceda amaqela ahlangabezane nemigangatho yemveliso kunye neemfuno zemarike.

IiPlatifomu zokuGcinwa kweNgcaciso yeeNdawo zeCrusher

Amaqonga olondolozo aqikelelweyo asebenzisa idatha yexesha langempela ukugcina oomatshini besebenza ixesha elide. I-Nukon yakhe ideshbhodi ye-Newcrest Mining eqikelela ukuba mayifakwe nini endaweni yayoiilayini. Esi sixhobo sisebenzisa idatha ephilayo kunye neemodeli zokubuyisela ukucwangcisa ukugcinwa. Amaqela awasaqikelela ukuba alungise nini na amalungu. Bafumana izilumkiso ngaphambi kokuba iingxaki zenzeke. Le ndlela ithatha indawo yeendlela zakudala, ezenziwe ngesandla kwaye yenza ukucwangcisa kube lula. Isiphumo sisicwangciso esingcono kunye nezityuli ezithembekileyo.

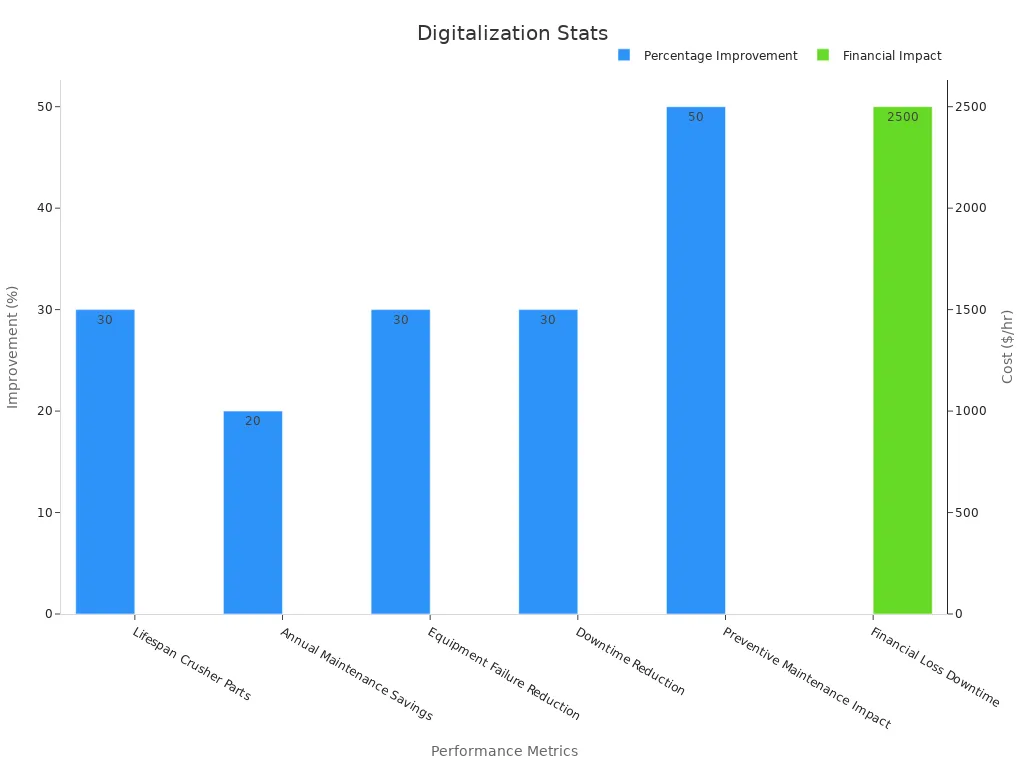

| Umgangatho wokuSebenza | INkcukacha-manani yoPhuculo | Inkcazo yempembelelo |

|---|---|---|

| Ukwandiswa kwexesha lokuphila kweendawo zokutyumza | Ukuya kuthi ga kwi-30% | Ukusebenzisa izixhobo ezikumgangatho ophezulu kwandisa ixesha lokuphila, kunciphisa ukuphindaphindeka kokutshintshwa. |

| Ukongiwa kweendleko zolondolozo ngonyaka | Ukuya kuma-20% | Izahlulo zeprimiyamu kunye nolondolozo oluphuculweyo lunciphisa iindleko zonyaka zolondolozo. |

| Ukuncitshiswa kokusilela kwezixhobo zokusebenza | Ukuya kuthi ga kwi-30% | Ukugcinwa kothintelo kunciphisa umngcipheko wokungaphumeleli, ukwandisa ukusebenza kakuhle. |

| Ukunciphisa ixesha lokuphumla | Ukuya kuthi ga kwi-30% | Utyalo-mali kwiinxalenye zeprimiyamu kunciphisa ixesha lokuphumla elingacwangciswanga kakhulu. |

| Ilahleko yemali evela kwixesha elingacwangciswanga | Malunga. $2,500 ngeyure | Igxininisa impembelelo yeendleko zexesha lokuphumla, igxininisa ixabiso lexesha eliphuculweyo. |

| Impembelelo yolondolozo oluthintelwayo ekusileleni | Ukuya kuthi ga kwi-50% yokunciphisa | Ukugcinwa okucwangcisiweyo kukunciphisa ukusilela komatshini, ukuphucula ukuthembeka kunye nexesha lokuphumla. |

Ugcino oluqikelelweyo lunceda amaqela aphephe ukophuka okuxabisa kakhulu kwaye agcine izityumli zisebenza ngokusemandleni azo.

Ukwandiswa kwaMacandelo e-Crusher Lifespan kunye neZixhobo zeDijithali

Izixhobo zedijithali zinceda ukwandisa ubomi beendawo zokutyumza. Isoftware yogcino ithumela izikhumbuzo kunye neerekhodi zokugcina. Oku kugcina uhlolo kwishedyuli kwaye kunceda amaqela ukulungisa iingxaki kwangoko. Izivamvo zokungcangcazela kunye neqondo lobushushu zibona iibholithi ezikhululekileyo okanye ukufudumeza ngokugqithiseleyo ngaphambi kokuba kwenzeke ukusilela. Iinkqubo zokuthambisa ezizenzekelayo zihambisa umlinganiselo ofanelekileyo wegrisi, zimisa ukuya kuthi ga kwi-75% yokungaphumeleli kokuthwala. Ezi zixhobo zicutha ixesha lokunciphisa ukuya kuthi ga kwi-30% kwaye zithobe iindleko zolondolozo nge-30%. Ukusebenza ngokucothayo kunokunyuka nge-15% xa amaqela asebenzisa izixhobo zedijithali ukujonga rhoqo. Iinkampani zibona ubomi obude bezixhobo kunye nezinto ezothusayo ezimbalwa.

Ukwenziwa kwedijithali kunika abaqhubi ulawulo olungakumbi, konga imali, kwaye kugcine izityumza zisebenza ixesha elide.

Ii-Eco-Friendly and Sustainable Crusher Parts Practices

Izincedisi zezahlulo eziphinda zisetyenziswe kunye nezinempembelelo ephantsi

Iinkampani ezininzi ngoku zikhethaizinto ezixhasa imigaqo ye-3R: Nciphisa, Sebenzisa kwakhona, kwaye usetyenziswe ngokutsha. Bayila iindawo zokutyumza ukuze zihlale ixesha elide kwaye ziphinde zisetyenziswe kwakhona ekupheleni kobomi babo. Kwishishini lentsimbi, iteknoloji entsha ye-slag crusher inceda ukuguqula inkunkuma ibe yimithombo exabisekileyo. Le ndlela inciphisa inkunkuma yokulahla inkunkuma kwaye ixhasa uqoqosho olujikelezayo. Uhlalutyo lwe-Lifecycle lubonisa ukuba ukusebenzisa izinto ezisetyenzisiweyo, njengekhonkrithi evela kwinkunkuma yokwakha, yehlisa i-carbon footprint. Ezi zenzo zikwanciphisa imfuno yezixhobo ezintsha, ezinceda ukukhusela ubutyebi bendalo. Amaqela agxile ekusetyenzisweni kwakhona kunye nobomi obude bemveliso abona inkunkuma encinci kunye neendleko eziphantsi.

Ukwenziwa koMbane ngokuSebenzayo kwezahlulo zeCrusher

Imveliso eyonga amandla iyayitshintsha indlela iinxalenye zecrusher ezenziwe ngayo. Iinkampani zisebenzisa i-automation kunye nolawulo oluhlakaniphile ukusika ukusetyenziswa kwamandla ngexesha lemveliso. Nazi iinyani eziphambili:

- Ukusetyenziswa kwamandla athile kuluhlu lokutyumza ukusuka kwi-0.48 ukuya kwi-1.32 kWh ngetoni nganye.

- Ukulungiswa kokutya kunye nokuzenzekelayo kunokunciphisa ukusetyenziswa kwamandla nge-10-30%.

- Uyilo olutsha kunye neengubo zokwaleka zinceda ukunciphisa ukukhuhlana, konga amandla angakumbi.

- Ukruthakruthwano kunye nokunxila kubangela ilahleko enkulu yamandla, kodwa ubugcisa obutsha bunokuphungula oku ukuya kutsho kuma-30% kwiminyaka engama-20 ezayo.

- Olu tshintsho lunokonga ukuya kutsho kwi-550 TWh yamandla kwaye lunciphise i-290 yezigidi zeetoni zeCO2 ngonyaka.

Ngokwenza iindawo zokutyumza ngamandla amancinci, iinkampani zinceda iplanethi kwaye zigcine imali.

Ukuthotyelwa kokusiNgqongileyo kwiCrusher Parts Technology

Itekhnoloji yale mihla yesityumzi inceda iinkampani ukuba zihlangabezane nemithetho engqongqo yokusingqongileyo. Nantsi indlela:

- Izityuli ngoku zinciphisa umthamo wenkunkuma, zenza kube lula ukurisayikilisha kwaye kuxabiseke ngakumbi.

- Oomatshini basusa ukuya kutsho kwi-98% yolwelo lwasimahla kwinkunkuma, ukusika inkunkuma eyingozi.

- Iinkqubo zeBriquetter zibuyisela ulwelo olulahlwayo, ukuze iinkampani ziphinde ziyisebenzise.

- Iinkqubo zokucocwa kwamanzi ziphinda zisebenzise amanzi, zithobe iindleko zokulahla kunye nokunceda ukuhlangabezana nemimiselo.

- Izityumzi ezisebenza ngombane kunye neenkqubo zokunciphisa uthuli zinciphisa ukukhutshwa kunye nokugcina umoya ucocekile.

Olu phuculo lunceda iinkampani ukuba zilandele imithetho yokusingqongileyo, zinciphise inkunkuma, kwaye zixhase ikamva elicocekileyo.

Ukudityaniswa kwe-AI kunye nokuFunda koMatshini kwiiNdawo zeCrusher

I-AI-Driven Failure Prediction for Parts Crusher

I-AI ngoku inceda amaqela aqikelele ukuba niniiindawo zokutyumzainokusilela. Iisistim ezihlakaniphile zibukela iimpawu ezifana nokungcangcazela, ubushushu kunye notshintsho loxinzelelo. Basebenzisa le datha ukubona iingxaki ngaphambi kokuba zenze uqhekeko. Umzekelo, iSBM's Smart Crusher Control System kwiplanti yentsimbi yaseKhanada yenze umahluko omkhulu. Isistim ilungelelanise useto ngexesha lokwenyani kunye nolondolozo olucwangcisiweyo phambi kokuba kwenzeke ukusilela. Oku kukhokelele ekunyukeni kwe-22% kwi-throughput, i-40% yeziganeko ezimbalwa zexesha lokuphumla, kunye ne-15% yokonga amandla. Abasebenzi bathembela ezi zixhobo ze-AI ukugcina oomatshini besebenza ixesha elide kwaye banqande izinto ezothusayo.

| Umgangatho wokuSebenza | Uphuculo oluyalelwa kuManyano lwe-AI |

|---|---|

| Ukwandiswa koMsebenzi | Ukunyuka kwe-22% (ukusuka kwi-550 TPH ukuya kwi-670 TPH) |

| Ukunciphisa ixesha lokuphumla | I-40% yeziganeko ezimbalwa zexesha lokuphumla |

| Ukonga Amandla | I-15% yokunciphisa ukusetyenziswa kwamandla |

| Ukwandiswa koBomi becandelo | I-15-20% ubude bobomi beendawo zokunxiba |

| Liner Replacency Frequency | I-35% yokunciphisa kumgodi wechromite waseTurkey |

Ukuqikelela ukusilela okuqhutywa yi-AI kuthetha ukuqikelela okuncinci kunye nexesha elingakumbi lomsebenzi ngamnye.

ULungiselelo lweNkqubo yokuSebenza kwiiNdawo zeCrusher

Ukufunda ngoomatshini ngoku kunceda izityuli zisebenze ngobukrelekrele, hayi nzima. Ulawulo oluzenzekelayo lulungelelanisa amaxabiso okutya kunye nesetingi ukugcina inkqubo izinzile. Oku kuthetha ubungakanani obuhambelanayo bemveliso kunye nomgangatho ongcono. Amaqela akusafuneki ukuba abukele zonke iinkcukacha. Inkqubo ifumana eyona ndlela ilungileyo yokuqhuba isityumzi kunye nemiba yamabala kwangoko. Idatha yexesha langempela inceda abaqhubi ukuba benze izigqibo ngokukhawuleza. Isondlo siyatshintsha ekulungiseni iingxaki emva kokuba ziye zayeka ngaphambi kokuba ziqale.

| Ubuchule beMetric | Inkcazo yoPhuculo |

|---|---|

| Ukusetyenziswa kwamandla | Ukuya kuthi ga kwi-30% yokunciphisa ngokuxhomekeke kwisicelo |

| Nxiba inxalenye yobomi bonke | Ukuphindaphinda kabini ukuya kane ukunyuka kokunxiba inxalenye yobomi bonke |

| Ixesha lokuphumla | Ukonyuka kwexesha lokuphumla ngenxa yotshintsho olumbalwa kunye nokuyeka |

| Ukuhambelana kweMveliso | Ubungakanani bemveliso obuhambelana ngakumbi ngenxa ye-automation eguqukayo |

Ukulungiselela okuzenzekelayo kuvumela amaqela ukuba akhulise ukusebenza ngaphandle kokuchitha ngaphezulu kwizixhobo ezitsha.

Amandla ekamva le-AI kwiCrusher Parts Technology

Ikamva lijongeka liqaqambile kwi-AI kwiindawo zokutyumza. Iingcali zilindele ukuba imarike ye-crusher yamatye ikhule ukusuka kwi-5.2 yeebhiliyoni zeedola kwi-2024 ukuya kwi-8.3 yeebhiliyoni zeedola ngo-2033. I-automation eqhutywa yi-AI, ukugcinwa kwangaphambili, kunye nokubeka iliso ngexesha langempela kuya kuqhuba oku kukhula. Izixhobo ezitsha ezifana nombono wekhompyuter kunye neerobhothi ziya kunceda amaqela asebenze ngokukhawuleza nangokukhuselekileyo. Ukufunda ngoomatshini kuya kugcina ukuphucula indlela abatyumza ngayo, kubenza basebenze ngakumbi kwaye bathembeke.

- Imakethi imiselwe ukuba ikhule nge-6.2% CAGR ukusuka ngo-2026 ukuya ku-2033.

- Ukuhlanganiswa kwe-AI kuya kugcina iindleko eziphantsi kunye nexesha lokuphumla.

- Iinkampani ziya kusebenzisa idatha eninzi ukwenza ukhetho olufanelekileyo kwaye uhlale phambili.

Njengoko i-AI iqhubeka nokuvela, iindawo zokutyumza ziya kuhlala ixesha elide, zisebenze, kwaye kulula ukuzilawula.

Itekhnoloji yezahlulo zeCrusher iqhubeka isiya phambili. Iinkampani ngoku zisebenzisa izixhobo ezikrelekrele, izixhobo ezingcono, kunye noyilo lokonga amandla. Olu tshintsho lunceda amaqela asebenze ngokukhawuleza kwaye onge imali. Kwakhona benza iindawo zokutyumza ixesha elide kwaye zinceda iplanethi. Nabani na ofuna ukuhlala phambili kule ntsimi kufuneka abukele ezi ndlela. Iimbono ezintsha kwiindawo zokutyumza ziya kuhlala zibumba ishishini kwiminyaka ezayo.

FAQ

Zeziphi iingenelo eziphambili zokusebenzisa iinxalenye ze-smart crusher?

Smartiindawo zokutyumzanceda amaqela abone iingxaki kwangethuba. Banciphisa ixesha lokunciphisa kwaye balondoloze imali ekulungiseni. Abaqhubi bafumana uhlaziyo lwexesha lokwenyani, ukuze bakwazi ukulungisa imiba ngaphambi kokuba ibe ziingxaki ezinkulu. Ezi nxalenye zikwanceda ukuba oomatshini bahlale ixesha elide.

Ziyiphucula njani imathiriyeli ephucukileyo yokusebenza kwenxalenye yecrusher?

Izixhobo eziphezulunjengealloyi ezikhethekileyo kunye neengubo zokwaleka zenza iindawo zokutyumza zibe nzima. Baxhathisa ukugqoka kunye nokushisa okungcono kunezixhobo ezindala. Oku kuthetha ukuba iindawo zihlala ixesha elide kwaye zifuna ukutshintshwa okumbalwa. Amaqela achitha ixesha kunye nemali encinci kulondolozo.

Ngaba iinxalenye zemodyuli zesityuli kulula ukuzifaka?

Ewe, iinxalenye zemodyuli zokutyumza zisebenzisa iinkqubo zokutshintsha ngokukhawuleza. Abasebenzi banokuzitshintsha ngokukhawuleza, rhoqo ngaphandle kwezixhobo ezizodwa. Oku kwenza ukufakela kukhuseleke kwaye kube lula. Amaqela achitha ixesha elincinane ekulungiseni kwaye afumane oomatshini abasebenzayo kwakhona ngokukhawuleza.

Ngaba iinxalenye ze-eco-friendly crusher zixabisa ngaphezulu?

Amalungu e-Eco-friendly crusher ngamanye amaxesha abiza kancinci ekuqaleni. Ngokuhamba kwexesha, bonga imali ngokuhlala ixesha elide kunye nokunciphisa inkcitho. Iinkampani ezininzi zifumana ukonga ixesha elide kunye neenzuzo zokusingqongileyo ezilufanele utyalo-mali.

Ixesha lokuposa: Jun-14-2025