A icone crusherithembele kwizinto ezikumgangatho ophezulu ukuphatha imisebenzi enzima, ngakumbi yayoamacandelo econe crusher. Intsimbi yeManganese, ngakumbi iHadfield steel, ilawula ukwakhiwa kwayo. Esi sixhobo sibonelela ngokuqina okumangalisayo kunye nokumelana nokunxiba, ngaphezulu kwe-12% yemanganese eqina ngexesha lokusetyenziswa. Intsimbi ekhandisiweyo kunye ne-ceramic composite nazo zomeleza ukuqina kwesityumzi sekhowuni, siqinisekisa ukuba simelana noxinzelelo olukhulu kunye neemeko ezirhabaxa.

Izinto eziphambili zokuThatha

- Intsimbi yeManganesesesona sixhobo siphambili kwizityuli zekhowuni. Yomelele kakhulu kwaye iyaxhathisa ukudinwa.

- Izixhobo ezomeleleyo njengemixube yeceramic zenza iinxalenye zihlale ixesha elide. Bakwanceda isityumzi sekhowunisebenza ngcono kwaye ufuna ukulungiswa kancinci.

- Ukukhetha izixhobo ezifanelekileyo kunye nohlengahlengiso lwezicwangciso kunokunceda kakhulu. Yenza i-crusher isebenze kakuhle kwaye ihlale ixesha elide.

Amacandelo e-Cone Crusher kunye nezixhobo zabo

Ingubo kunye neConcaves

Iingubo kunye ne-concavesngamacandelo abalulekileyo e-cone crusher anxibelelana ngokuthe ngqo nezinto ezityunyuziweyo. Ezi ndawo zenziwe ngentsimbi yemanganese, eqina phantsi koxinzelelo kwaye imelane nokunxiba. Ingubo ihleli phezu kweshafti engundoqo, ngelixa i-concave zenza isitya esimileyo esijikelezayo. Ngokudibeneyo, benza igumbi lokutyumza apho amatye axinzelelwe kwaye aphulwe.

Iingxelo zokusebenza zibonisa ukuba amazinga okunxiba kula macandelo axhomekeke kwizinto ezifana neempawu zentsimbi kunye neemetriki zokusebenza. Iindawo eziphakamileyo zokunxiba kwii-concave liners zihlala zivela phakathi kunye nezantsi kwimiqolo, ngelixa i-mantle ifumana ukunxitywa ngokulinganayo. Oku kubalaselisa ukubaluleka kokukhetha imathiriyeli ehlala ixesha elide kunye nokwandisa izicwangciso zesityumzi ukwandisa ubomi bala macandelo.

I-Shaft engundoqo kunye ne-Eccentric Bushing

Iishaft engundoqokunye ne-eccentric bushing ngumqolo wokusebenza kwecone crusher. I-shaft ephambili isekela i-mantle kwaye idlulisela amandla okutyumza, ngelixa i-eccentric bushing ivumela i-mantle ukuba ihambe kwi-gyratory motion. Ezi zixhobo zidla ngokuyilwa ukusuka kwintsimbi ephezulu kunye ne-alloys yobhedu ukunyamezela uxinzelelo olukhulu kunye namandla ajikelezayo abandakanyekayo.

- Imiba eqhelekileyo nge-eccentric bushing ibandakanya:

- Ukugqithiswa kweoli yokuthambisa

- Iifayili zobhedu kwiyunithi yesikrini se-hydraulic

- Ukuvalwa ngokupheleleyo kwesityumzi

- Izinto ezinegalelo ekudinweni kwebhutsi:

- Ukuthambisa okungafanelekanga

- Iilayini ezingalunganga okanye ulungelelwaniso olungachanekanga

- Izohlwayo ezigqithisileyo kwizinto zokutya

Xa udinwe kakhulu, amagcisa afanele achaze oyena nobangela, acoce aze apolishe ishafti engundoqo, aze alinganise iindawo ezonakeleyo ukuze zitshintshwe. Ulondolozo olufanelekileyo luqinisekisa ukuba la macandelo e-cone crusher asebenza ngokufanelekileyo kwaye ahlala ixesha elide.

Isakhelo kunye neNdlela yokuKhululwa kweTramp

Isakhelo sibonelela ngenkxaso yolwakhiwo kuwo onke amacandelo e-cone crusher. Ngokuqhelekileyo yenziwe ngentsimbi okanye intsimbi ukuqinisekisa ukuzinza kunye nokumelana nemithwalo enzima. Indlela yokukhulula i-tramp, kwelinye icala, ikhusela isityumzi kumonakalo owenziwe zizinto ezingenakucolwa njengenkunkuma yesinyithi.

Lo matshini usebenzisa iisistim ze-hydraulic ukukhulula uxinzelelo kunye nokuvumela izinto ezingagungqiyo ukuba zidlule ngokukhuselekileyo. Abavelisi bahlala besebenzisa i-ceramic composites kunye ne-high-grade steel kula macandelo ukuqinisekisa ukuqina nokuthembeka. Isakhelo esenziwe kakuhle kunye nendlela yokukhulula i-tramp inegalelo ekusebenzeni kakuhle kwe-crusher kunye nokhuseleko ngexesha lokusebenza.

Isizathu Sokuba Ezi Mxholo Zisetyenziselwe

Ukuqina kunye nokuNxitywa kweNgqondo

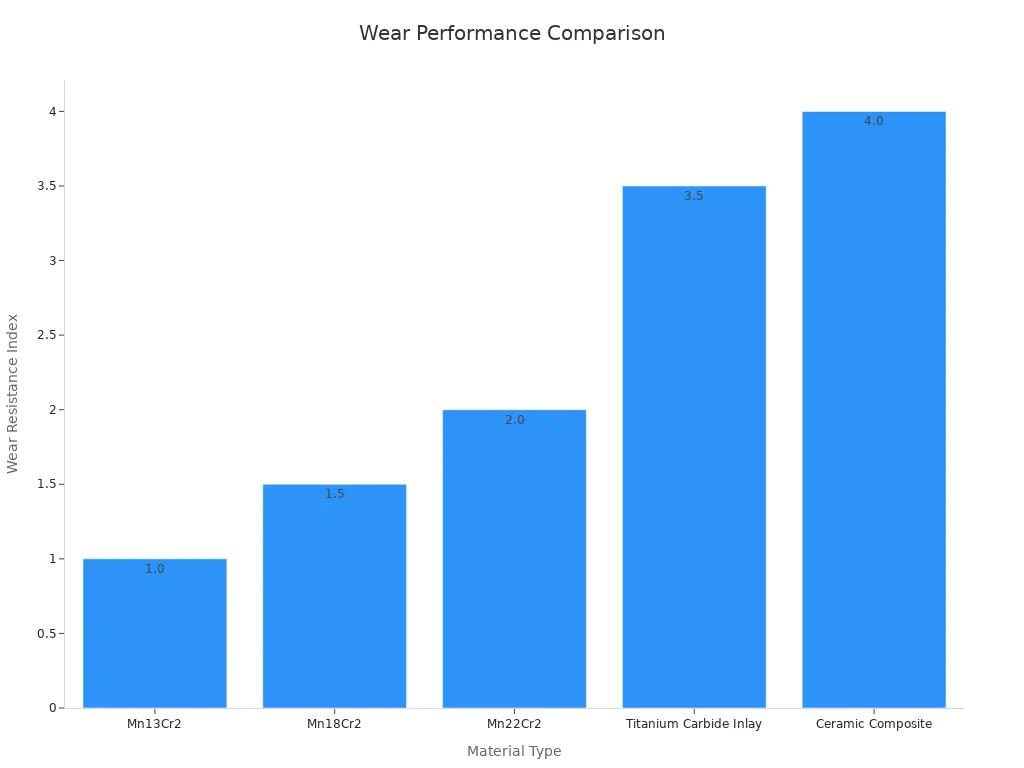

Amacandelo e-cone crusher ajongana nokuguga okugqithisileyo kunye nokukrazula ngexesha lokusebenza. Ukulwa nale nto, abavelisi basebenzisa izinto ezifanaintsimbi ye-manganese kunye ne-ceramic composites. Intsimbi yeManganese, ngakumbi amabanga afana ne-Mn13Cr2 kunye ne-Mn18Cr2, iyaqina phantsi koxinzelelo, iyenze ilungele ukutyumza imathiriyeli yokurhabula. Iicomposites zeCeramic, kwelinye icala, zibonelela ngobulukhuni obuphezulu kwaye zigcina iphrofayili yazo ebukhali yokutyumza naphantsi kweemeko ezinzima.

| Uhlobo lwezinto eziphathekayo | Ukuqina (HRC) | Nxiba i-Resistance Index | Ukuchasa impembelelo | Ubomi obulindelekileyo (iiyure) |

|---|---|---|---|---|

| Mn13Cr2 | 18-22 | 1.0 | ★★★★★ | 800-1200 |

| Mn18Cr2 | 22-25 | 1.5 | ★★★★☆ | 1200-1800 |

| I-Ceramic Composite | 60-65 | 4.0 | ★☆☆☆☆ | 3000-4000 |

Ezi zixhobo ziqinisekisa ukuba i-crusher inokusingatha ukusetyenziswa ixesha elide ngaphandle kokutshintshwa rhoqo, ukunciphisa ixesha lokunciphisa kunye neendleko zokugcina.

Amandla ezicelo zoxinzelelo oluphezulu

Izityumza zecone zisebenza phantsi koxinzelelo olukhulu, ngakumbi xa kusetyenzwa izinto eziqinileyo njengequartz okanye igranite.Intsimbi ephezulu kunye ne-titanium carbideinlay zisetyenziswa ngokuqhelekileyo kumacandelo afana neshaft engundoqo kunye ne mantle. I-Titanium carbide inlays, umzekelo, ukuphucula ukuxhathisa ukunxiba ngamaxesha e-1.8 kunye nefuthe lokuqina ngamaxesha e-8.8 xa kuthelekiswa nezinto eziqhelekileyo. La mandla aqinisekisa ukuba i-crusher inokusingatha izicelo zoxinzelelo oluphezulu ngaphandle kokunciphisa ukusebenza.

Ukuziqhelanisa neeMfuno ezahlukeneyo zokutyumza

Imisebenzi ehlukeneyo yokutyumza ifuna izinto ezinokuziqhelanisa neemeko ezahlukeneyo. Umzekelo, i-Mn18Cr2 iyagqwesa ekuphatheni izinto ezingaqhelekanga ezinobumdaka ngenxa yokuchasana kwayo nempembelelo. Iicomposites zeCeramic zifaneleke ngcono ukutyunyuzwa kwezinto ezinobunzima obukhulu. Iimvavanyo zentsebenzo kusetyenziswa ukulinganisa kwamanani, okufana nendlela yento edityanisiweyo (DEM), ibonise ukuba ukwenza iiparamitha ezingcono njengesantya sokujikeleza kunye nee-engile zekhowuni kunokuphucula ngakumbi ukuguquguquka. I-Y51 cone crusher, umzekelo, iphumelele imveliso ephezulu kunye ne-angle yangaphambili ye-1.5 ° kunye nesantya sokujikeleza se-450 rad / min.

Ngokukhetha izixhobo ezifanelekileyo kunye nolungelelwaniso, amacandelo e-cone crusher angahlangabezana neemfuno ezahlukeneyo zokusebenza ngelixa ugcina ukusebenza kakuhle.

IiMathiriyeli ziyichaphazela njani ukusebenza kweCrusher

Impumelelo eyongeziweyo kunye nobomi obude

Izinto ezisetyenziswa kumacandelo e-cone crusher zidlala indima enkulu ekuphuculeni ukusebenza kakuhle kunye nokwandisa ubomi bomatshini. Izinto ezikumgangatho ophezulu ezifana nentsimbi yemanganese kunye neecomposites zeceramic ziqinisekisa ukuba iinxalenye ziyakwazi ukusingatha umsebenzi onzima ngaphandle kokuguga ngokukhawuleza. Ngokomzekelo, izinto ezixhathisayo zingahlala ziphindwe kabini ukuya kwezine kunezo zendabuko, ukunciphisa isidingo sokutshintshwa rhoqo.

| Ubungqina | Inkcazo |

|---|---|

| Izinto ezikumgangatho ophezulu | Isetyenziselwa ukwenza iindawo ezomeleleyo. |

| Izinto zokunxiba ezixhathisayo | Ukuphucula ukuqina, ukuhlala kwi-2 ukuya kumaxesha ama-4 ubude. |

Izinto ezihlala zihlala zinciphisa ukulahleka kwamandla ngexesha lokusebenza. Uphononongo lubonise ukuba ii-crushers ezakhiwe ngezixhobo ezomeleleyo zifumana ukuguga nokukrazuka okuncinci, okuthetha ukuba zigcina ukusebenza kwazo ngokuhamba kwexesha. Oku komelela kuqinisekisa ukuba i-crusher isebenza ngokufanelekileyo, naphantsi kweemeko ezinzima.

| Ubungqina | Inkcazo |

|---|---|

| Izityumli zecone ezikumgangatho ophezulu | Yenzelwe ukuba ihlale ngemathiriyeli enganyangekiyo. |

| Izinto ezomeleleyo | Ukukhokelela ekunxibeni okuncinci kunye nokukrazula, ukuphucula ukusebenza kakuhle. |

ULondolozo oluNcitshisiweyo kunye nexesha lokuphumla

Ukugcinwa rhoqo kunokuphazamisa ukusebenza kunye nokwandisa iindleko. Ngokusebenzisa izinto ezomeleleyo nezingagugiyo, abavelisi banciphisa imfuno yokulungiswa. Ngokomzekelo, intsimbi ye-manganese iyaqina phantsi koxinzelelo, iyenze ilungele iindawo ezifana nengubo kunye ne-concaves. Le propati inciphisa izinga lokunxiba, ivumela i-crusher ukuba iqhube ixesha elide ngaphandle kokuphazamiseka.

Uphononongo olukhulu ngo-1982 lwalinganisa amandla okuqhekeka kunye neempawu zokuqhekeka kwentsimbi kwizityuli zemveliso. Iziphumo zabonisa ukuba ukusebenzisa izinto ezikumgangatho ophezulu kunciphisa kakhulu ukuphazamiseka kokusebenza. Iisampulu ezivela kuphononongo zavavanywa ngeenkqubo ze-pendulum ezinamandla, eziqinisekisa amandla ezinto zokumelana neemeko ezinzima.

Ukongeza, ukhetho lwezinto eziphathekayo luchaphazela indlela i-crusher ephethe ngayo amanqanaba ahlukeneyo omqolo. IiCrushers ezisebenza ngemingxuma epheleleyo kunye nezixhobo zamatye aqinileyo zibonisa ukusebenza kakuhle kwemveliso. Kwelinye icala, imisebenzi ye-low-cavity enezixhobo zamatye ezithambileyo zihlala zikhokelela ekusebenzeni okuguquguqukayo, kufuna uhlengahlengiso oluthe kratya.

| Inqanaba leCavity | Uhlobo lwezinto eziphathekayo | Iimpembelelo eziqwalaselweyo |

|---|---|---|

| Umgodi ophantsi | Ilitye elithambileyo | Ukunyuswa kokusetyenziswa kwamandla. |

| Umgodi ophezulu | Ilitye elinzima | Iipropati zokunciphisa eziphuculweyo. |

Ukuphuculwa kokuCrushing Precision

Izinto ezifanelekileyo zikwanyusa ukuchaneka kwenkqubo yokutyumza. Ngokomzekelo, ii-composites ze-ceramic zigcina iphrofayili yazo ebukhali, nasemva kokusetyenziswa ixesha elide. Oku kuhambelana kuqinisekisa ukuba isityuli sivelisa izinto ezinobungakanani obufanayo, obubalulekileyo kumashishini afana nokwakha kunye nemigodi.

Iisistim zokulawula ukunciphisa ubungakanani ezizenzekelayo ziphucula ngakumbi ukuchaneka. I-Crushers exhotyiswe ngezi nkqubo zifumana i-38-46% inguqu engaphantsi kwiimetriki zokusebenza. Imveliso ehambelanayo iphinda ikhulise ukusebenza kwesekethe ye-avareji nge-12-16%, okwenza i-crusher ithembeke ngakumbi.

| Iziphumo eziphambili | Impembelelo kuMsebenzi |

|---|---|

| Ulawulo lokunciphisa ubungakanani oluzenzekelayo | I-38-46% inguqu ephantsi kwiimetriki zokusebenza. |

| Ukuhambelana kwimveliso | I-12-16% ukunyuka komsebenzi wesekethe. |

Ngokudibanisa imathiriyeli ephucukileyo kunye nobunjineli obuchanekileyo, amacandelo e-cone crusher ahambisa umsebenzi obalaseleyo. Olu luhlu aluphuculi nje ukuchaneka kokutyumza kodwa luqinisekisa ukuba umatshini uhlangabezana neemfuno zezicelo ezahlukeneyo.

Izinto ezisetyenziswa kwizityuli zekhowuni zibalulekile ekomeleleni kwazo kunye nokusebenza kakuhle. Intsimbi ye-Manganese, intsimbi yekhabhoni, i-ceramic composites, kunye nentsimbi ephosiweyo iqinisekisa ukuba aba matshini bayakwazi ukusingatha izicelo ezinzima kwaye baxhathise ukunxiba ixesha elide.

- Izityuli ze-cone ziphucula ukusebenza kakuhle kwamandla nge-10-30%, ukunciphisa iindleko zokusebenza.

- I-Crushers igcina imveliso engaguqukiyo yobukhulu obufanayo bezinto eziphathekayo, nokuba kukho ukuhluka kuyilo lwegumbi.

- Iingcali zemizi-mveliso zigxininisa ekuphuculeni iindawo zokunxiba kunye nokulungelelaniswa kwegumbi ukusebenza ngcono kunye nokuphila ixesha elide.

Ukhetho olululo lwemathiriyeli alonyusi nje ukuthembeka kwesityumzi kodwa lukwaxhasa imfuno yoshishino lwezimayini yokusetyenzwa kwe-1.3 yezigidi zeetoni zamatye ngonyaka. Ngokulungelelanisa uyilo kunye nezinto eziguquguqukayo zokusebenza, izityuli zekhowuni zizisa iziphumo ezifanayo kuzo zonke iintlobo zezicelo.

FAQ

Ngawaphi awona malungu abalulekileyo e-cone crusher?

Ingubo, i-concaves, i-shaft engundoqo, i-eccentric bushing, kunye nefreyimu zizinto eziphambili. Inxalenye nganye idlala indima ebalulekileyo kwinkqubo yokutyumza.

Izinto zichaphazela njani ukusebenza kwamacandelo e-cone crusher?

Izinto ezikumgangatho ophezulu ziphucula ukuqina,ukunciphisa ukunxiba, kunye nokwandisa ukusebenza kakuhle. Baqinisekisa ukuba i-crusher isebenza kakuhle, naphantsi kweemeko ezinzima.

Kutheni le nto intsimbi yemanganese isetyenziswa ngokuqhelekileyo kumacandelo econe crusher?

Intsimbi yeManganese iyaqina phantsi koxinzelelo, iyenze ilungele ukutyumza izinto ezirhawuzelayo. Ukomelela kwayo kwandisa ubomi beendawo ezibalulekileyo njengengubo kunye ne-concaves.

Ixesha lokuposa: Jun-03-2025