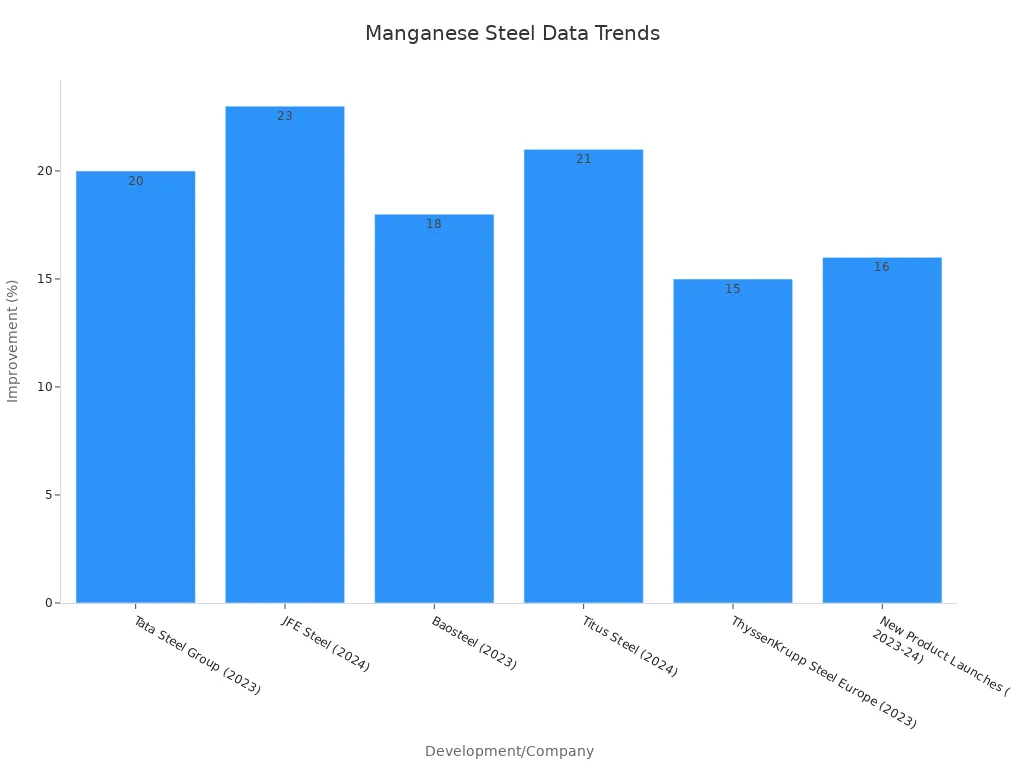

Intsimbi yeManganesesisixhobo esiphambili kwishishini elinzima, elaziwa ngamandla alo akhethekileyo, ukuqina, kunye nokumelana nokunxiba ukuba izinto ezimbalwa zinokuhambelana.High Mn Steel, kubandakanywa i-Manganese Steel Plates kunye ne-Manganese Steel Castings, iqinisekisa ukuba oomatshini basebenza ngokufanelekileyo naphantsi kweemeko ezinzima. Iinkampani zifumana amava ukuya kuthi ga kwi-23% yokuphucula ukusebenza kunye nobomi benkonzo obandisiweyo, njengoko kubonisiwe ngezantsi:

Izinto eziphambili zokuThatha

- Intsimbi yeManganeseyomelele kakhulu kwaye yomelele ngenxa yesiqulatho sayo semanganese ephezulu, esinceda ukuba sibenzima xa sibethiwe okanye sicinezelwe.

- Le ntsimbi ixhathisa ukunxiba, impembelelo, kunye nokugqwala okungcono kunezinye iintsimbi ezininzi, okwenza kube yinto efanelekileyo kumashishini anzima ajongene neemeko ezinzima.

- Amashishini afana nemigodi, ulwakhiwo, kunye noololiwe baxhomekeke kuwointsimbi yemanganeseukugcina izixhobo zikhuselekile, zihlala ixesha elide, kwaye zisebenza ixesha elide ngokulungiswa okuncinci.

Intsimbi yeManganese: Ukuqulunqwa kunye neempawu ezikhethekileyo

Yintoni eyahlula iManganese Steel

Intsimbi yeManganese ibalasele ngenxa yomxube wayo okhethekileyo wezinto. Uninzi lweentlobo ziqulethe malunga ne-10-14% ye-manganese kunye ne-1-1.4% yekhabhoni, kunye nezinye ziyintsimbi. Ezinye iintsimbi eziphezulu zemanganese ezisetyenziswa emigodini okanye koololiwe zinokuba ne-30% yemanganese. Lo mxholo wemanganese uphezulu unika intsimbi amandla ayo adumileyo kunye nokuqina. Iingcali zenzululwazi ziye zafumanisa ukuba i-manganese iyayitshintsha indlela intsimbi eyenza ngayo kwaye iguqule. Inceda intsimbi ihlale yomelele kwaye yomelele, nangona ijongene nokubetha okanye imithwalo enzima.

Uphando lwenzululwazi yezinto eziphathekayo lubonisa ukuba intsimbi yemanganese ine-microstructure ekhethekileyo. Xa intsimbi igoba okanye isolula, utshintsho oluncinci lwenzeka ngaphakathi. Olu tshintsho, olubizwa ngokuba yi-TWIP kunye ne-TRIP effects, lunceda intsimbi ukuba yomelele ngakumbi ngaphandle kokwaphuka. Intsimbi ikwazi ukugcina amandla ayo kumaqondo obushushu ukusuka -40 ukuya 200 °C.

Itheyibhile engezantsi ibonisa ukwakheka okuqhelekileyo kwentsimbi yemanganese xa kuthelekiswa nezinye iintsimbi:

| I-Alloying Element | Ipesenteji yoBumetho obuqhelekileyo (wt%) | Uluhlu okanye amanqaku |

|---|---|---|

| Ikhabhoni (C) | 0.391 | Isiqheloipleyiti yentsimbi yemanganese |

| IManganese (Mn) | 18.43 | Ipleyiti yentsimbi yemanganese eqhelekileyo |

| I-Chromium (Cr) | 1.522 | Ipleyiti yentsimbi yemanganese eqhelekileyo |

| IManganese (Mn) | 15 – 30 | Iintsimbi eziphezulu-manganese |

| Ikhabhoni (C) | 0.6 - 1.0 | Iintsimbi eziphezulu-manganese |

| IManganese (Mn) | 0.3 - 2.0 | Ezinye iintsimbi ze-alloy |

| IManganese (Mn) | >11 | Iintsimbi ze-Austenitic zokumelana nokunxiba okuphezulu |

Ukuthelekisa nezinye iintsimbi

Intsimbi yeManganese isebenza bhetele kunezinye iintsimbi ezininzi kwimisebenzi enzima. Inamandla aphezulu okunyamezela kwaye inokusingatha impembelelo engaphezulu. Intsimbi iphinda ibenzima xa ibethwa okanye icinezelwe, nto leyo enceda ukuba ihlale ixesha elide kwiindawo ezirhabaxa njengemigodi okanye oololiwe.

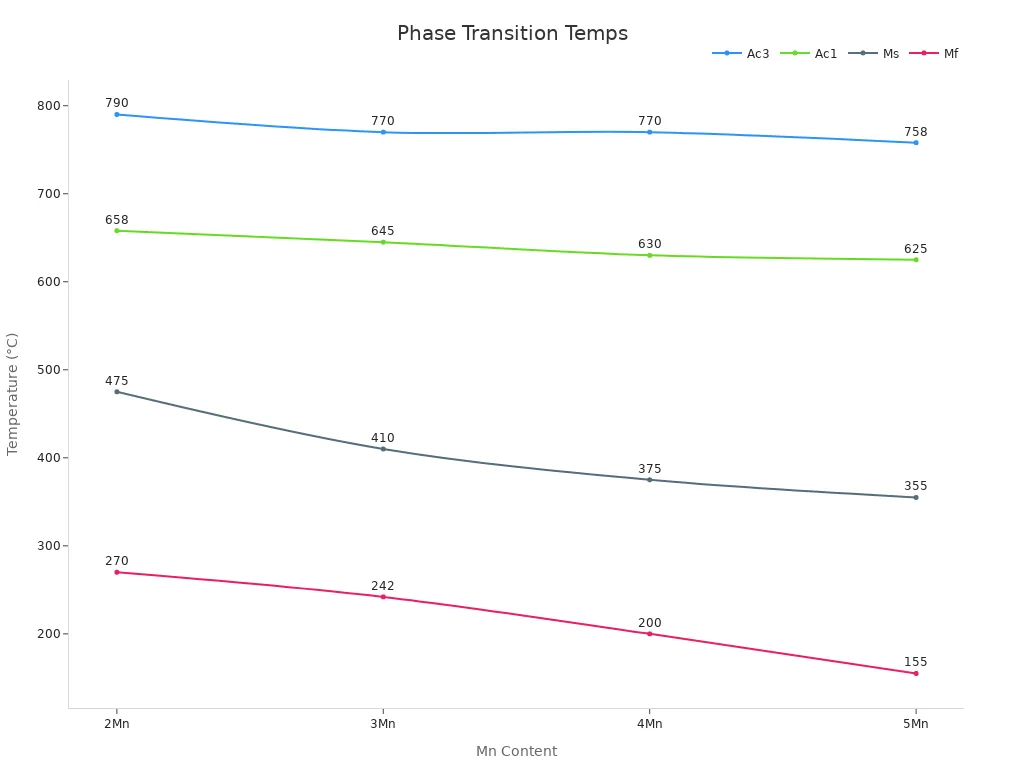

Itshathi engezantsi ibonisa indlela umxholo wemanganese ukuchaphazela ngayo amandla entsimbi kunye notshintsho lwesigaba:

Xa kuthelekiswa nentsimbi engatyiwayo, intsimbi yemanganese inokumelana nempembelelo engcono kunye nokumelana nokunxiba. Intsimbi engatyiwayo imelana nomhlwa ngcono, kodwa intsimbi yemanganese lolona khetho luphezulu lweendawo apho izixhobo zijongene nokubetha kunye nemikrwelo emininzi.

Ingcebiso:Intsimbi yeManganese inzima ukuyitshintshakuba iya iqina njengoko usebenza kuyo. Abasebenzi basoloko besebenzisa izixhobo ezikhethekileyo zokuyisika okanye ukuyibumba.

IiPropathi eziPhambili zeManganese Steel kuShishino

Impembelelo kunye nokunyangwa kwe-Abrasion

Intsimbi yeManganese ibalasele ngokukwazi kwayo ukuphatha iibethi ezinzima kunye nonyango olurhabaxa. Kumashishini anzima, oomatshini bahlala bejongana namatye, igrabile, kunye nezinye izinto ezinzima. Xa ezi mathiriyeli zibetha okanye zikhuhla kwintsimbi, iintsimbi ezininzi zikhawuleza ziwohloke. Intsimbi yeManganese, nangona kunjalo, iyomelela ngempembelelo nganye. Oku kwenzeka ngenxa yokuba isakhiwo sayo sitshintsha phantsi koxinzelelo, okwenza umphezulu ube nzima ngelixa ugcina ngaphakathi.

Abaphandi bavavanya intsimbi yemanganese ngokuyibetha nge-tungsten-carbide striker kwi-lab. Bongeza amasuntswana entsimbi abukhali ukwenza uvavanyo lube nzima ngakumbi. Intsimbi ibambe kakuhle, ibonisa ukuguga okuncinci nasemva kweempembelelo eziphindaphindiweyo. Kolunye uvavanyo, iinjineli zasebenzisaizityumzi zemihlathiukucola igrabile. Imihlathi yentsimbi yemanganese yaphulukana nobunzima obuncinci kwaye yahlala igudile kunezinye iintsimbi. Iingcali zenzululwazi zifumene iinkozo ezincinci kunye neepateni ezikhethekileyo ngaphakathi kwentsimbi emva kolu vavanyo. Olu tshintsho lunceda isinyithi sixhathise ukusika kunye nokubola.

Ubusazi? Intsimbi yeManganese iya isiba nzima ngokuye isebenza. Oku "ukuqina komsebenzi" kwenza ukuba kusebenze kakuhle kwimigodi, ukugrumba, kunye nezixhobo zokutyumza.

Iinjineli zikwasebenzisa iingubo zentsimbi yemanganese kwiindawo ezityibilika okanye ezihlikihlayo kunye, njengemizila kaloliwe kunye nezikhokelo zokugawula amalahle. Ezi zogquma zihlala ixesha elide kwaye zixhathise umonakalo ovela kwimithwalo enzima kunye nokuhamba rhoqo. Imfihlelo ilele kumxube wezinto kunye nendlela intsimbi etshintsha ngayo xa igxininisekile.

Ukuqina kunye nokuqina

Ukuqina kuthetha ukuba isixhobo sinokuhlala ixesha elide, nokuba sisetyenziswa yonke imihla. Ukuqina kuthetha ukuba kunokuthatha ukubetha ngaphandle kokwaphuka. Intsimbi yeManganese ifumana amanqaku aphezulu kuzo zombini iindawo. Uphononongo lwaseLab lubonisa ukuba intsimbi ephakathi yemanganese inokolula ngaphezulu kwe-30% phambi kokuba yophuke kwaye inamandla okuqina ngaphezulu kwe-1,000 MPa. Oku kuthetha ukuba inokugoba kwaye iguquke ngaphandle kokuhlutha.

Xa oomatshini besebenza iiyure okanye iintsuku, amalungu abo ajamelana noxinezeleko oluphindaphindiweyo. Intsimbi yeManganese iyiphatha kakuhle le nto. Uvavanyo lubonisa ukuba iyamelana neentanda kunye nokulibazisa umonakalo, nokuba ilayishwe kwakhona kwaye kwakhona. Iingcali zenzululwazi zisebenzisa iimodeli ezikhethekileyo ukuqikelela ukuba intsimbi iya kuziphatha njani ngokuhamba kwexesha. Le mizekelo ibonisa ukuba intsimbi yemanganese iqhelana noxinzelelo, isasazeke umonakalo, kwaye igcina ukusebenza ixesha elide kunezinye iintsimbi ezininzi.

- Uvavanyo lokuthelekisa ukuqina luqaqambisa ukuqina kwentsimbi yemanganese:

- Ubunzima kunye novavanyo lwamandla empembelelo lubonisa ukuba iintsimbi ze-vanadium manganese eziphezulu zibetha intsimbi ye-Hadfield yendabuko.

- Iimvavanyo ze-pin-on-disk kunye ne-ball mill zibonisa ukuba i-manganese yentsimbi yokuxhathisa inxiba ngcono kunezinye ii-alloys eziphezulu.

- Uvavanyo lwe-tensile lubonisa ukuba iintsimbi ze-manganese ezidibeneyo zihlala zomelele kwaye zibhetyebhetye, nakwizantya ezahlukeneyo zokolula.

- Ukongeza izinto ezifana nechromium, i-tungsten, kunye ne-molybdenum yenza intsimbi yomelele kwaye imelane nokunxiba.

Qaphela: Ulwakhiwo olukhethekileyo lwentsimbi yemanganese lunceda ukuba lufunxe amandla kwaye lucothise iintanda. Oku kugcina oomatshini besebenza ngokukhuselekileyo kwaye kunciphisa imfuneko yokulungiswa.

Ukunyangwa kokuMhlwa

Ukonakala kwenzeka xa isinyithi sidibana namanzi, umoya, okanye iikhemikhali kwaye siqalisa ukuwohloka. Kwiindawo ezifana nemigodi okanye kufuphi nolwandle, umhlwa unokonakalisa izixhobo ngokukhawuleza. Intsimbi yeManganese inika ukhuseleko olulungileyo, ngakumbi xa iphathwa ngezinto ezongezelelweyo ezifana nemolybdenum okanye ichromium. Ezi zinto zinceda ukwenza umaleko omncinci, ozinzile kumphezulu wentsimbi. Lo maleko uthintela amanzi kunye neekhemikhali, unciphisa umhlwa kunye nomnye umonakalo.

Uvavanyo lwaseLab lubonisa ukuba intsimbi yemanganese enemolybdenum kunye nonyango olukhethekileyo lobushushu luxhathisa umhlwa ngcono kakhulu. Izazinzulu zisebenzisa imikroskopu ukubona ezi maleko zikhuselayo. Bakwaqhuba iimvavanyo zombane ukulinganisa ukuba intsimbi idla ngokukhawuleza kangakanani na. Iziphumo zibonisa ukuba intsimbi yemanganese enyangweyo ihlala ixesha elide kwiindawo ezirhabaxa.

Nangona kunjalo, kwiindawo ezine-acidic kakhulu, intsimbi ye-manganese isenokujongana neengxaki ezifana nokugoba okanye ukuqhekeka. Yiyo loo nto iinjineli zihlala zongeza ezinye izinto okanye zisebenzise unyango olukhethekileyo ukomeleza ukuxhathisa.

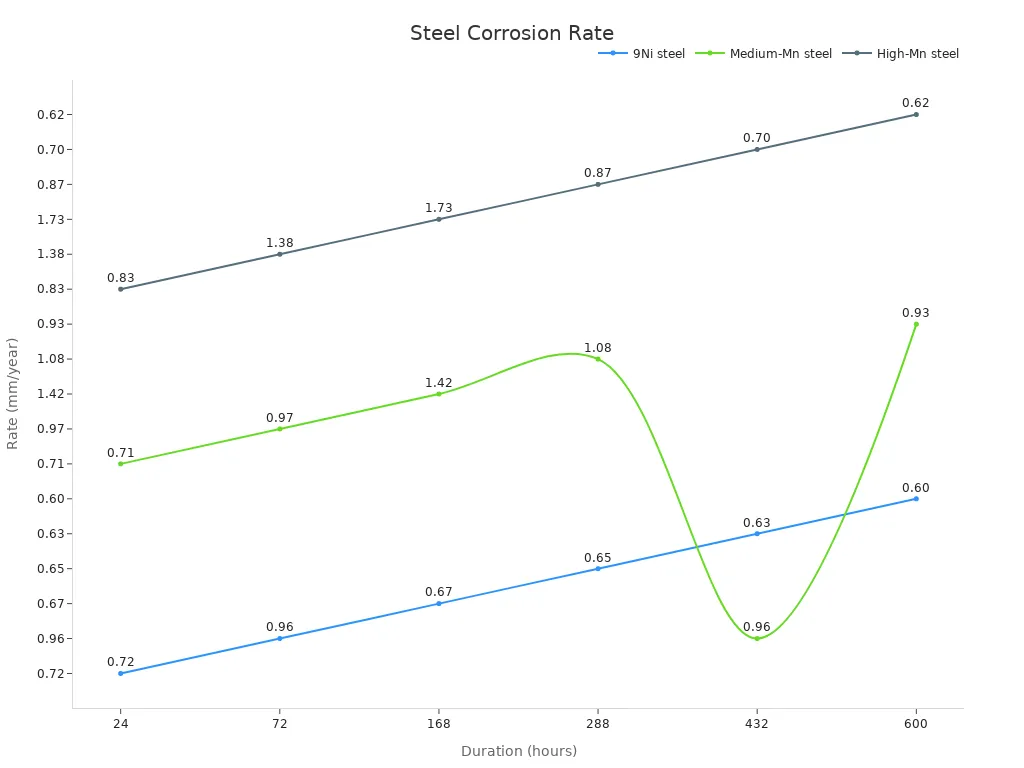

Itheyibhile engezantsi ithelekisa indlela ezikhawuleza ngayo ukubola kweentsimbi kwindawo engqonge ulwandle:

| Ubude bexesha lokutya (iiyure) | 24 | 72 | 168 | 288 | 432 | 600 |

|---|---|---|---|---|---|---|

| 9Ni intsimbi | 0.72 | 0.96 | 0.67 | 0.65 | 0.63 | 0.60 |

| Intsimbi ephakathi-Mn | 0.71 | 0.97 | 1.42 | 1.08 | 0.96 | 0.93 |

| High-Mn intsimbi | 0.83 | 1.38 | 1.73 | 0.87 | 0.70 | 0.62 |

Isantya sokutya kwentsimbi yeManganese siyehla ngokuhamba kwexesha njengemifanekiso yefilimu ekhuselayo. Oku kuyinceda ukuba ihlale ixesha elide, nakwindawo ezimanzi okanye ezinetyuwa. Iintsimbi ze-manganese ezithwala i-Chromium nazo zicothisa ukubola kwaye zinciphisa umngcipheko weentanda kwi-hydrogen.

Ingcebiso: Ngezona ziphumo zintle kwiindawo ezirhabaxa, iinjineli zikhetha intsimbi yemanganese eyongeziweyo ngechromium okanye imolybdenum kwaye isebenzise unyango olukhethekileyo lobushushu.

Intsimbi yeManganese kwiMisebenzi yoShishino lokwenyani lweHlabathi

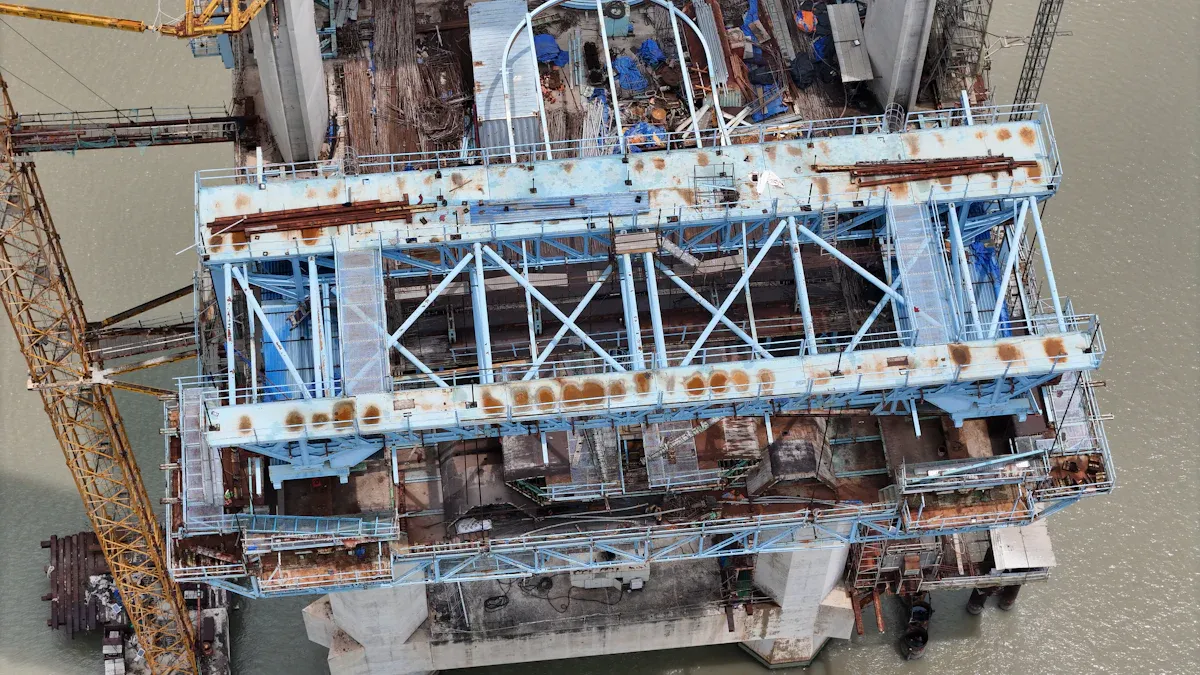

IZixhobo zokwembiwa kwemigodi nezakwakwari

Ukwembiwa kwemigodi kunye nokwembiwa kwezinto kubeka izixhobo kwiimeko ezinzima. Abasebenzi basebenzisa oomatshini abatyumza, basila, nabashukumisa amatye anzima mihla le. Intsimbi yeManganese inceda aba matshini bahlale ixesha elide. Uvavanyo loshishino lubonisa ukubaintsimbi yemanganese ephakathi, njenge-Mn8 / SS400, ilahlekelwa ubunzima obungaphantsi kokugqoka kunezinye iintsimbi. Ngaphezulu kweeyure ezingama-300, le ntsimbi ilahlekelwe malunga ne-69% ubunzima obungaphantsi kuneentsimbi ze-martensitic eziqhelekileyo. Nangona ingeyiyo eyona inzima, ifunxa amandla amaninzi kwaye ime ukuze ibe neempembelelo ezingcono. Oku kuthetha ukuba iinkampani zemigodi zinokusebenzisa izixhobo zazo ixesha elide kwaye zichithe kancinci ekuzilungiseni.

Ingcebiso: Ukukwazi kwentsimbi ye-manganese ukuba yomelele xa ibetha iyenza igqibeleleizityumzi zemihlathi, iihoppers, kunye neeliner kwimigodi.

Oomatshini bokwakha kunye neZiseko zoPhuhliso

Iindawo zokwakha zifuna izixhobo ezomeleleyo nezikhuselekileyo. Intsimbi yeManganese inika zombini. Inceda oomatshini baphathe imithwalo enzima kunye nonyango olurhabaxa. Itheyibhile engezantsi ibonisa indlela iintlobo ezahlukeneyo zentsimbi ye-manganese eziphucula ngayo ukhuseleko kunye nokuqina ekwakhiweni:

| Uhlobo lwentsimbi | Umxholo weManganese (%) | IiNzuzo eziPhambili |

|---|---|---|

| Hadfield Steel | 12 – 14 | Ukuchasana nokunxiba okuphezulu, ukuqina komsebenzi |

| Intsimbi yeCarbon-Manganese | Iyahluka | Yomelele, iqinile, kulula ukuyidibanisa |

Abakhi basebenzisa intsimbi ye-carbon-manganese ephantsi kwimiqadi kunye neentsika. Iintlobo zekhabhoni ephezulu zisebenza kakuhle koomatshini abanzima. Ezi ntsimbi zigcina imilo namandla azo, nokuba zisetyenziswa yonke imihla. Iinkampani zokwakha zikhetha intsimbi yemanganese kuba ihlala ixesha elide kwaye igcina abasebenzi bekhuselekile.

Ishishini lezoThutho kunye noLoliwe

Oololiwe kunye noololiwe bafuna izinto ezikwaziyo ukujongana noxinzelelo oluqhubekayo. Iintsimbi eziphakamileyo zemanganese, njengentsimbi yeHadfield, zisebenza kakuhle kumzila kaloliwe kunye neenxalenye. Ezi ntsimbi ziba nzima njengoko oololiwe bedlula phezu kwazo. Abaphandi bafumanise ukuba ukongeza ichromium kwenza intsimbi ibenamandla kwaye izinze ngakumbi. I-microstructure yensimbi iyatshintsha ngexesha lokusetyenziswa, enceda ukuxhathisa ukuguga kunye nomonakalo. Iinkampani zikaloliwe ziyayithemba intsimbi yemanganese ngokukhuseleka kwayo kunye nobomi obude. Iimodeli zekhompyuter zibonisa ukuba imele imithwalo ephindaphindiweyo esuka koololiwe abakhawulezayo, igcina imikhondo ikhuselekile kwaye yomelele.

- Iintsimbi eziphezulu zemanganese zizenza lukhuni phantsi kwemithwalo enzima.

- I-Chromium yongeza ubulukhuni kunye nokuzinza.

- Utshintsho lweMicrostructure lunceda ukuxhathisa ukunxiba kunye nokurhubuluza.

Qaphela: Oololiwe baxhomekeke kwintsimbi yemanganese ukunciphisa ukulungiswa nokugcina oololiwe bebaleka ngokukhuselekileyo.

Intsimbi yeManganese ibalasele kushishino olunzima. Iinkampani zibona izibonelelo zokwenyani:

- Amandla anempembelelo ephezulu kunye nokumelana nokunxiba kugcina izixhobo zisebenza ixesha elide.

- Iindlela zokutshiza ngobuchule, njengokufudumeza kwe-induction kunye nezixhobo ze-carbide, zonyusa imveliso.

- Ukuqina kwayo kunye nokukwazi ukuqinisa umsebenzi kunceda ukufunxa iimpembelelo ezinzima kunye nokuxhathisa ukuguga.

FAQ

Yintoni eyenza intsimbi yemanganese yomelele?

Intsimbi yeManganese yomelela xa ibetha. Yaloumxube okhethekileyo wezintoinceda ekuxhathiseni izibonda kunye neentanda, nakwimisebenzi erhabaxa.

Ngaba uyakwazi ukuwelda okanye ukusika intsimbi yemanganese ngokulula?

Ukuwelda kunye nokusika intsimbi ye-manganese kunokuba nzima. Abasebenzi basebenzisa izixhobo ezikhethekileyo kunye neendlela kuba intsimbi iyaqina njengoko besebenza kuyo.

Apho abantu basebenzisa intsimbi yemanganese kakhulu?

Abantu babona intsimbi yemanganese emigodini, koololiwe nasekwakhiweni. Isebenza kakuhle kwiindawo apho oomatshini bajongana neempembelelo ezininzi kunye nokunxiba.

Ixesha lokuposa: Jun-19-2025